A test method for composite modified concrete and its interfacial transition zone

A technology of interfacial transition zone, composite modification, used in the application of stable tension/pressure to test material strength, measurement device, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0040]The raw material was measured according to the following coordination ratio: 100 parts of cement, 250 stones, 39 sand, 39 of the water, 30 of the fly ash, 1.2 parts of nanosoxide, and 0.5 high-efficiency water reducer.

[0041]The preparation process of the above modified concrete is as follows:

[0042](1) First put the nano silica and all water into the ultrasonic system, the ultrasonic system has a working frequency of 40 kHz, and the ultrasonic power supply is 50 W to prepare the nano-modified dispersion;

[0043](2) The cement, fly ash, silica gray, stone, sand, and high-efficiency water reducer are then stirred in a concrete mixer, so that all raw materials can be uniformly mixed;

[0044](3) Then, then poured the nano dispersion into the stirrer for 6 minutes until a uniform concrete mixture was obtained;

[0045](3) Put the concrete mixture into the mold, and rearrange the mold after one day, and maintenance under the standard conditions.

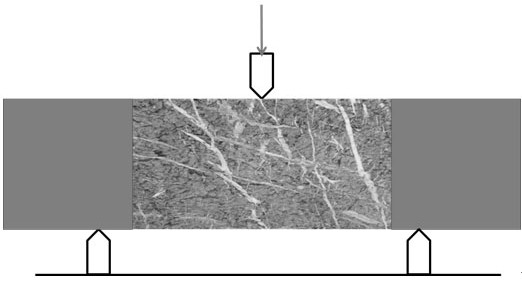

[0046]The method of transition bonding strengt...

Embodiment example 2

[0051]The raw material was measured according to the following coordination ratio: 100 parts of cement, 250 pieces of stone, 39 sanding, 39 pieces of water, 5 serviles, 1.5 nano silica, and 1.5 high-efficiency water reducer.

[0052]The preparation process of the above modified concrete is as follows:

[0053](1) First put the nano silica and all water into the ultrasonic system, the ultrasonic system has a working frequency of 40 kHz, and the ultrasonic power supply is 50 W to prepare the nano-modified dispersion;

[0054](2) The cement, fly ash, silica gray, stone, sand, high-efficiency water reducer are placed in a concrete mixer for 4 min, so that all raw materials can be uniformly mixed;

[0055](3) Then pour the nano-modified dispersion into the stirrer for 6 minutes until a uniform concrete mixture is obtained;

[0056](4) Put the concrete mixture into the mold, rewind the mold after one day, and maintenance under standard conditions.

[0057]Method of transition bonding strength test of concr...

Embodiment example 3

[0059]The raw material was measured according to the following ratio: 100 parts of cement, 250 stones, 39 sand, 39 pieces of water, 3 of the fly ash, 9 pieces of silica, and 1.8 parts of nano-titanium dioxide and 1 high-efficiency water reducer.

[0060]The preparation process of the above modified concrete is as follows:

[0061](1) First, the nano titanium dioxide and all water are placed in the ultrasound system, and the operating frequency of the ultrasound system is 40 kHz, the ultrasonic power supply is 50 W, to prepare the nano modified agent dispersion;

[0062](2) The cement, fly ash, silica gray, stone, sand, high-efficiency water reducer are placed in a concrete mixer for 4 min, so that all raw materials can be uniformly mixed;

[0063](3) Then pour the nano-modified dispersion into the stirrer for 6 minutes until a uniform concrete mixture is obtained;

[0064](4) Put the concrete mixture into the mold, rewind the mold after one day, and maintenance under standard conditions.

[0065]Meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com