Carbon-coated vanadium pentoxide positive electrode material as well as preparation method thereof and application of carbon-coated vanadium pentoxide positive electrode material in lithium battery

A carbon-coated technology of vanadium pentoxide and vanadium pentoxide, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of small lithium ion diffusion coefficient, poor cycle stability, unstable structure, etc. Electrical conductivity and structural stability, improving electrical conductivity, the effect of increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

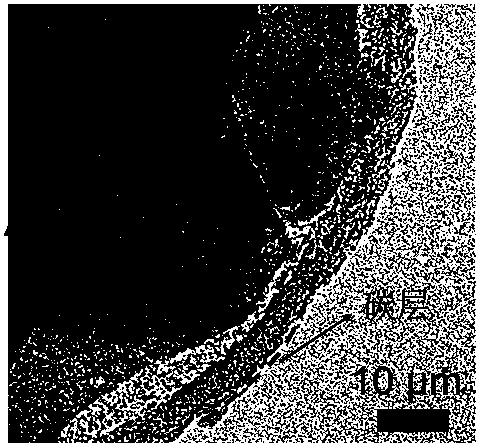

[0023] A carbon-coated vanadium pentoxide positive electrode material, the positive electrode material has a sandwich structure, the outer cladding layer of the sandwich structure is a nitrogen-doped carbon material, and the inner sandwich material of the sandwich structure is graphene foam and Vanadium pentoxide, the vanadium pentoxide grows on the surface of the graphene foam.

[0024] Further, the carbon content of the positive electrode material is 10-50 wt%, the content of nitrogen element is 0.01-5 wt%, the content of vanadium element is 5-50 wt%, and the rest is oxygen element content.

[0025] The invention provides a method for preparing a carbon-coated vanadium pentoxide positive electrode material. VS is grown on a conductive three-dimensional porous graphene foam substrate. 2 precursor, the active V 2 o 5 , and then coat the dopamine in the active substance V 2 o 5 surface, through further high-temperature carbonization, carbon-coated V 2 o 5 Cathode material...

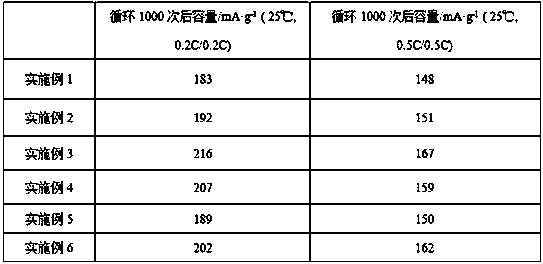

Embodiment 1

[0032] (1) Put 2 mg of three-dimensional porous graphene foam substrate in a mixed solution of thioacetamide with a concentration of 20 mg / ml and ammonium metavanadate with a concentration of 30 mg / ml, and conduct a hydrothermal reaction at 180°C for 24 h to obtain Graphene foam grown with vanadium disulfide having a three-dimensional nanosheet structure;

[0033] (2) In growth there is VS 2 The graphene foam of the nanosheet is placed in a tube furnace, annealed in air at 100° C. for 5 h to obtain a graphene foam growing with vanadium pentoxide, and the vanadium pentoxide has a three-dimensional nanosheet structure;

[0034] (3) Grind the graphene foam grown with vanadium pentoxide into powder particles with a particle size of 5-50 μm, put them in a 1 mg / ml dopamine hydrochloride-Tris mixed solution, and self-polymerize at 10°C for 48 h Film-forming polydopamine, loaded at V 2 o 5 On the surface, the thickness of the polydopamine is 5-10 μm;

[0035] (4) Centrifuge the po...

Embodiment 2

[0038] (1) Put 20 mg of three-dimensional porous graphene foam substrate in a mixed solution with a concentration of 50 mg / ml thioacetamide and a concentration of ammonium metavanadate of 60 mg / ml, and undergo a hydrothermal reaction at 120°C for 12 h to obtain growth organic Graphene foam of vanadium disulfide having a three-dimensional nanosheet structure;

[0039] (2) In growth there is VS 2 The graphene foam of the nanosheet is placed in a tube furnace, and annealed at 400°C for 1 h in the air to obtain a graphene foam with vanadium pentoxide, the vanadium pentoxide has a three-dimensional nanosheet structure;

[0040] (3) Grind the graphene foam with vanadium pentoxide grown on the surface into a powder particle with a particle size of 5-50 μm, then place it in a 5 mg / ml dopamine hydrochloride-Tris mixed solution, and self-polymerize at 35°C 10 h film formation polydopamine, loaded at V 2 o 5 On the surface, the polydopamine has a thickness of 5-10 μm;

[0041] (4) Ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com