High-strength strain clamp and processing technology thereof

A tension clamp, processing technology, applied in coating, surface pretreatment, devices for coating liquids on the surface, etc. Good properties, improved strength, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

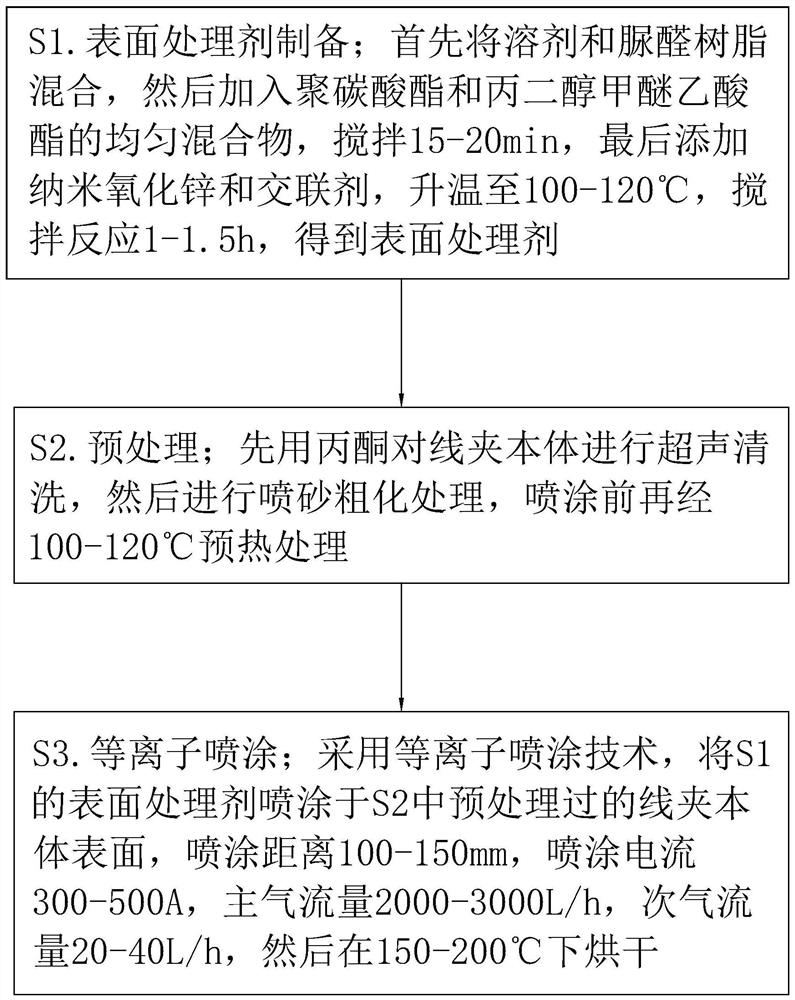

[0043] The invention discloses a high-strength tension-resistant wire clamp and its processing technology. figure 1 , the processing technology includes the following steps:

[0044] S1. Preparation of surface treatment agent; firstly mix the solvent and urea-formaldehyde resin, then add a homogeneous mixture of polycarbonate and propylene glycol methyl ether acetate, stir for 15 minutes, finally add nano-zinc oxide and crosslinking agent, heat up to 100°C, and stir Reaction 1h, obtains surface treatment agent;

[0045] S2. Pretreatment: firstly use acetone to ultrasonically clean the clamp body, then perform sandblasting and roughening treatment, and then preheat at 100°C before spraying;

[0046] S3. Plasma spraying: using plasma spraying technology, spray the surface treatment agent of S1 on the surface of the clamp body pretreated in S2, the spraying distance is 100mm, the spraying current is 300A, the main air flow rate is 2000L / h, and the secondary air flow rate is 20L / ...

Embodiment 2

[0049] The invention discloses a high-strength tension-resistant wire clamp and its processing technology. figure 1 , the processing technology includes the following steps:

[0050] S1. Preparation of surface treatment agent; firstly mix the solvent and urea-formaldehyde resin, then add the homogeneous mixture of polycarbonate and propylene glycol methyl ether acetate, stir for 20min, finally add nano-zinc oxide and crosslinking agent, heat up to 120°C, stir React for 1.5h to obtain the surface treatment agent;

[0051]S2. Pretreatment: firstly use acetone to ultrasonically clean the clamp body, then perform sandblasting and roughening treatment, and then preheat at 120°C before spraying;

[0052] S3. Plasma spraying: using plasma spraying technology, spray the surface treatment agent of S1 on the surface of the clamp body pretreated in S2, the spraying distance is 150mm, the spraying current is 500A, the main air flow rate is 3000L / h, and the secondary air flow rate is 40L / ...

Embodiment 3

[0055] The invention discloses a high-strength tension-resistant wire clamp and its processing technology. figure 1 , the processing technology includes the following steps:

[0056] S1. Preparation of surface treatment agent; firstly mix the solvent and urea-formaldehyde resin, then add a homogeneous mixture of polycarbonate and propylene glycol methyl ether acetate, stir for 18 minutes, finally add nano-zinc oxide and cross-linking agent, heat up to 110°C, and stir React for 1.5h to obtain the surface treatment agent;

[0057] S2. Pretreatment: firstly use acetone to ultrasonically clean the clamp body, then perform sandblasting and roughening treatment, and then preheat at 110°C before spraying;

[0058] S3. Plasma spraying: using plasma spraying technology, spray the surface treatment agent of S1 on the surface of the clamp body pretreated in S2, the spraying distance is 120mm, the spraying current is 450A, the main air flow rate is 2600L / h, and the secondary air flow rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com