Powder-bonded 3D printing soft rock alkali-activated material and application method thereof

A 3D printing and powder bonding technology, which is applied in the analysis of materials, additive processing, instruments, etc., can solve the problems of not being able to print the binder jet, difficulty in uniform distribution, and high viscosity of the activator, so as to achieve the reduction of printing accuracy and laying Dense, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

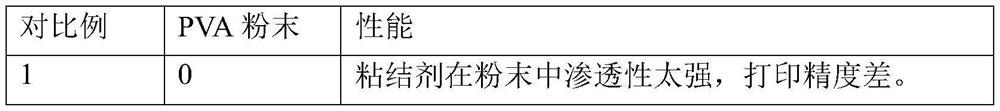

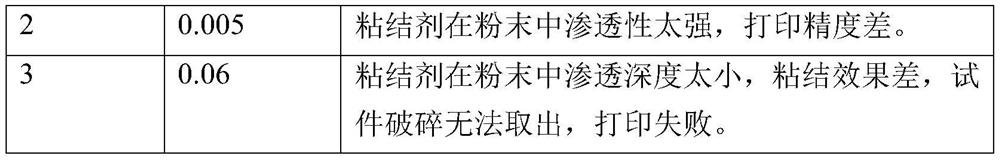

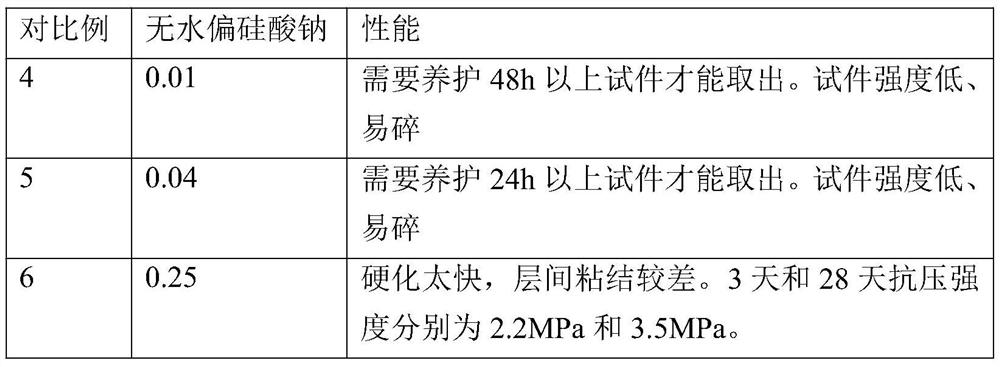

Examples

Embodiment 1

[0045] The powder bonded 3D printing soft rock alkali excitation material used in the simulation of the mechanical properties of soft rock in this embodiment is composed of:

[0046] 1.0 part of fly ash, 1.0 part of blast furnace slag powder, 0.05 part of silica fume, 0.5 part of quartz powder, 0.15 part of limestone powder, 0.01 part of clay, 0.15 part of alkali activator powder, 0.03 part of PVA powder, 0.003 part of glycerin, 0.003 part of cooling liquid, 0.3 parts of water.

[0047] The loss on ignition of the fly ash is 8.2%, the moisture content is 0.08%, the fineness is 26.5% after sieving through a 45 μm square hole sieve, and the maximum particle size is 0.1 mm.

[0048] The alkali activator is anhydrous sodium metasilicate powder.

[0049] The PVA powder is 300-400 mesh, and the density is 1.19-1.31g / cm 3 .

[0050] The average particle size of the quartz powder is 350 μm, the maximum particle size is 0.6 mm, and the specific surface area is 0.155 m 2 / g.

[005...

Embodiment 2

[0064] The powder bonded 3D printing soft rock alkali excitation material used for the simulation of soft rock mechanical properties of the present invention is composed of:

[0065] 0.8 part of fly ash, 1.0 part of blast furnace slag powder, 0.07 part of silica fume, 0.6 part of quartz powder, 0.10 part of limestone powder, 0.005 part of clay, 0.12 part of alkali activator powder, 0.02 part of PVA powder, 0.002 part of glycerin, 0.004 part of cooling liquid, 0.35 parts of water.

[0066] The loss on ignition of the fly ash is 8.2%, the moisture content is 0.08%, the fineness is 26.5% after sieving through a 45 μm square hole sieve, and the maximum particle size is 0.1 mm.

[0067] The density of the blast furnace slag powder is 2.8g / cm 3 , the specific surface area is 350m 2 / kg, the moisture content is 0.3%, and the maximum particle size is 85μm.

[0068] The alkali activator powder is 0.07 part of sodium silicate powder and 0.05 part of sodium hydroxide powder, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com