Treatment method of landfill leachate concentrate

A technology for landfill leachate and a treatment method, which is applied in the field of landfill leachate concentrate treatment, can solve the problems of inability to achieve standard discharge, volatile organic matter, and high energy consumption, and achieves the effect of good environmental protection benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

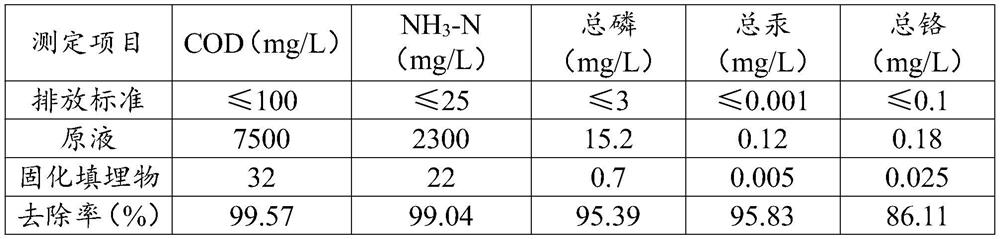

Embodiment 1

[0024] The treatment method of the landfill leachate concentrate specifically comprises the following steps:

[0025] (1) Add 0.5kg of xanthate to every 100kg of landfill leachate concentrate, stir at a speed of 250r / min for 8min, let stand for 1.5h, and filter to obtain concentrate I;

[0026] (2) Add 1.5kg of sodium sulfate and 1.5kg of calcium sulfate successively to every 100kg of concentrated solution I, and stir at a speed of 150r / min for 20min to obtain concentrated solution II;

[0027] (3) Add 300kg of slag portland cement to every 100kg of concentrated solution II, stir at a speed of 100r / min for 12min, solidify for 2d, and landfill.

Embodiment 2

[0029] The treatment method of the landfill leachate concentrate specifically comprises the following steps:

[0030] (1) Add 0.4kg of sodium dithiocarbamate to every 100kg of landfill leachate concentrate, stir at a speed of 200r / min for 5min, let stand for 1h, and filter to obtain concentrate Ⅰ;

[0031] (2) Add 1 kg of sodium sulfate and 1 kg of calcium sulfate successively to every 100 kg of concentrated solution I, and stir at a speed of 100 r / min for 15 minutes to obtain concentrated solution II;

[0032] (3) Add 200kg of slag Portland cement to every 100kg of concentrate II, stir at 80r / min for 10min, solidify for 1d, and landfill.

Embodiment 3

[0034] The treatment method of the landfill leachate concentrate specifically comprises the following steps:

[0035] (1) Add 0.6 kg of sodium dimethyldithiocarbamate to every 100 kg of landfill leachate concentrate, stir at a speed of 300 r / min for 10 min, let stand for 2 hours, and filter to obtain concentrate I;

[0036] (2) Add 2kg of sodium sulfate and 2kg of calcium sulfate successively to every 100kg of concentrated solution I, and stir at a speed of 200r / min for 30min to obtain concentrated solution II;

[0037] (3) Add 400kg of fly ash Portland cement to every 100kg of concentrate II, stir at 120r / min for 15min, solidify for 2d, and landfill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com