Nanosheet-shaped lithium titanate material with oriented structure and preparation method and application thereof

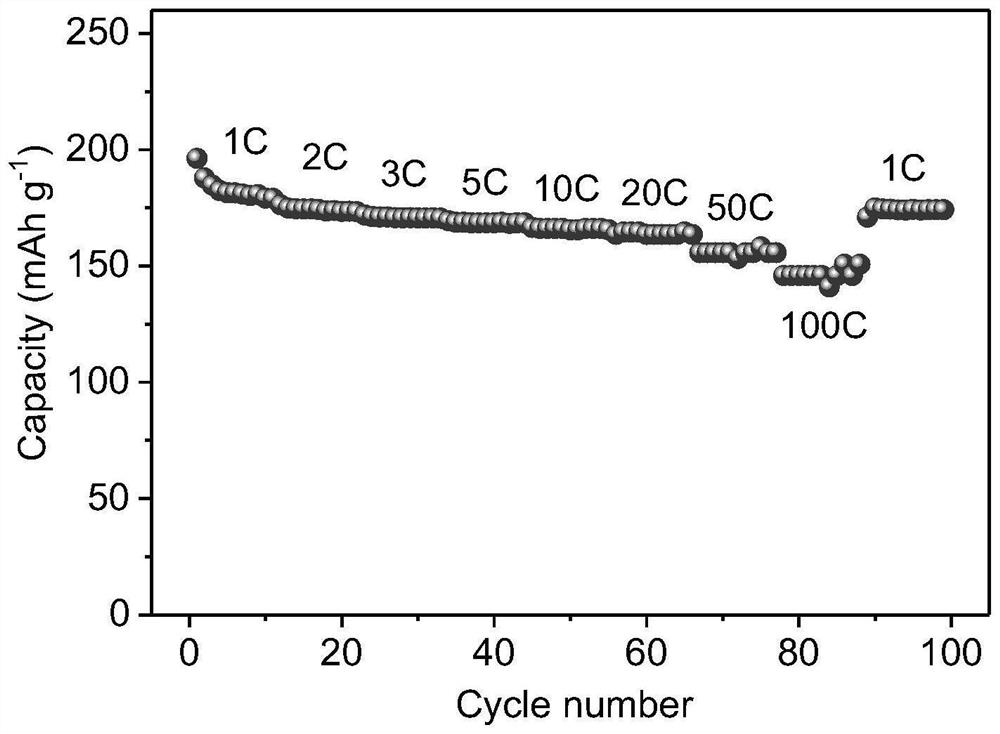

A flake lithium titanate, orientation technology, applied in titanate, structural parts, alkali metal titanate and other directions, can solve the problems of electrochemical side reactions, limit the inherent advantages of lithium titanate materials, and achieve good safety , Improve fast charge and discharge capacity, solve the effect of low ion mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

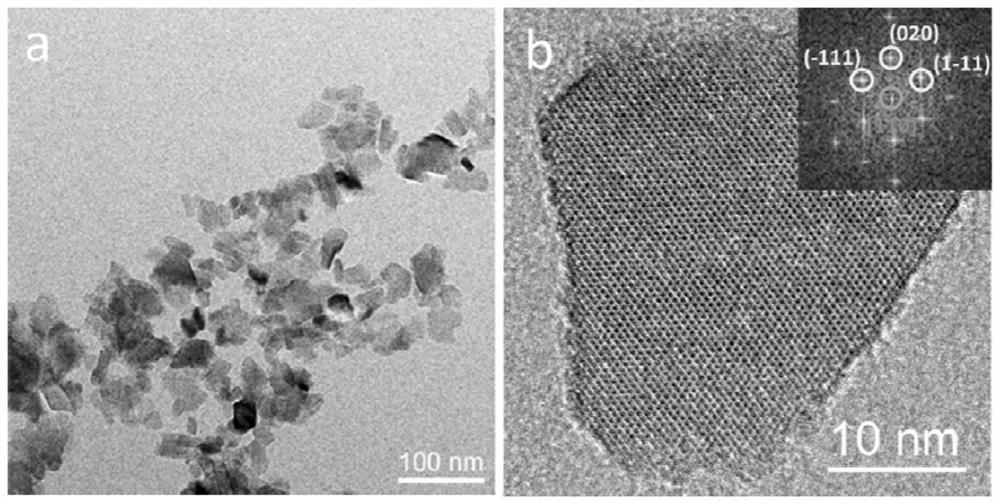

[0028] The preparation of nano flake lithium titanate material, the steps are as follows:

