A converter flue gas high temperature cyclone dust removal waste heat boiler integrated device and method

A converter flue gas and cyclone dust removal technology, which is applied to furnaces, waste gas treatment, furnace components, etc., can solve the problems of inconvenient installation and maintenance, long maintenance cycle, waste, etc., to save equipment, reduce maintenance and repair, and reduce fan power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Conjunction with the drawings, the embodiments of the present invention will be further described.

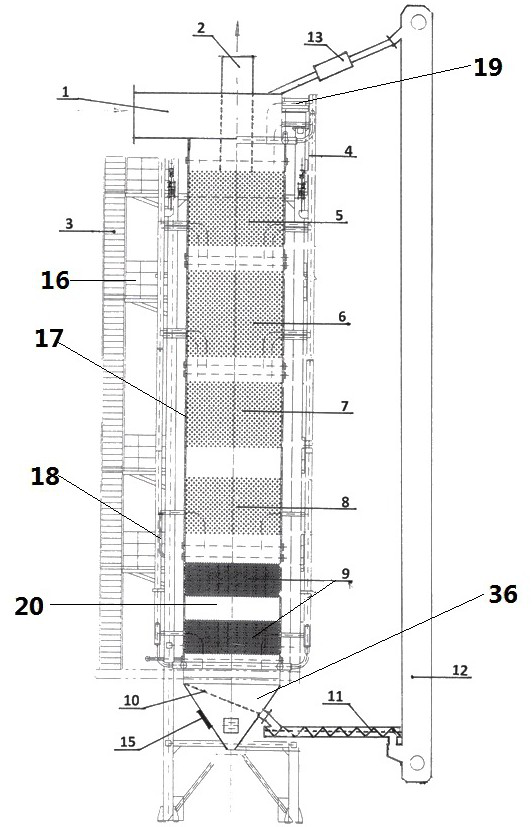

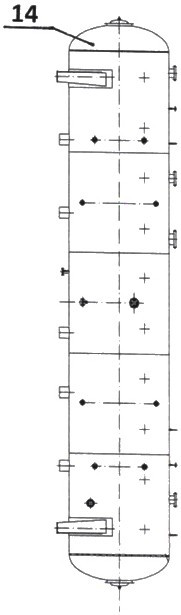

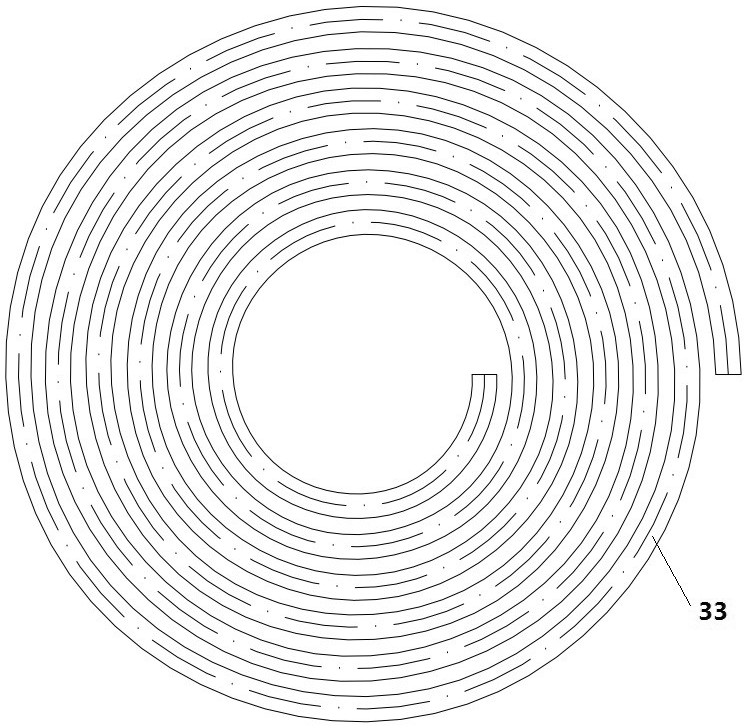

[0029]A converter flue gas high temperature cyclone dust removing heat boiler integrated device, including converter flue gas high temperature inlet 1, converter flue gas low temperature outlet 2, cylindrical furnace body 17, steel frame 30, multi-stage heat transfer unit, heat transfer unit steam heat pipe 4, the softening water pipe 18 and the steam steam pucer 14; the tubular furnace body 17 is provided with a multi-segment heat transfer unit, the multi-segment heat transfer unit, which is sequentially set up, a Type A heat exchange unit 5, a B type B heat exchange unit, and The C-type heat exchange unit 9 is spliced, the heat exchange tube of the A type heat exchange unit 5 is a multilayer disc-shaped tube bundle 33, and the disc is arranged as a disk-shaped tube bundle 33 on one planar, and the multi-layer disc shaped tube bundle 33 mutual Parallel arrangement within th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com