Impermeable concrete and preparation method thereof

A technology of impermeable concrete and mixed solution, which is applied in the field of concrete, and can solve problems such as adverse effects on concrete strength and poor foam stability, and achieve the effects of improved impermeability, low strength, and high impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

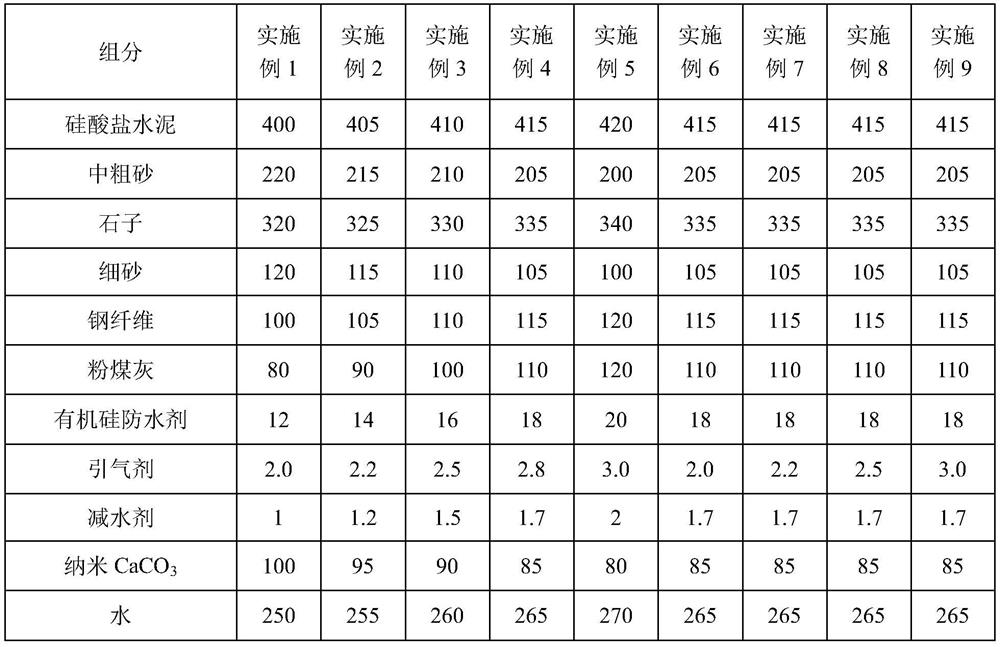

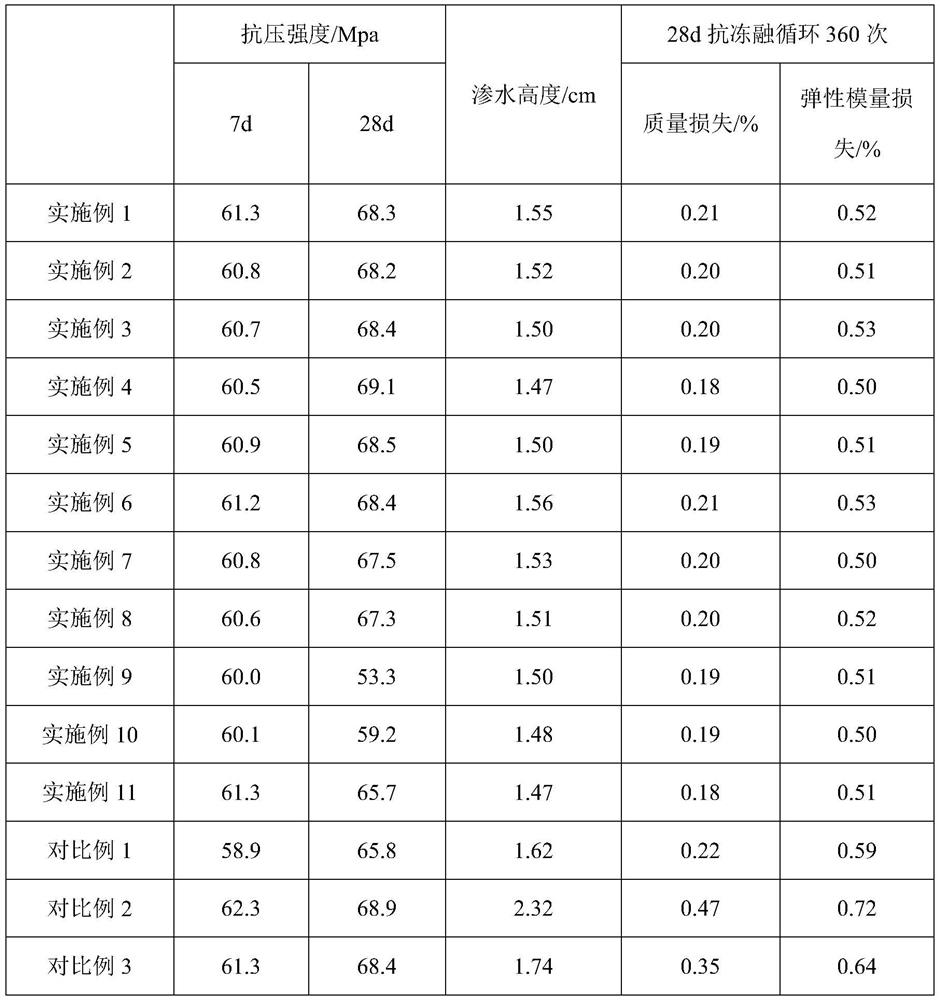

Examples

preparation example 1

[0045] The air-entraining agent of preparation example 1, its each raw material and the amount of each raw material are as shown in table 1, and its preparation step is:

[0046] 1) Add diethanolamine to DMF, stir evenly, then add maleic anhydride with the same molar weight as diethanolamine, and stir for 5 hours at 20°C to obtain a mixed solution A;

[0047] 2) Add triethanolamine to the mixed solution A, then add toluenesulfonic acid and toluene, and stir and react for 8 hours at 110°C to obtain the mixed solution B;

[0048] 3) After heating the rosin to 100°C, stir for 5 hours;

[0049] 4) Add the heat-treated rosin in step 3) into the mixed solution B, and then stir and react for 9 hours at a temperature of 100° C. to obtain the mixed solution C;

[0050] 5) Distill the mixed solution C under reduced pressure to obtain the air-entraining agent used in this application.

[0051] Each reactant and consumption (kg) of the air-entraining agent of table 1 preparation example...

preparation example 2

[0054] The air-entraining agent of preparation example 2, its each raw material and the amount of each raw material are as shown in table 1, and its preparation step is:

