Preparation method for activated carbon/carbon nano tube mixed electrode material, and product thereof and application

A technology of carbon nanotubes and mixed electrodes, which is applied in the manufacture of hybrid/electric double-layer capacitors, carbon-silicon compound conductors, cables/conductors, etc., can solve the limitations of supercapacitors such as small-scale research and testing, complex equipment used, and high preparation costs. problems, to achieve the effect of low preparation cost, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

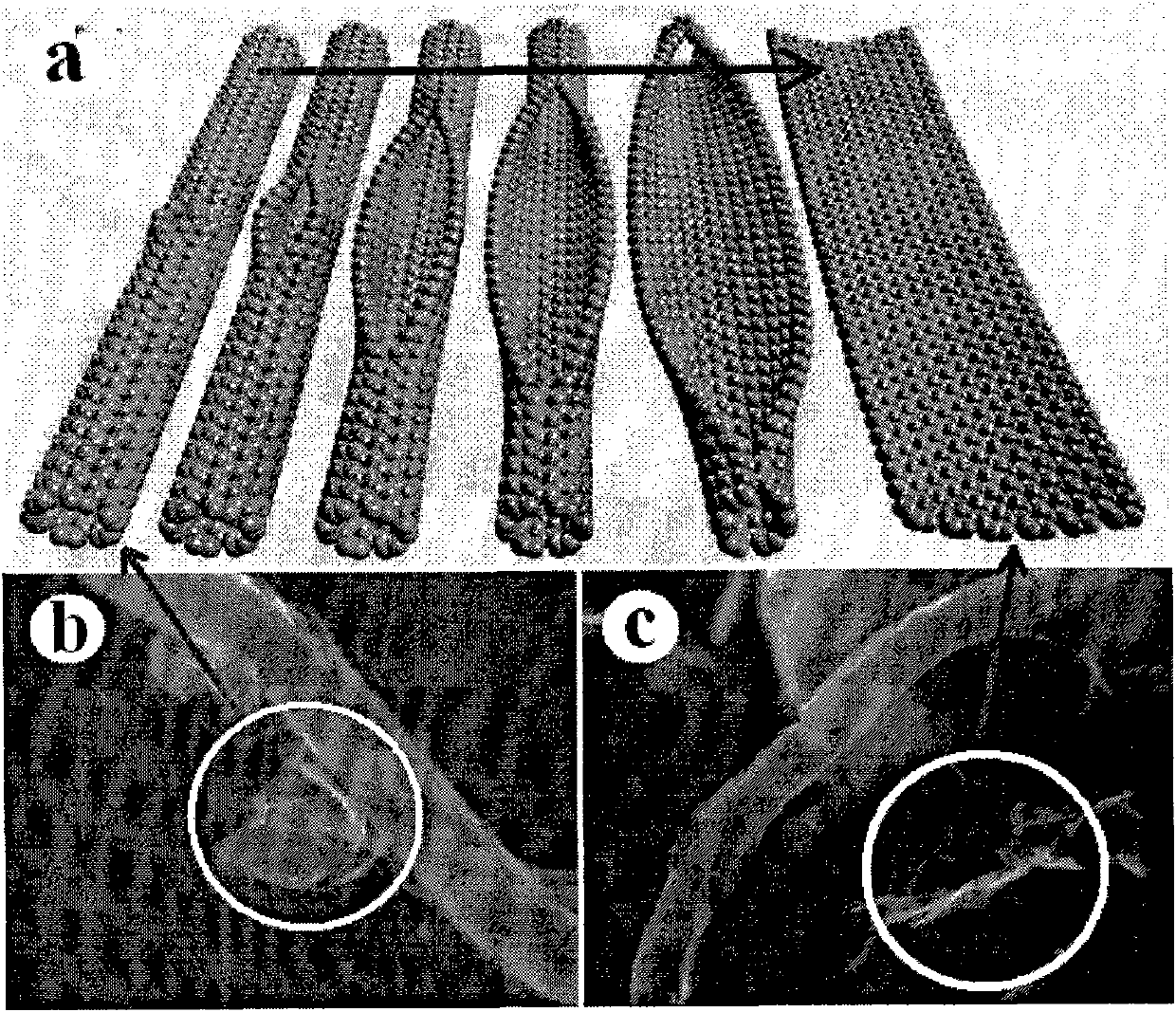

Image

Examples

Embodiment 1

[0040] 1) Accurately weigh 5.00g of mesophase carbon microspheres and 25.00g of KOH, add appropriate amount of deionized water and mix into a slurry;

[0041]2) the above-mentioned slurry is placed in the first stainless steel container with a movable lid, and the lid is covered; then it is put into another second stainless steel container with a larger volume and the same with a movable lid, and the petroleum coke powder (particle size 60μm) filled to full, cover the lid;

[0042] 3) Put the above-mentioned second stainless steel container covered with a lid in a muffle furnace, heat it up to 900°C at a heating rate of 2°C / min, keep it warm for 2 hours, and cool it to normal temperature with the furnace, and take out the product with a volume concentration of 5% The basic compounds and metal impurities brought in during the reaction were washed away with hydrochloric acid, then washed with deionized water until neutral, and dried at 80°C for 24 hours to obtain 2.39g of AMCMB / ...

Embodiment 2

[0047] 1) Accurately weigh 5.00g of mesophase carbon microspheres and 50.00g of KOH, add appropriate amount of deionized water and mix into a slurry;

[0048] 2) the above-mentioned slurry is placed in the first stainless steel container with a movable lid, and the lid is covered; then it is put into another second stainless steel container with a larger volume and the same with a movable lid, and the petroleum coke powder (particle size 80μm) filled to full, cover the lid;

[0049] 3) Place the above-mentioned second stainless steel container with the lid on in a muffle furnace, heat it to 1100°C at a heating rate of 5°C / min, keep it warm for 3h, and cool to room temperature with the furnace, and take out the product with a volume concentration of 10% The basic compounds and metal impurities brought in during the reaction were washed away with hydrochloric acid, then washed with deionized water until neutral, and dried at 60° C. for 30 h to obtain 1.73 g of AMCMB / CNT mixed el...

Embodiment 3

[0053] 1) Accurately weigh 5.00g of mesophase carbon microspheres and 50.00g of KOH, add appropriate amount of deionized water and mix into a slurry;

[0054] 2) the above-mentioned slurry is placed in the first stainless steel container with a movable lid, and the lid is covered; then it is put into another second stainless steel container with a larger volume and the same with a movable lid, and the petroleum coke powder (particle size 100μm) filled to full, cover the lid;

[0055] 3) Put the above-mentioned second stainless steel container with the lid on in a muffle furnace, heat it up to 1000°C at a heating rate of 4°C / min, keep it warm for 5h, and cool it to room temperature with the furnace, and take out the product with a volume concentration of 5%. 2.02 g of AMCMB / CNT mixture was obtained after washing with deionized water to neutrality, and drying at 90°C for 20 hours;

[0056] The specific surface area of the activated carbon / carbon nanotube hybrid electrode mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com