Graphene oxide enhanced titanium alloy and preparation method thereof

A graphene and titanium alloy technology, applied in the field of titanium alloy, can solve the problems of poor plastic deformation ability, complex process, low tensile strength, etc., and achieve the effect of improving ductility, simple composition design, excellent strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

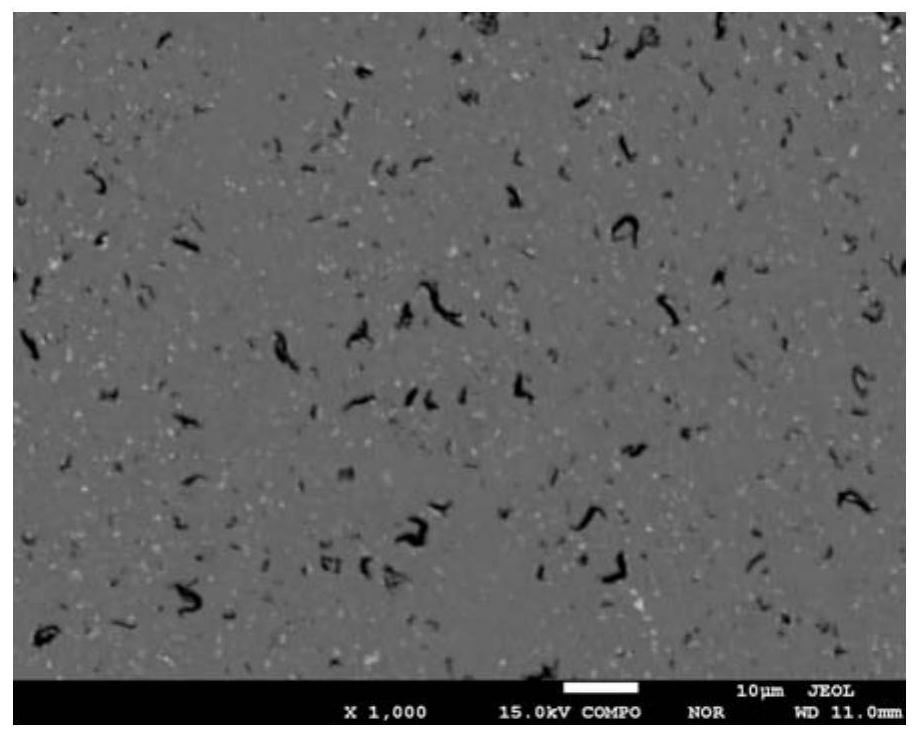

Image

Examples

preparation example Construction

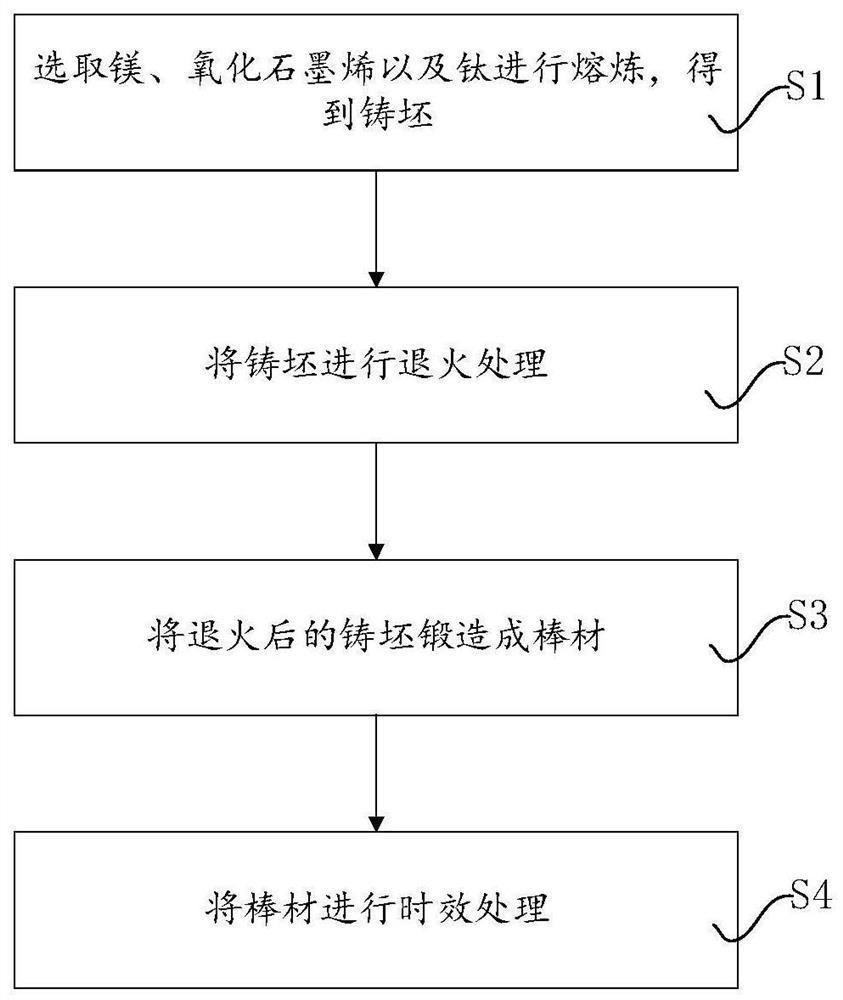

[0040] See figure 2 Graphene oxide prepared reinforced titanium alloy of the present invention, comprising the steps of:

[0041] S1: Select magnesium, titanium and graphene oxide was melted to obtain slab; wherein, in weight percent, Mg: 0.10% to 0.30%; graphene oxide: 0.45% to 0.50%; Ti: 99.20% ~ 99.45%.

[0042] Specifically, the selection magnesium, graphene oxide, and titanium was melted, the suspension by vacuum melting casting method, and the degree of vacuum furnace ≤10 -2 Pa, furnace temperature of 1600 ℃. Wherein the zero-order titanium sponge titanium, magnesium, and the purity of the graphene oxide were titanium ≥99.99%.

[0043] Preferably, further comprising: performing the slab cooling after scalping the billet, the billet surface oxide layer was removed.

[0044] S2: The cast slab is annealed, an annealing temperature of 910 ~ 960 ℃.

[0045] Specifically, the billet is annealed in a resistance furnace, an annealing temperature of 910 ~ 960 ℃, IH holding time, cool...

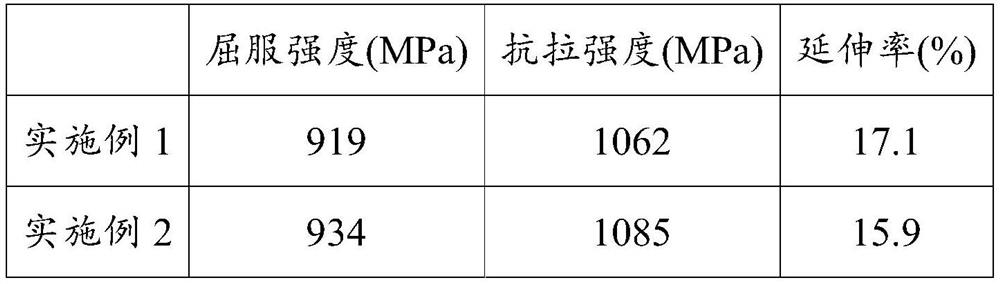

Embodiment 1

[0052] 1, ingredients: in weight percent, in accordance with magnesium: 0.10%; graphene oxide: 0.45%; the ratio of titanium and the balance being unavoidable impurities, were taken with the zero grade sponge Ti, Mg, and commercially pure graphene oxide. And, zero grade sponge Ti, Mg, and the purity of commercially pure graphene oxide was ≥99.99%.