[0055] 1) Add diethanolamine to DMF, stir evenly, then add maleic anhydride with the same molar weight as diethanolamine, and stir for 4 hours at 25°C to obtain a mixed solution A;

[0056] 2) Add triethanolamine to the mixed solution A, then add toluenesulfonic acid and toluene, and stir and react for 7 hours at 115°C to obtain the mixed solution B;

[0057] 3) After heating the rosin to 110°C, stir for 5 hours;

[0058]4) Add the heat-treated rosin in step 3) to the mixed solution B, and then stir and react for 8 hours at a temperature of 110° C. to obtain the mixed solution C;

[0059] 5) Distill the mixed solution C under reduced pressure to obtain the air-entraining agent used in this application.

preparation example 3

[0061] The air-entraining agent of preparation example 3, its each raw material and the amount of each raw material are as shown in table 1, and its preparation step is:

[0062] 1) Add diethanolamine to DMF, stir evenly, then add maleic anhydride with the same molar weight as diethanolamine, and stir for 3 hours at 30°C to obtain a mixed solution A;

[0063] 2) Add triethanolamine to the mixed solution A, then add toluenesulfonic acid and toluene, and stir and react for 6 hours at 120°C to obtain the mixed solution B;

[0064] 3) After heating the rosin to 120°C, stir for 4 hours;

[0065] 4) Add the heat-treated rosin in step 3) to the mixed solution B, and then stir and react for 7 hours at a temperature of 120° C. to obtain the mixed solution C;

[0066] 5) Distill the mixed solution C under reduced pressure to obtain the air-entraining agent used in this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com