Combined adsorbent for flue gas desulfurization and denitrification and flue gas desulfurization and denitrification method

A technology of desulfurization and denitrification and adsorbent, which is applied in the field of desulfurization and denitrification technology, can solve the problems of desulfurization agent can not be reused, high removal rate, low loss of adsorbent, etc., achieve no secondary pollution industrial application prospect, pollutant removal The effect of high efficiency and low loss of adsorbent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

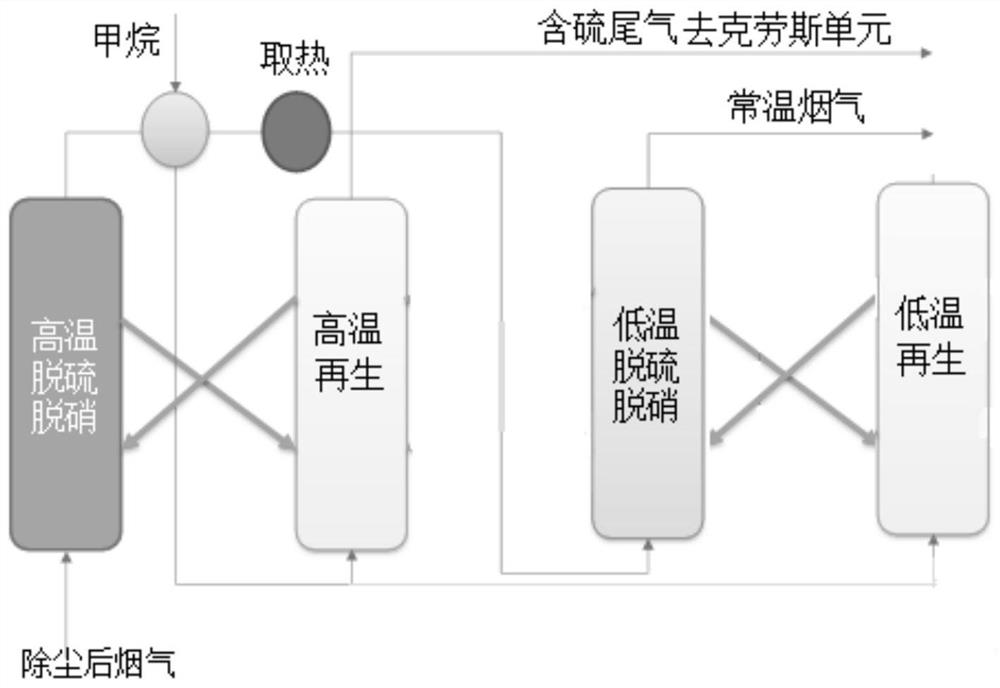

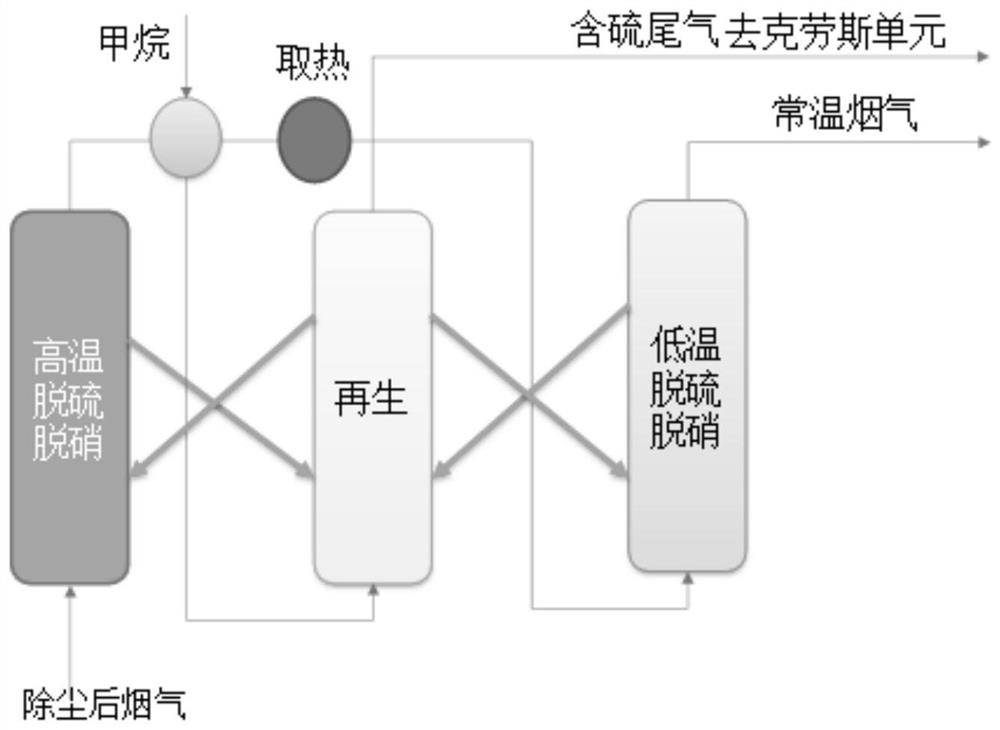

Image

Examples

Embodiment 1

[0042] A combined adsorbent for flue gas desulfurization and denitrification, the combined adsorbent is composed of a low-temperature adsorbent and a high-temperature adsorbent;

[0043] The high-temperature adsorbent includes the following components in parts by weight: 35 parts of mercerized molecular sieve, 15 parts of iron oxide, and 15 parts of binder;

[0044] The low-temperature adsorbent includes the following components in parts by weight: 50 parts of MCM-41 molecular sieve, 5 parts of magnesium oxide, and 15 parts of binder;

[0045] Among them, the specific surface area of mercerized molecular sieve is 280m 2 / g, the specific surface area of MCM-41 molecular sieve is 1156m 2 / g.

[0046] The binder is obtained by mixing alumina and kaolin at a mass ratio of 1:6.

[0047] A method for flue gas desulfurization and denitrification using the above combined adsorbent, comprising the steps of:

[0048] Step 1, flue gas dust removal: transport the flue gas to be tr...

Embodiment 2

[0053] A combined adsorbent for flue gas desulfurization and denitrification, the combined adsorbent is composed of a low-temperature adsorbent and a high-temperature adsorbent;

