Self-moving heat removal type smoke exhaust pipeline for calcining furnace

A flue gas duct, self-moving technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of increasing the cleaning frequency of flue gas ducts, pollute the environment, air pollution, etc., reduce the adhesion rate of smoke and dust, and achieve high cooling efficiency. , the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

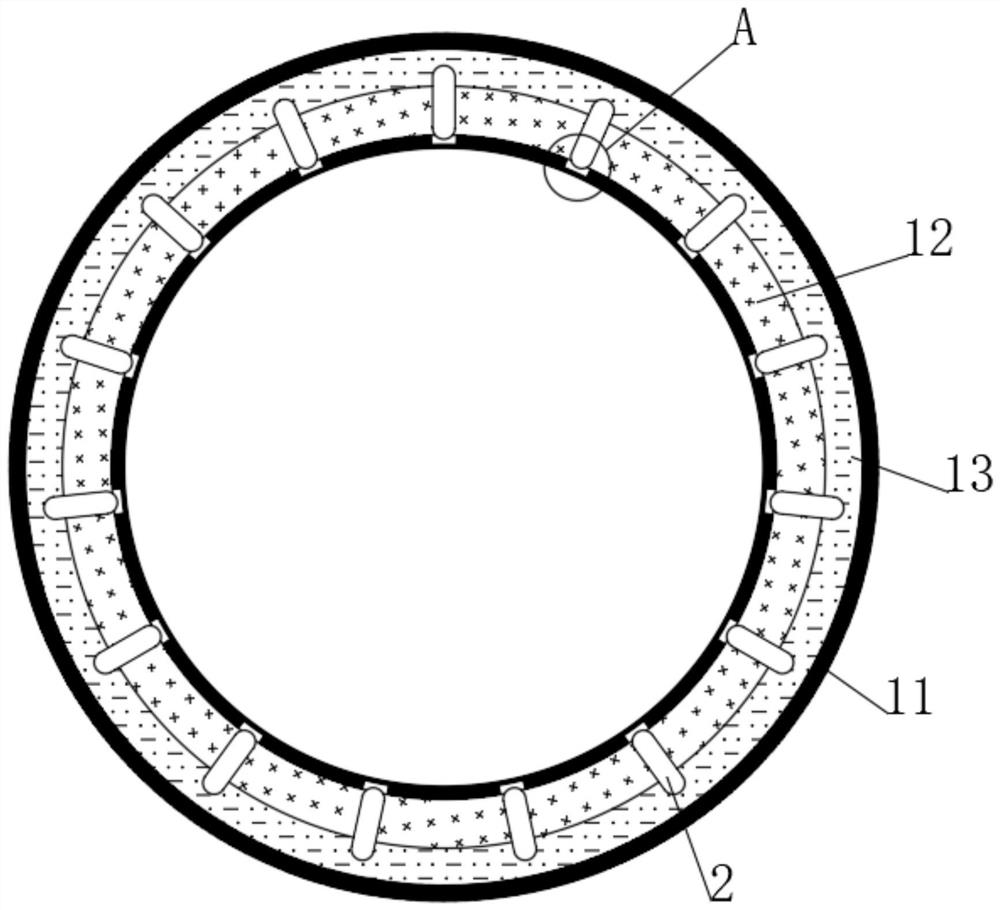

[0038] see figure 1 , a smoke exhaust pipe for a self-moving heat-removing type calciner, comprising a pipe body 11, an inner heat-conducting layer 12 is inlaid inside the pipe body 11, a heat-removing cavity 13 is dug inside the pipe body 11, and the outer end of the pipe body 11 is fixedly connected with a The water inlet pipe and the water outlet pipe, and the water inlet pipe and the water outlet pipe are all communicated with the heat removal chamber 13, and the condensed water circulation can be carried out in the heat removal chamber 13 through the water inlet pipe and the water outlet pipe. The heat removal chamber 13 is located outside the inner heat conducting layer 12, A plurality of uniformly distributed thermal reciprocating rods 2 are movably embedded in the inner heat conducting layer 12 .

