Tin-based organic metal framework material, preparation method thereof and application of tin-based organic metal framework material in lithium ion battery negative electrode material

A lithium-ion battery, organic metal technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problem of high cost of tin-based metal-organic framework materials, improve rapid charge and discharge capacity, shorten migration path, the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of a tin-based organometallic framework material, specifically comprising the following steps:

[0035] S1, the phthalic acid solution that concentration is 0.01-0.1mol / L is joined in the sodium hydroxide solution that concentration is 0.05-0.2mol / L, stir, obtain mixed solution;

[0036] Wherein, the molar ratio of the added amount of phthalic acid and sodium hydroxide ranges from 1:1 to 1:5.

[0037] S2. Sn with a concentration of 0.1-0.5mol / L 2+ The aqueous solution is dropped into the mixed solution at a rate of 0.1-2mL / min, and then continuously stirred at 10-50°C for 2-8h to obtain a white precipitate;

[0038] Among them, Sn 2+ The aqueous solution is stannous sulfate aqueous solution, stannous chloride aqueous solution or tin acetate aqueous solution;

[0039] Among them, phthalic acid: Sn 2+ The molar ratio of the added amount ranges from 1:1 to 1:3.

[0040] S3, the white precipitate is separated and washed by vacuum filtration, and fi...

Embodiment 1

[0043] A preparation method of a tin-based organometallic framework material, comprising the following steps:

[0044] S1. Add 150 mL of phthalic acid aqueous solution (0.08 mol / L) to 150 mL (0.16 mol / L) of sodium hydroxide aqueous solution, and stir evenly.

[0045] S2. Add 60 mL of 0.25 mol / L stannous sulfate aqueous solution dropwise to the solution in step S1, and continuously stir at 20° C. for 5 h to obtain a white precipitate.

[0046]S3. The white precipitate obtained in S2 is separated and washed by vacuum filtration, washed alternately with distilled water and ethanol for 3 times, and the isolate is vacuum-dried at 60° C. to obtain a tin-based organometallic frame material.

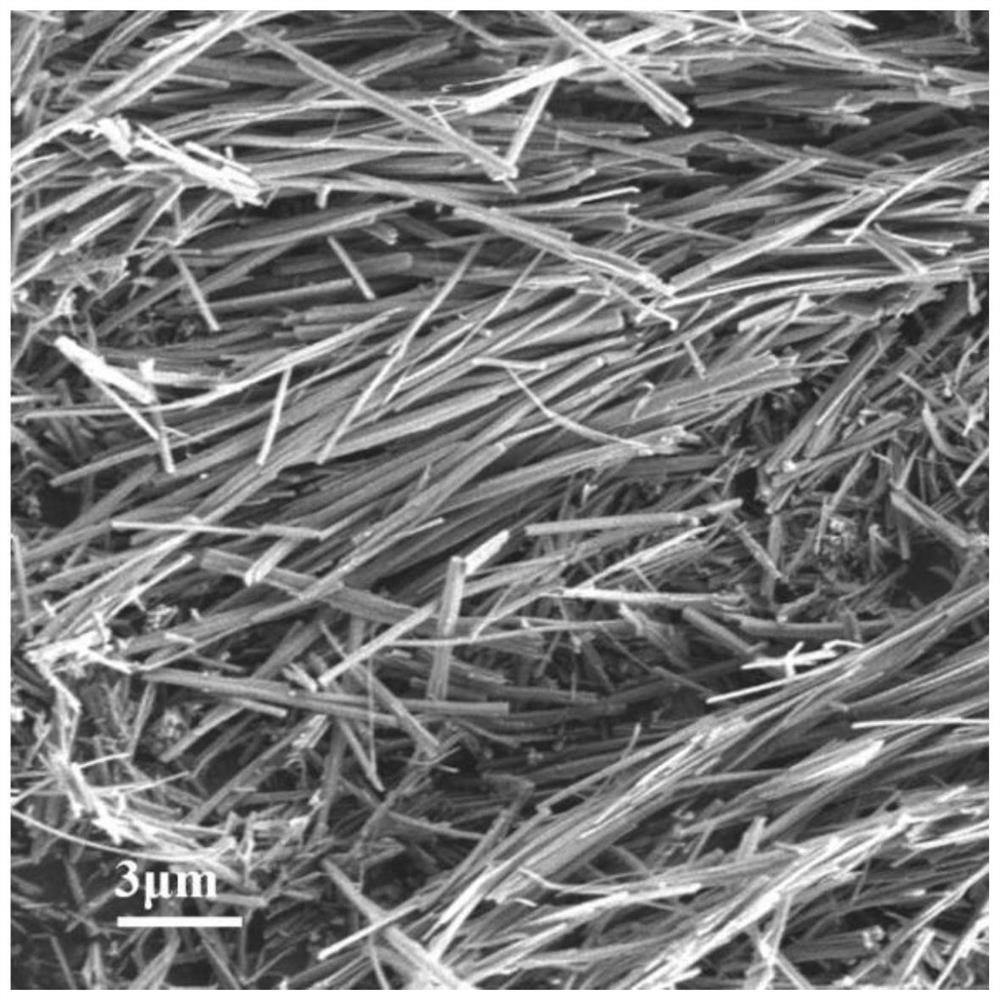

[0047] Scanning electron microscope image of the prepared product as figure 1 As shown, the material is a one-dimensional microrod-like structure with a smooth surface, the length of the microrod is 2-10 μm, and the diameter is 50-500 nm.

Embodiment 2

[0049] A preparation method of a tin-based organometallic framework material, comprising the following steps:

[0050] S1. Add 100 mL of phthalic acid aqueous solution (0.1 mol / L) to 200 mL (0.2 mol / L) of sodium hydroxide aqueous solution, and stir evenly.

[0051] S2. Add 50 mL (0.3 mol / L) stannous sulfate aqueous solution dropwise to the solution in step S1, and continue stirring at 25°C for 8 h to obtain a white precipitate.

[0052] S3. The white precipitate obtained in S2 is separated and washed by vacuum filtration, washed three times with distilled water, and the separated product is vacuum dried at 80° C. to obtain a tin-based organometallic framework material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com