[0029] (1) Measure 0.5mL TiCl with a pipette gun 4 solution and slowly added to 20mL of ethylene glycol, fully stirred at room temperature, then added 2mL of tetraalkylammonium hydroxide aqueous solution (mass fraction is 25%), after stirring for 20min, the mixture was transferred to a polytetrafluoroethylene reactor , hydrothermally reacted at 150°C for 24 hours, washed the product with deionized water and ethanol respectively after the reaction, and dried at 60°C for later use;

[0030] (2) Weigh 30mg of the product obtained in step (1), add it to 15mL lithium hydroxide solution (1mol / L), transfer it to a polytetrafluoroethylene reactor after fully stirring, and conduct a hydrothermal reaction at 140°C for 1h, and the reaction is complete Afterwards, the product is washed by the method of step (1) and dried;

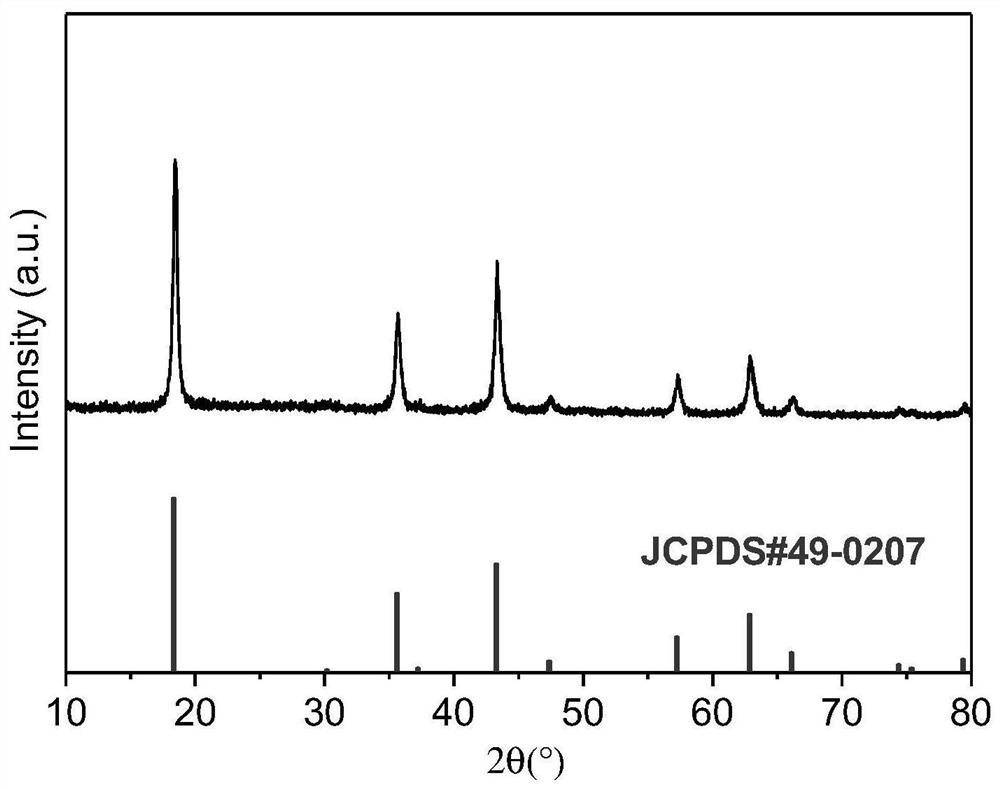

[0031] (3) Transfer the dried product of step (2) to a crucible, and calc...

Embodiment 2

[0033] The difference between the method for preparing nano-flaky lithium titanate material in this example and Example 1 is that the hydrothermal reaction solvent used in step (1) of this example is propylene glycol, and the temperature of the hydrothermal reaction is 140°C. The calcining temperature in step (3) is 600°C.

Embodiment 3

[0035] The difference between the method for preparing the nanosheet-shaped lithium titanate material in this example and Example 1 is that the temperature of the hydrothermal reaction used in step (1) of this example is 130° C., and the reaction time is 12 hours. The calcination temperature in step (3) is 700° C., and the calcination time is 1 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com