Concrete filled steel tube column-H-shaped steel beam-steel support-pi-shaped connecting piece combined type side column bottom joint and manufacturing method

A technology for concrete-filled steel tubular columns and connectors, which can be applied to building components, building types, protective buildings/shelters, etc., and can solve problems such as unfavorable assembly construction, unreasonable stress, and large steel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The invention will be further described below in conjunction with specific embodiments.

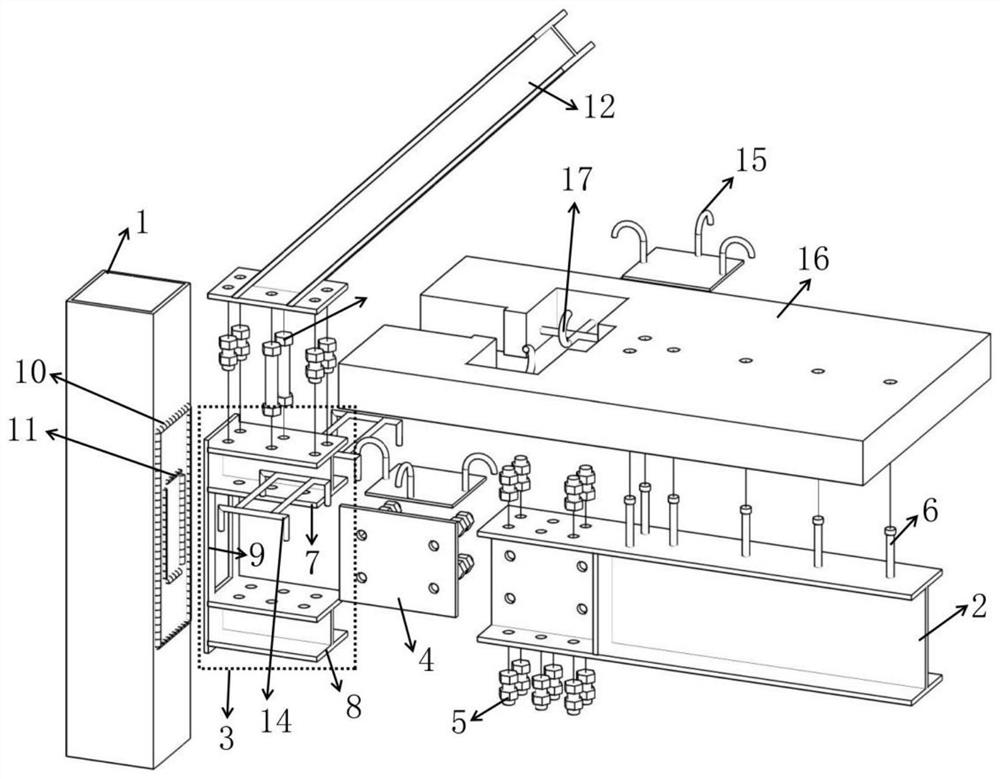

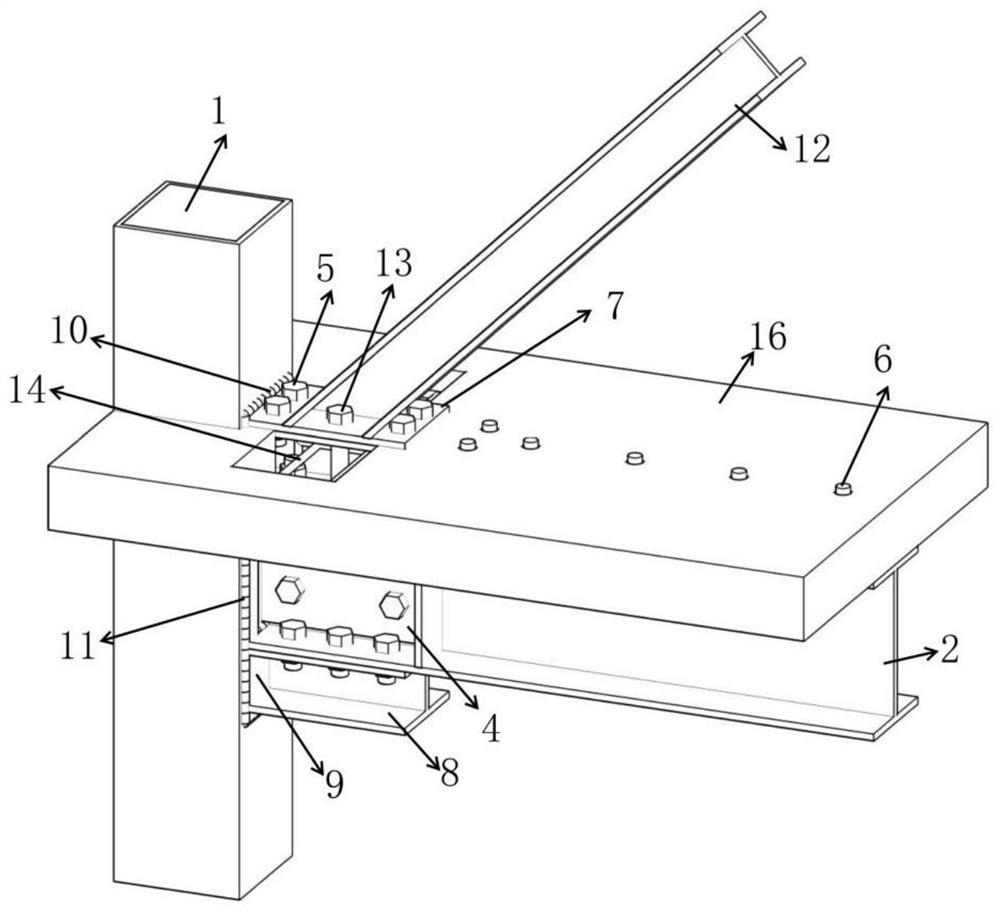

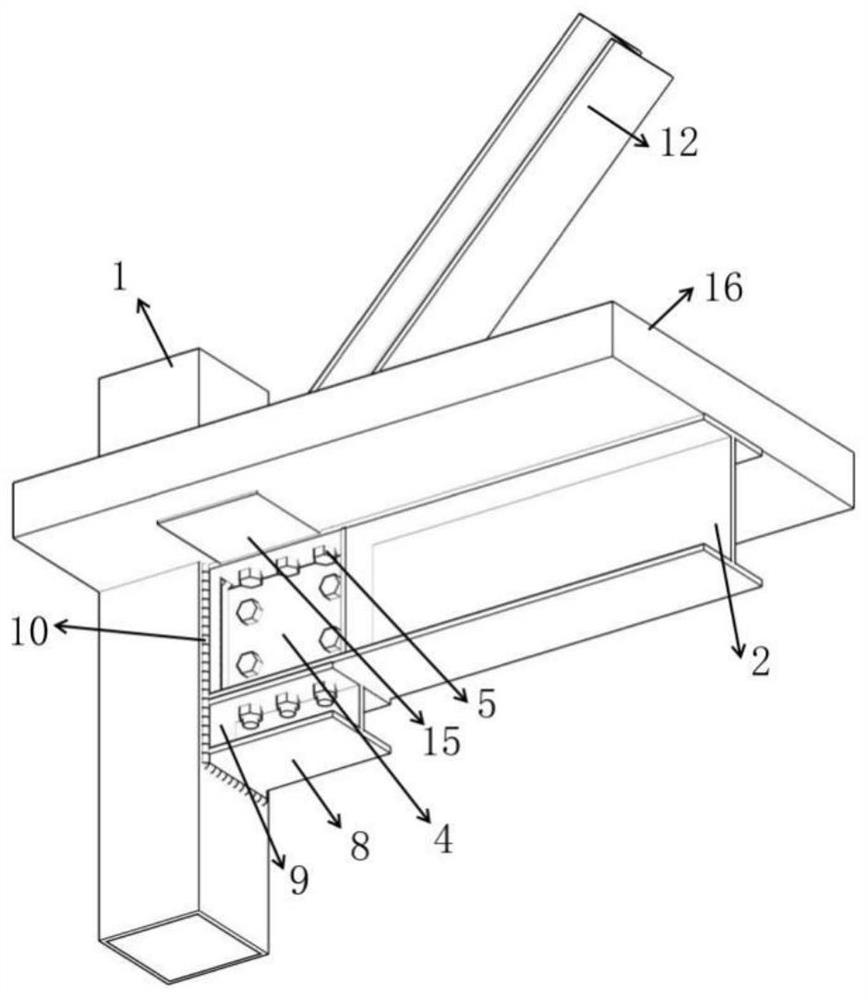

[0059] Such as image 3 As shown, a combined side column bottom node of a steel tube concrete column-H-shaped steel beam-steel support-π-shaped connector, the node includes a square steel tube recycled concrete column (1), an H-shaped steel beam (2), a π-shaped Connecting piece (3), web connecting plate (4), 30mm long high-strength bolt (5), floor shear stud (6), upper limb of π-shaped connecting piece (7), lower limb of π-shaped connecting piece (8), rectangular Bottom plate (9), outer fillet weld (10), inner fillet weld (11), steel support (12), 70mm through high-strength bolts (13), bench reinforcement (14), grouting material pallet (15), precast Recycled concrete floor (16) and floor reinforcement (17).

[0060] According to the size of the building load, the required bearing capacity of the steel pipe recycled concrete column can be calculated, and the steel pipe recycled co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com