Nano hollow porous silicon material as well as preparation method and application thereof

A hollow porous, silicon material technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of complex preparation process of hollow silicon materials, achieve excellent electrochemical lithium storage reversibility, high cycle stability, Highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

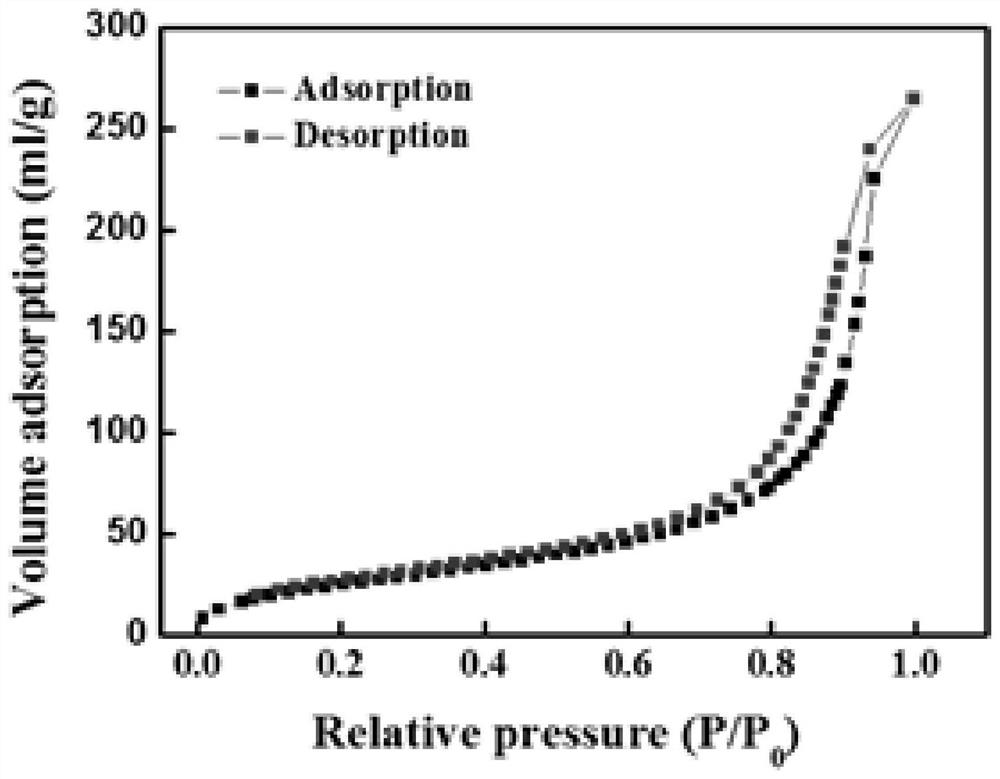

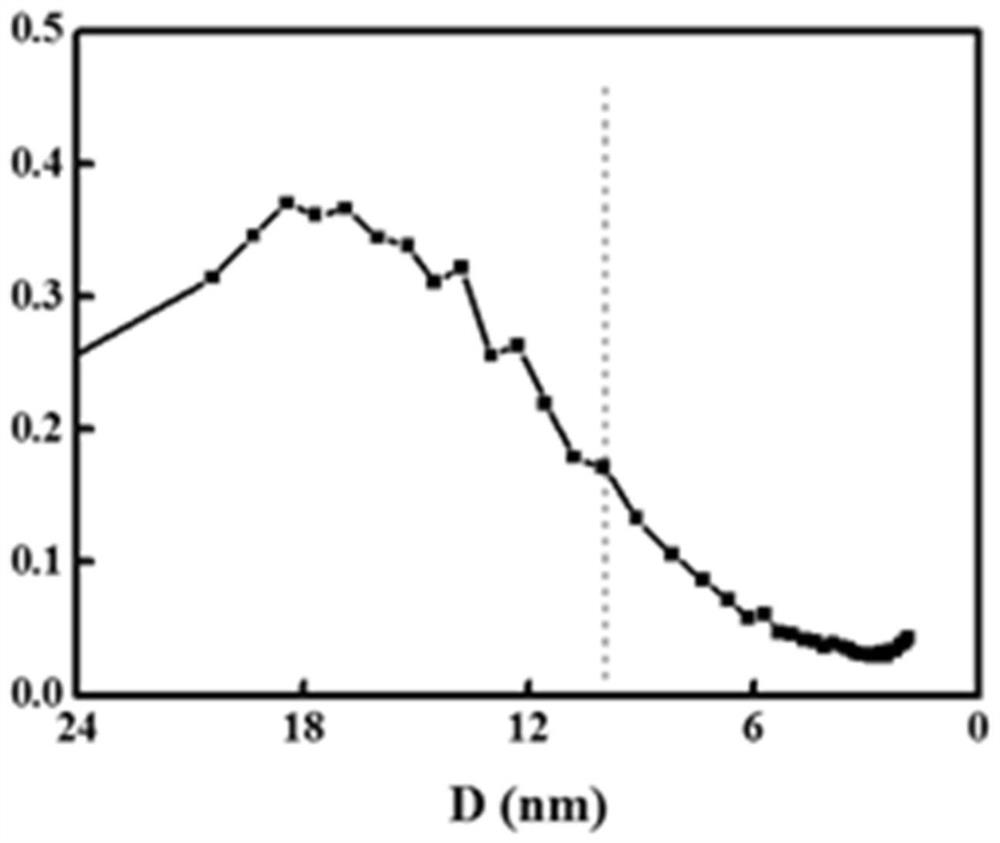

[0050] see figure 1 , Schematic diagram of the synthesis of nanoporous hollow silicon materials.

[0051] 1. Dissolve 1 g of cetyl ammonium chloride (CTAC) and 0.3 g of triethanolamine (TEOA) in 50 ml of deionized water, and perform ultrasonication at room temperature for 0.5 h to fully dissolve to obtain a mixture.

[0052] 2. Transfer the mixture in step 1 to an oil bath at 70° C., then add 1 mL of tetraethyl orthosilicate (TEOS) dropwise to the above system, and continue to stir and react in the constant temperature oil bath for 5 h.

[0053] 3. The reaction product in step 2 is centrifuged and washed with absolute ethanol, and dried to obtain the precursor hollow silica nanospheres.

[0054] 4. According to the chemical formula 2Mg+SiO 2 +7AlCl 3 +NaCl→Si+2MgAl 2 Cl 8 +2AlOCl+NaAlCl Calculate the amount used in the reaction, the precursor hollow silica nanospheres, aluminum chloride, sodium chloride and metal magnesium in step 3 are fully mixed in a glove box equipped...

Embodiment 2

[0058] see figure 1 , Schematic diagram of the synthesis of nanoporous hollow silicon materials.

[0059] 1. Dissolve 1 g of cetyl ammonium chloride (CTAC) and 0.3 g of triethanolamine (TEOA) in 50 ml of deionized water, and perform ultrasonication at room temperature for 0.5 h to fully dissolve to obtain a mixture.

