High-temperature-water heat exchange low-temperature-water direct connection heating system

A heating system and high-temperature water technology, applied in the heating field, can solve problems such as unfavorable energy saving and consumption reduction, underutilization of heat energy, etc., and achieve the effect of good energy saving and emission reduction, good social and economic benefits, and lower operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

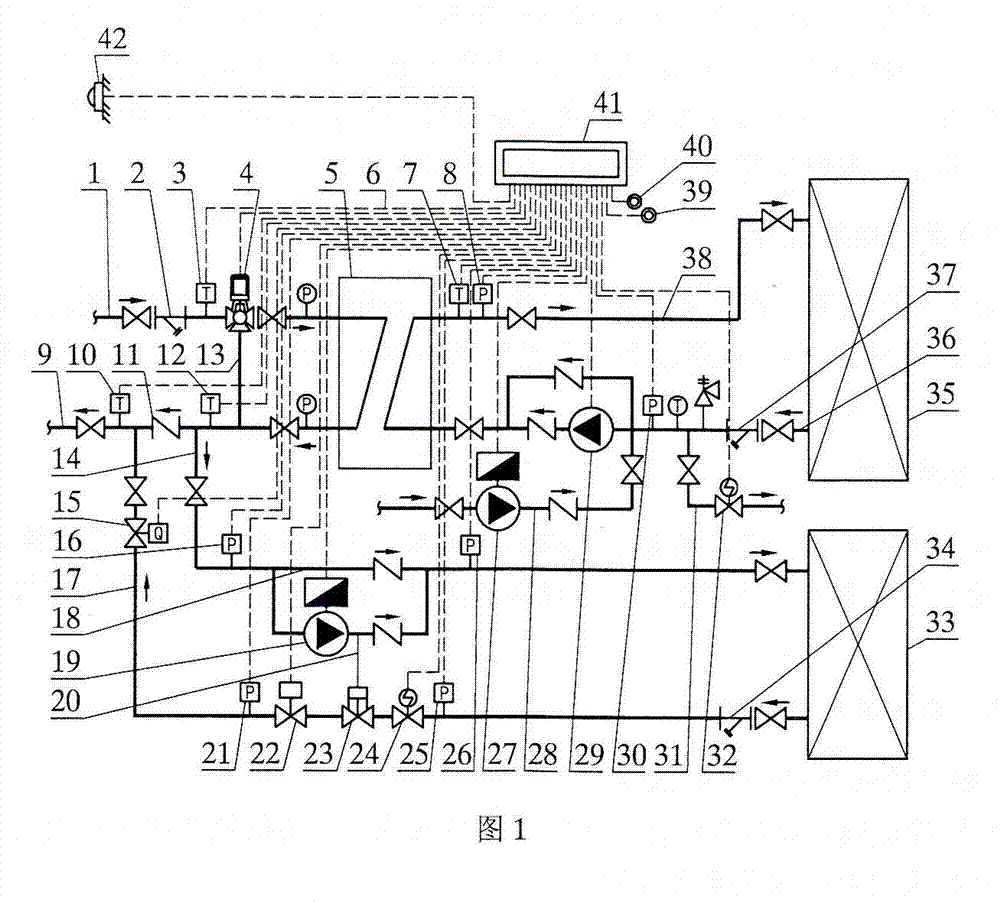

[0011] attached below figure 1 The high-temperature water heat exchange and low-temperature water direct connection heating system of the present invention will be described in detail below.

[0012] as attached figure 1As shown, the high-temperature water heat exchange and low-temperature water direct connection heating system of the present invention is mainly composed of a plate heat exchanger 5, a heating frequency conversion pump 19, a water replenishment frequency conversion pump 27, a circulation pump 29, a direct connection heating area 33, a heat exchange heating area 35, The outdoor temperature sensor 42 and the control cabinet 41 are composed. The primary side interface of the plate heat exchanger 5 is respectively connected with the primary water supply pipe 1 and the primary return water pipe 9. The primary water supply pipe 1 is equipped with a three-way temperature control valve 4, and the primary water supply pipe 1 is in A filter-2 is installed before the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com