Alkaline earth metal ion doped rare earth tantalate or niobate thermal barrier coating and preparation method thereof

A technology of alkaline earth metal ion and thermal barrier coating, which is applied in metal material coating technology, coating, fusion spraying, etc., can solve the problems of high thermal conductivity, low thermal expansion coefficient, and low operating temperature of 6-8YSZ, etc. Achieve the effect of weak interface effect and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

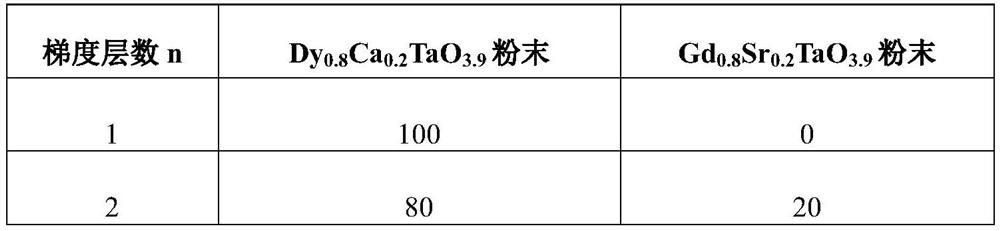

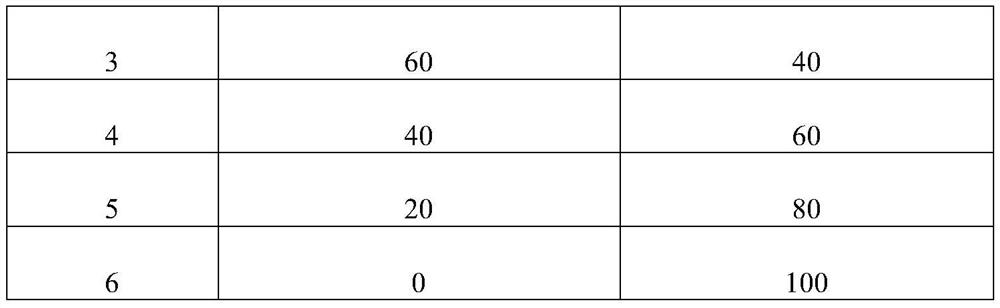

[0032] An alkaline earth metal ion-doped rare earth tantalate thermal barrier coating, which is a multi-component gradient coating, including two different ceramic components, and at least one of the ceramic components has a volume fraction along the coating gradient Continuously increasing or decreasing changes, the chemical general formula of the two ceramic components in the present embodiment 1 is Dy 0.8 Ca 0.2 TaO 3.9 and Gd 0.8 Sr 0.2 TaO 3.9 , the volume fraction ratio of the two ceramic components in each gradient coating is shown in Table 1.

[0033] In addition, the above-mentioned preparation method of alkaline earth metal ion doping rare earth tantalate or niobate, in order to prepare Dy 0.8 Ca 0.2 TaO 3.9 As an example, the following steps are included:

[0034] Step 1: Follow Dy 0.8 Ca 0.2 TaO 3.9 The structural formula will be Dy 2 o 3 and CaCO 3 The powder is dissolved in concentrated nitric acid for reaction, and the pH is adjusted to about 1, an...

Embodiment 2

[0043] The difference from Example 1 is that, as shown in Table 2, the number of gradient layers n=11, the thickness of the rare earth tantalate coating doped with alkaline earth metal ions is 300 μm, and Dy in each gradient layer 0.8 Ca 0.2 TaO 3.9 and Gd 0.8 Sr 0.2 TaO 3.9 The volume fraction of the powder is shown in Table 2 below.

[0044] Table 2 is Dy in each gradient layer of embodiment 2 0.8 Ca 0.2 TaO 3.9 and Gd 0.8 Sr 0.2 TaO 3.9 Volume fraction of powder (%)

[0045] Number of gradient layers n Dy 0.8 Ca 0.2 TaO 3.9 powder

Embodiment 3

[0047] The difference from Example 1 is that, as shown in Table 3, the number of gradient layers of the ceramic coating n=21, the thickness of the alkaline earth metal-doped rare earth tantalate coating is 400 μm, and Dy in each gradient layer 0.8 Ca 0.2 TaO 3.9 and Gd 0.8 Sr 0.2 TaO 3.9 The volume fraction of the powder is shown in Table 3 below.

[0048] Table 3 is Dy in each gradient layer of embodiment 3 0.8 Ca 0.2 TaO 3.9 and Gd 0.8 Sr 0.2 TaO 3.9 Volume fraction of powder (%)

[0049]

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com