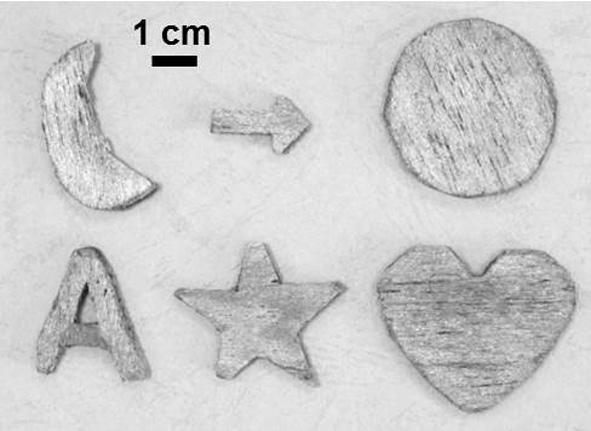

A kind of multifunctional metallized wood material and its preparation method and application

A wood material and metallization technology, applied in impregnated wood, wood impregnation, wood processing equipment, etc., can solve problems such as difficult synthesis of metallized wood, and achieve the effect of rich raw material sources, good porous structure, and excellent compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the multifunctional metallized wood material of the present embodiment comprises the following steps:

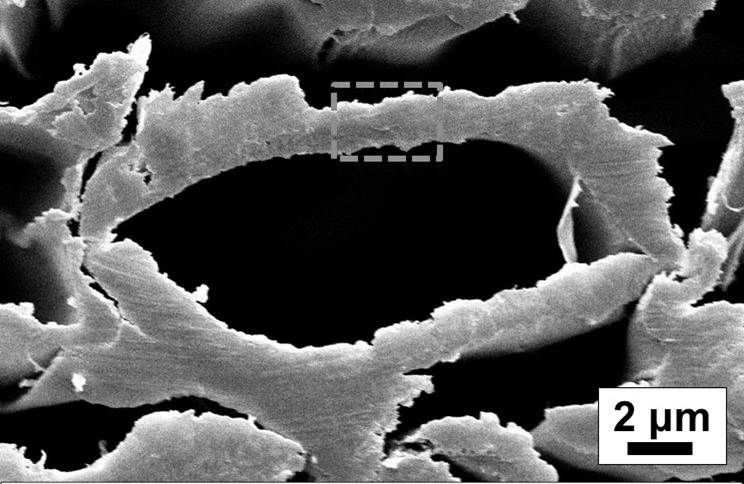

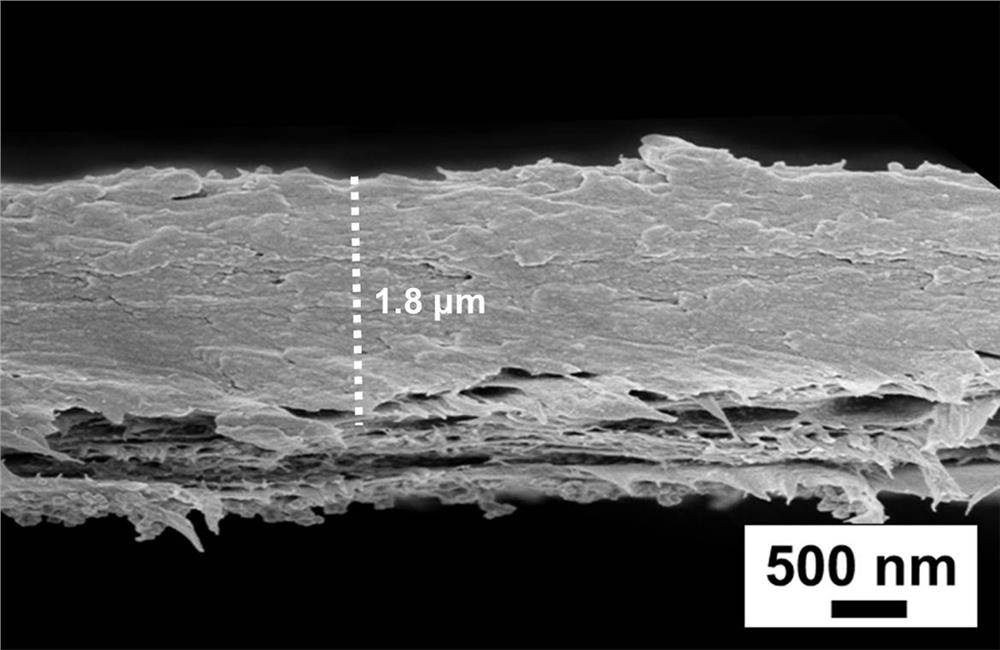

[0029] (1) Cut about 20g of basswood into pieces, soak in 500mL boiling mixed aqueous solution containing 6g of sodium hydroxide and 18g of sodium sulfite, take it out after reacting for 10h, and then soak it in boiling sub Sodium chlorate solution, until the wood turns white, fully rinse the wood with deionized water after the reaction, and freeze-dry to obtain porous wood rich in cellulose;

[0030] (2) Weigh about 5g of porous wood, soak it in 200mL deionized water with a pH of about 10, then add about 2mmol of sodium hypochlorite, react for 2 hours, add 0.5mol / L hydrochloric acid until the pH of the solution is neutral to terminate the reaction, and then use Soak the wood in 0.5mol / L hydrochloric acid, wash the wood several times with deionized water, and freeze-dry to obtain oxidized porous wood;

[0031] (3) Weigh about 2 g of oxidized...

Embodiment 2

[0035] The preparation method of the multifunctional metallized wood material of the present embodiment comprises the following steps:

[0036] (1) Cut about 10g of basswood into pieces, soak it in 300mL of boiling mixed aqueous solution containing 10g of sodium hydroxide and 15g of sodium sulfite, take it out after reacting for 12 hours, and then soak it in boiling 0.5% sodium sulfite Sodium chlorate solution, until the wood turns white, fully rinse the wood with deionized water after the reaction, and freeze-dry to obtain porous wood rich in cellulose;

[0037] (2) Weigh about 5g of porous wood, soak it in 200mL of deionized water with a pH of about 10, then add about 3mmol of sodium hypochlorite, react for 3 hours, add 0.5mol / L hydrochloric acid until the pH of the solution is neutral to terminate the reaction, and then use Soak wood in 0.5mol / L hydrochloric acid solution, wash wood several times with deionized water, and obtain oxidized porous wood after freeze-drying;

...

Embodiment 3

[0041] The preparation method of the multifunctional metallized wood material of the present embodiment comprises the following steps:

[0042] (1) Cut about 10g of basswood into pieces, soak in 300mL of boiling mixed aqueous solution containing 10g of sodium hydroxide and 15g of sodium sulfite, react for about 12 hours, take it out, and then soak in boiling water with a mass fraction of about 0.5% In the sodium chlorite solution, until the wood turns white, the wood is fully rinsed with deionized water after the reaction, and after freeze-drying, the porous wood rich in cellulose is obtained;

[0043] (2) Weigh about 3g of porous wood, soak it in 100mL deionized water with a pH of about 10, then add about 0.6mmol of sodium hypochlorite, react for 5 hours, add 0.2mol / L hydrochloric acid until the pH of the solution is neutral to terminate the reaction, then Soak the wood with 0.2mol / L hydrochloric acid solution, wash the wood several times with deionized water, and freeze-dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com