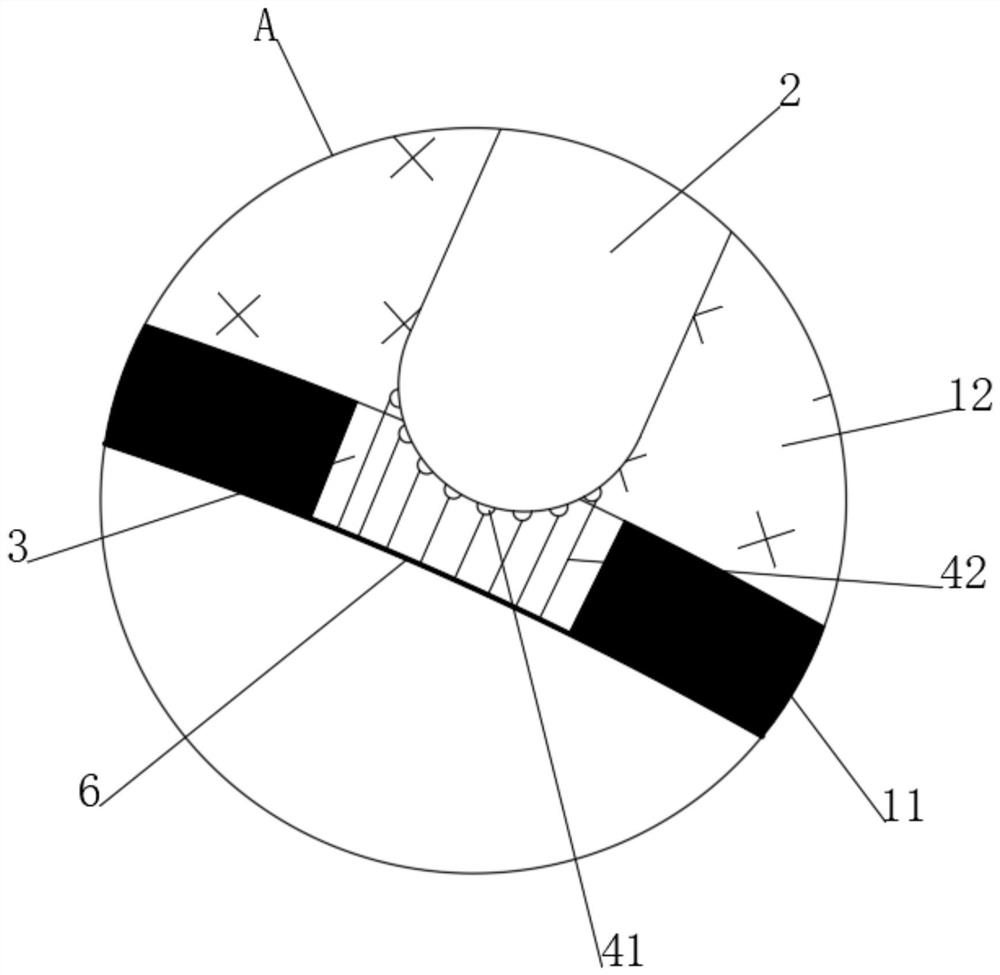

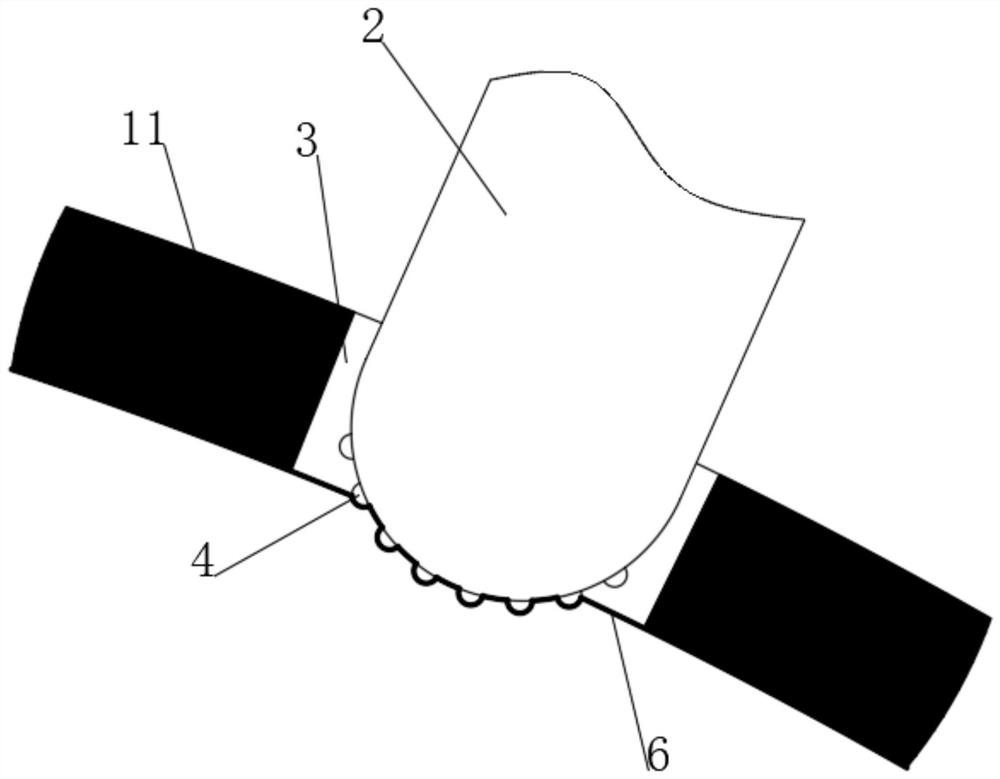

[0039] see figure 2 , the inner wall of 1 has a plurality of heat exchange holes 3 corresponding to the heat reciprocating rod 2, one end of the heat reciprocating rod 2 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com