[0060] 2. Transfer the mixture in step 1 to an oil bath at 80° C., then add 5 mL of tetraethyl orthosilicate (TEOS) dropwise to the above system, and continue to stir and react in the constant temperature oil bath for 6 h.

[0061] 3. The reaction product in step 2 is centrifuged and washed with absolute ethanol, and dried to obtain the precursor hollow silica nanospheres.

[0062] 4. Fully mix the precursor hollow silica nanospheres, aluminum chloride, sodium chloride and metal magnesium in a glove box equipped with argon (Ar) in step 3, put them into a stainless steel autoclave and seal it well, The stainless steel autoclave was then transferred to a muffle f...

Embodiment 3

[0066] see figure 1 , Schematic diagram of the synthesis of nanoporous hollow silicon materials.

[0067] 1. Mix the mass of cetyl ammonium chloride, the mass of triethanolamine, and deionized water at a volume ratio of 0.5:0.1:30, and magnetically stir at room temperature for 0.5 h to fully dissolve to obtain a mixture.

[0068] 2. Transfer the mixture in step 1 to an oil bath at 80° C., then add 1 mL of tetraethyl orthosilicate (TEOS) dropwise to the above system, and continue to stir and react in the constant temperature oil bath for 6 h.

[0069] 3. The reaction product in step 2 is centrifuged and washed with absolute ethanol, and dried to obtain precursor hollow silica nanospheres with a diameter of about 400-500 nm.

[0070] 4. Fully mix the precursor hollow silica nanospheres, aluminum chloride, sodium chloride and metal magnesium with a mass ratio of 1:4.4:1.2:1 in a glove box filled with argon (Ar), and put Put it in a stainless steel autoclave and seal it well, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com