[0053] 2, melting and casting: suspension smelting by vacuum casting method. When the melting furnace to control the degree of vacuum ≤10 -2 Pa, furnace temperature of 1600 ℃, to obtain an alloy billet. Strips of the slab cooled sufficiently for removing the billet surface oxide layer.

[0054] 3, homogenizing annealing treatment: treatment resistance furnace annealing, the annealing temperature of 910 deg.] C, IH holding time, the cooling mode is selected to furnace cooling.

[0055] 4, the forging process: forging the billet into bars, wherein the forging temperature of from 960 deg.] C, the final forging temperature of 800 deg.] C, w...

Embodiment 2

[0058] 1, ingredients: in weight percent, in accordance with magnesium: 0.20%; graphene oxide: 0.45%; the ratio of titanium and the balance being unavoidable impurities, were taken with the zero grade sponge Ti, Mg, and commercially pure graphene oxide. And, zero grade sponge Ti, Mg, and the purity of commercially pure graphene oxide was ≥99.99%.

[0059] 2, melting and casting: suspension smelting by vacuum casting method. When the melting furnace to control the degree of vacuum ≤10 -2 Pa, furnace temperature of 1600 ℃, to obtain an alloy billet. Strips of the slab cooled sufficiently for removing the billet surface oxide layer.

[0060] 3, homogenizing annealing treatment: treatment resistance furnace annealing, the annealing temperature is 930 ℃, IH holding time, the cooling mode is selected to furnace cooling.

[0061] 4, the forging process: forging the billet into bars, wherein the forging temperature of from 960 deg.] C, the final forging temperature of 800 deg.] C, when th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com