Processing device for semiconductor graphite wafer and processing method thereof

A processing device and semiconductor technology, applied in the direction of fine working device, stone processing equipment, semiconductor/solid-state device manufacturing, etc., can solve the problems of increasing operator workload, large wafer cutting error, and reducing product productivity, etc. Improve the success rate, facilitate cutting, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

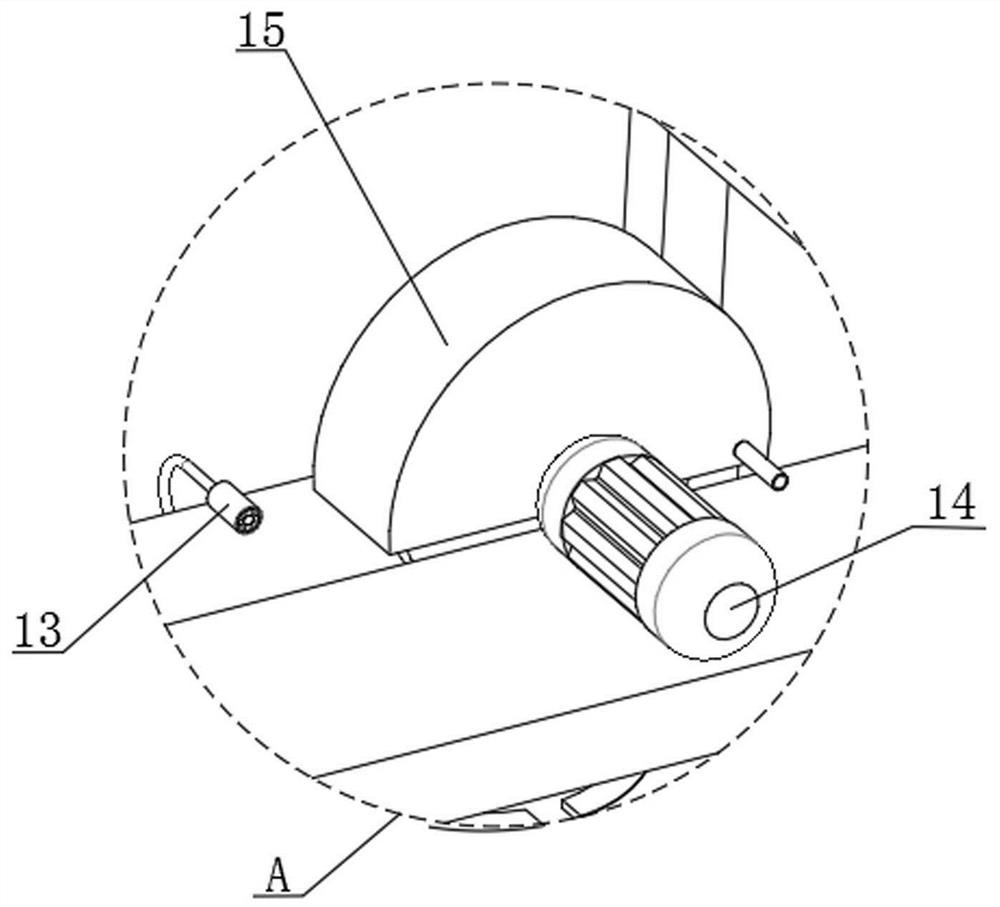

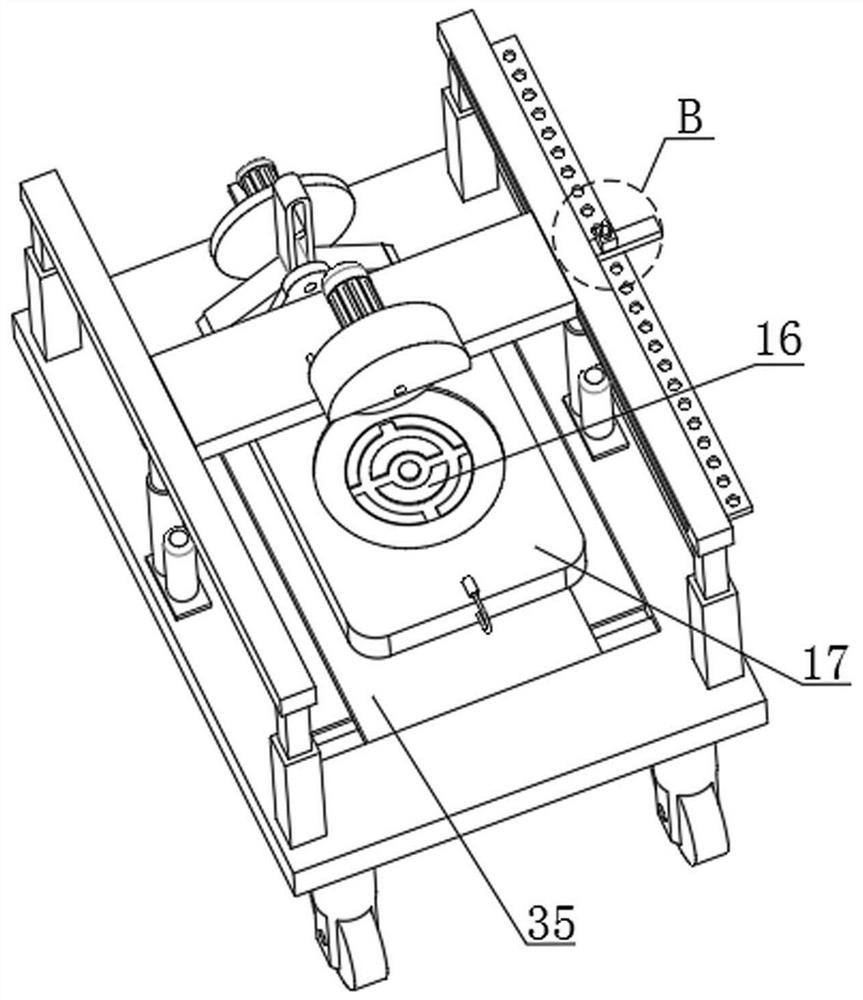

[0033] Embodiment 1: see Figure 1-8 , a processing device for semiconductor graphite wafers, including a base 1, the base 1 is a rectangular plate placed horizontally, a rectangular groove is opened in the middle of the top surface of the base 1, and the bottom surface of the rectangular groove is symmetrical at both ends longitudinally A first T-shaped slot is provided, and a first T-shaped slider is slidably connected in each of the first T-shaped slots, and the top surface of each first T-shaped slider is fixed on the movable plate 35. On the bottom surface, it is convenient for the movable plate 35 to slide in the rectangular groove; the top side edge of the movable plate 35 is provided with an adjustment assembly, which is convenient to adjust the front and rear movement of the movable plate 35; the middle part of the top surface of the movable plate 35 is provided with The rotating assembly, the top of the fixed shaft 38 in the rotating assembly is affixed with the work...

Embodiment 2

[0040] Embodiment 2: refer to Figure 8 , in the present embodiment, the present invention also proposes the processing method for the processing device of semiconductor graphite wafer, comprises the following steps:

[0041] Step 1, the first motor 22, the second motor 28, the third motor 14, and the fan are respectively electrically connected to the external power supply through wires, and the water guide pipe is connected to the external water source, and then the circular wafer is put into the card slot, and the negative pressure Groove 16 fixes the circular wafer;

[0042] Step 2, by controlling the first electric push rod 2 and the second electric push rod 9 to drive the second support rod 4 and the fourth support rod 10 to move up and down respectively, the second support rod 4 and the fourth support rod 10 drive the support plate 8 up and down Movement, the support plate 8 drives the cutting assembly to move up and down, and then pushes the support plate 8 to move the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com