Bio-derived porous carbon prepared by micro-explosion and application of bio-derived porous carbon in supercapacitor

A technology of supercapacitor and explosion method, which is applied in the field of supercapacitor application research, can solve problems such as limiting the voltage window of devices and limiting the energy density of supercapacitors, and achieves the effect of low cost, simple and efficient preparation method, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

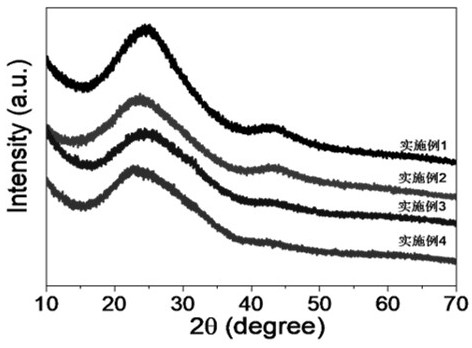

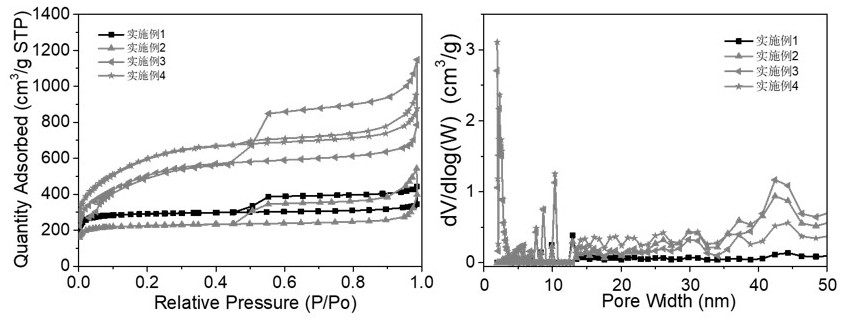

Embodiment 1

[0022] First, add 2g of carrageenan into 50ml of deionized water, stir until completely dissolved, and stir into a clear solution in a water bath at 80°C. It was then cooled to room temperature to form a gel, which was placed in a -40°C freezer for 12 hours. Then place it in a vacuum freeze dryer for freeze-drying to obtain carrageenan aerogel. Afterwards, the obtained carrageenan airgel was placed in a tube furnace and annealed at 700 °C for 60 min under an argon atmosphere with a heating rate of 2 °C / min. The obtained black sample was washed 3 times with deionized water and dried in a vacuum oven at 80 °C for 12 hours to obtain the final sample.

Embodiment 2

[0024] On the basis of Example 1, 0.1 g of sodium citrate was added to 2 g of carrageenan solution to fully dissolve completely. Subsequent processing is the same as in Example 1.

Embodiment 3

[0026] On the basis of Example 1, 0.1 g of sodium nitrate was added into 2 g of carrageenan solution to fully dissolve completely. Subsequent processing is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com