Machine tool with built-in motor

A technology for machine tools and lathes, which is applied to the field of machine tools with motors in the middle, can solve the problems affecting the concentricity of the motor spindle, the rotation of the motor spindle, and the long distance, and achieve the effects of convenient limit, improved concentricity, and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

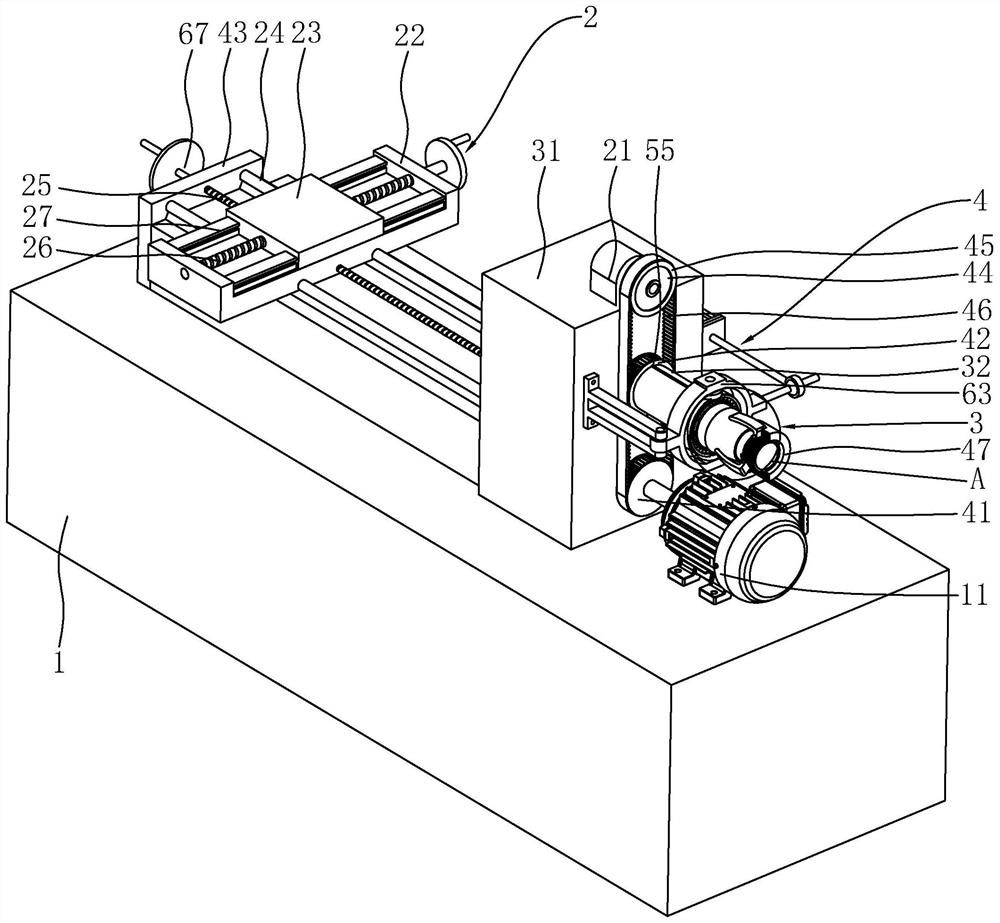

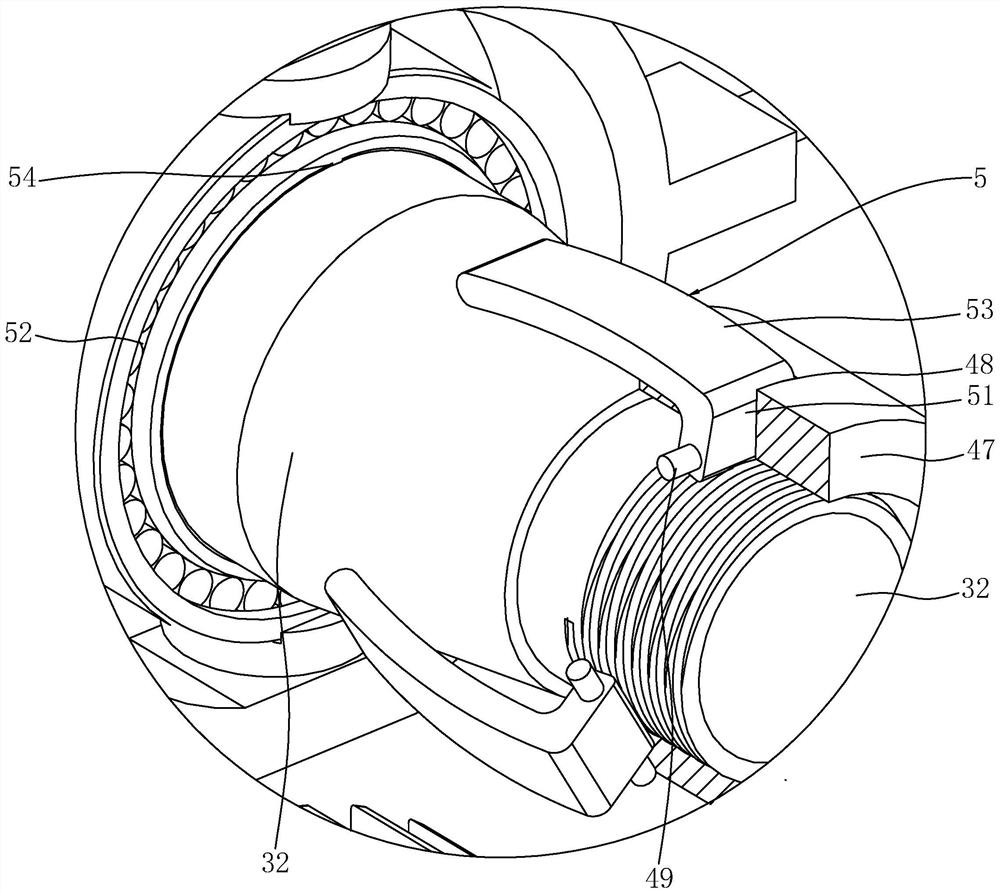

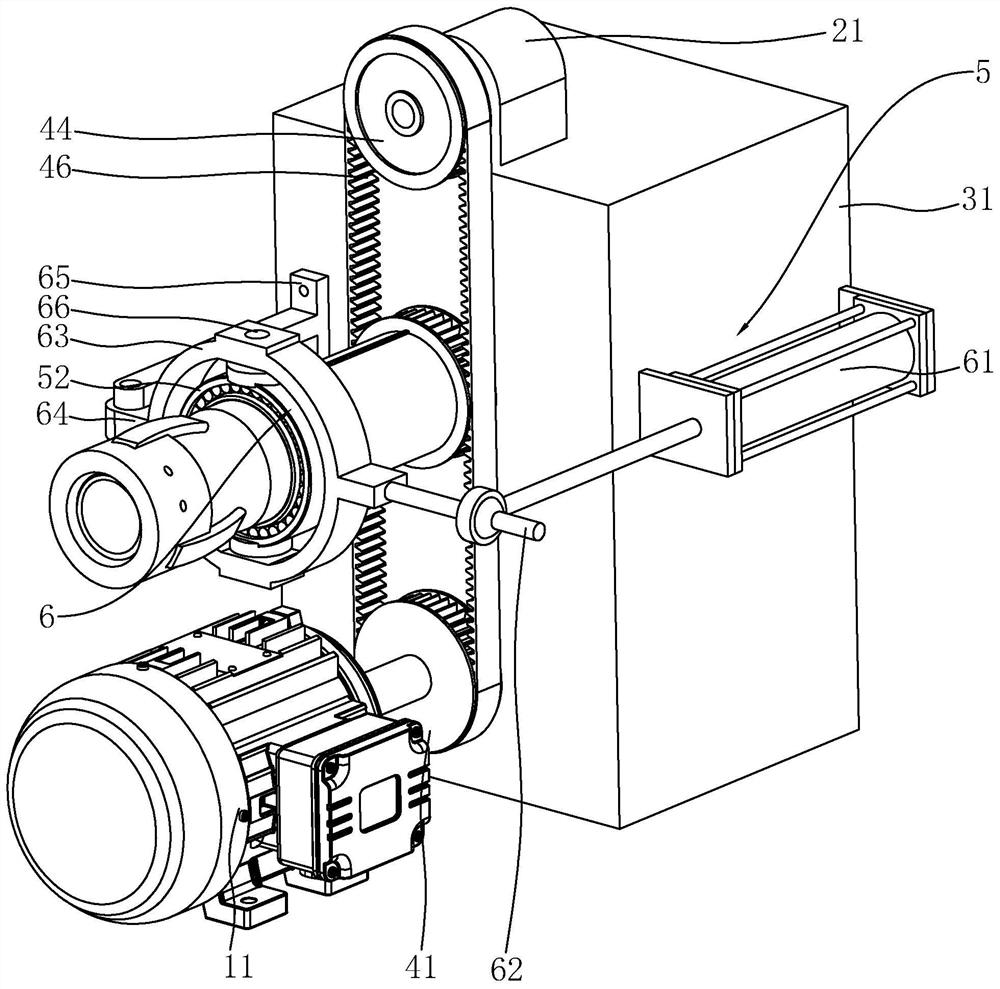

[0032] Embodiment: a kind of machine tool with motor in the middle, such as figure 1 and figure 2 As shown, it includes a base 1 , a motor 11 fixed on the top of the base 1 , and a lathe mechanism 2 and a fixing device 3 arranged on the top of the base 1 . The fixing device 3 includes a fixed platform 31 fixed on the top of the base 1, a fixed tube 32 rotatably mounted on the side of the fixed platform 31 close to the motor 11, and a transmission mechanism arranged between the fixed tube 32 and the motor 11 for driving the fixed tube 32 to rotate 4. The transmission mechanism 4 includes a drive pulley 41 fixed on the output end of the motor 11, a drive pulley 42 fixed on the outer peripheral surface of the fixed pipe 32, a mounting table 21 fixed on the top of the fixed table 31, and a rotation mounted on the side of the mounting table 21 near the fixed pipe 32. An encoder 44, a driven pulley 45 fixed on the outer peripheral surface of the encoder 44, and a toothed belt 46 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com