[0054] The high-temperature adsorbent includes the following components in parts by weight: 40 parts of ZSM-5 molecular sieve, 20 parts of calcium oxide, and 15 parts of bentonite; the low-temperature adsorbent includes the following components in parts by weight: 50 parts of Silica, 20 parts of bentonite;

[0055] Among them, the specific surface area of ZSM-5 molecular sieve is 350m 2 / g, the specific surface area of silicon oxide is 600m 2 / g.

[0056] A method for flue gas desulfurization and denitrification using the above combined adsorbent, comprising the steps of:

[0057] Step 1, flue gas dust removal: transport the flue gas to be treated to the electrostatic precipitator for dust removal pretreatment;

[0058] Step 2. Adsorption desulfurization and denitrification: transport the dus...

Embodiment 3

[0062] A combined adsorbent for flue gas desulfurization and denitrification, the combined adsorbent is composed of a low-temperature adsorbent and a high-temperature adsorbent;

[0063] The high-temperature adsorbent includes the following components in parts by weight: 60 parts of Y-type molecular sieve, 40 parts of nickel oxide, and 25 parts of binder;

[0064] The low-temperature adsorbent includes the following components in parts by weight: 60 parts of activated carbon, 25 parts of binder;

[0065] Among them, the specific surface area of Y-type molecular sieve is 742m 2 / g, the surface area of activated carbon is 890m 2 / g;

[0066] The binder is prepared by mixing alumina and attapulgite at a mass ratio of 1:5.

[0067] A method for flue gas desulfurization and denitrification using the above combined adsorbent, comprising the steps of:

[0068] Step 1, flue gas dust removal: transport the flue gas to be treated to the electrostatic precipitator for dust remova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com