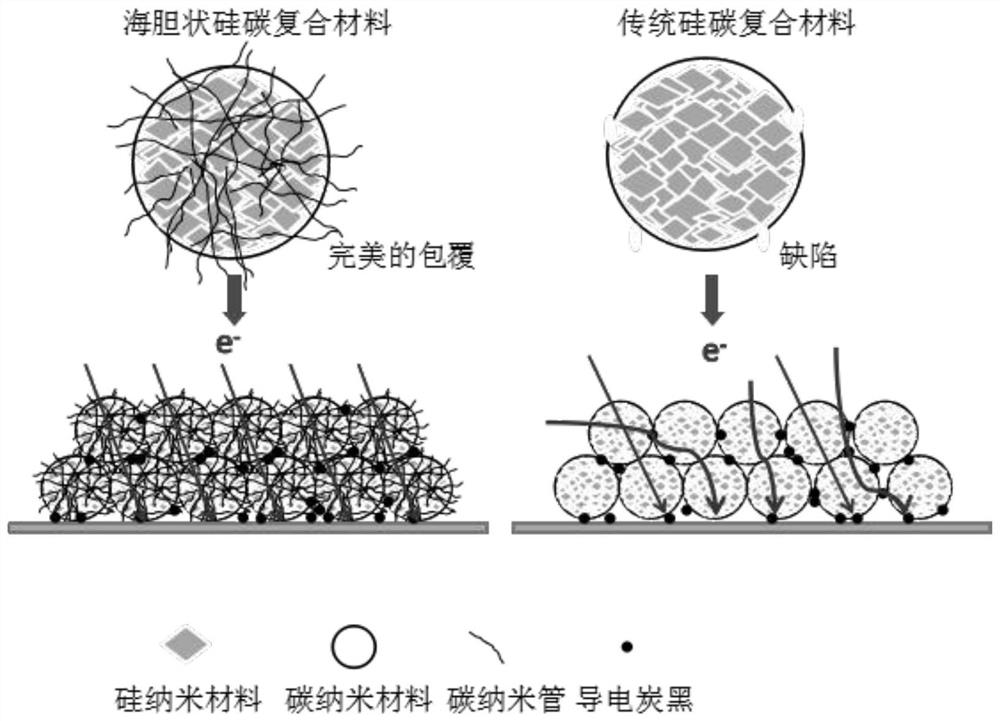

Sea urchin-shaped silicon-carbon composite material as well as preparation method and application thereof

A silicon-carbon composite material, sea urchin-like technology, applied in nanotechnology for materials and surface science, active material electrodes, nanotechnology, etc., can solve problems such as limiting the transmission of electrons and limiting the rapid charge and discharge performance of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing the sea urchin-shaped silicon-carbon composite material described in the above technical solution, comprising the following steps:

[0027] Mix silicon nanomaterials, hybrid carbon cage materials and solvents to obtain dispersions;

[0028] Spray drying the dispersion to obtain a silicon carbon precursor;

[0029] The silicon-carbon precursor is annealed to obtain the three-dimensional sea urchin-shaped silicon-carbon composite material.

[0030] In the present invention, unless otherwise specified, the raw materials used in the present invention are preferably commercially available products.

[0031] The invention mixes the silicon nanometer material, the hybrid carbon cage material and the solvent to obtain the dispersion liquid.

[0032] In the present invention, the silicon nanomaterial preferably includes nano silicon. In the present invention, the particle size of the silicon nanomaterial is preferably...

Embodiment 1

[0044]Mixing nano-silicon, graphene oxide and carbon nanotubes prepared by the sand milling method in water at a mass ratio of 30:30:40 to obtain a dispersion;

[0045] Spray drying the dispersion at 200°C to obtain a silicon carbon precursor;

[0046] Under a hydrogen atmosphere, the silicon-carbon precursor was annealed at 800° C. for 60 minutes (the heating rate was 10° C. / min) to obtain a sea urchin-like silicon-carbon composite material; wherein the mass content of nano-silicon was 50%.

[0047] The prepared sea urchin-like silicon-carbon composite material was directly used as a high-performance negative electrode active material, and a slurry was prepared with conductive carbon black and PVDF at a mass ratio of 8:1:1, coated on a copper foil, and dried at 70°C for 2 hours. Use a slicer to cut pole pieces with a diameter of 12mm; use metal lithium foil as the counter electrode; the electrolyte is 1M LiPF 6 / EC: DEC (1:1; v / v), that is, a mixed solvent of ethylene carbon...

Embodiment 2

[0049] Mixing nano-silicon, graphene oxide and ferrocene prepared by the sand milling method in water at a mass ratio of 30:65:5 to obtain a dispersion;

[0050] Spray drying the dispersion at 220°C to obtain a silicon carbon precursor;

[0051] Under a hydrogen atmosphere, the silicon-carbon precursor was annealed at 1000° C. for 60 minutes (the heating rate was 10° C. / min) to obtain a sea urchin-shaped silicon-carbon composite material, wherein the mass content of nano-silicon was 45%.

[0052] Subsequent tests were as in Example 1.

[0053] Under the current density of 10A / g, the specific capacity of the sea urchin-like silicon-carbon composite material is 750mAh / g; after 300 cycles, the capacity retention rate can reach 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com