A lithium power energy storage battery multi-electrode rolling machine

A power energy storage battery and rolling machine technology, which is applied in the field of rolling machines, can solve the problems of reducing the rolling efficiency, the application range of the rolling machine, the electrode being crushed, and the operation is inconvenient, so as to avoid the electrode being crushed, The effect of improving the rolling efficiency and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

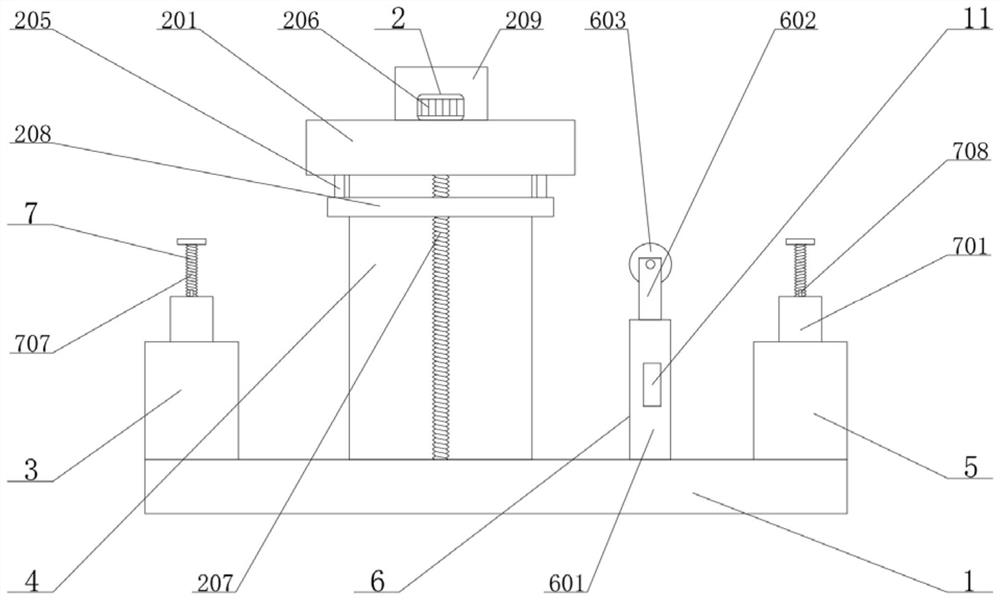

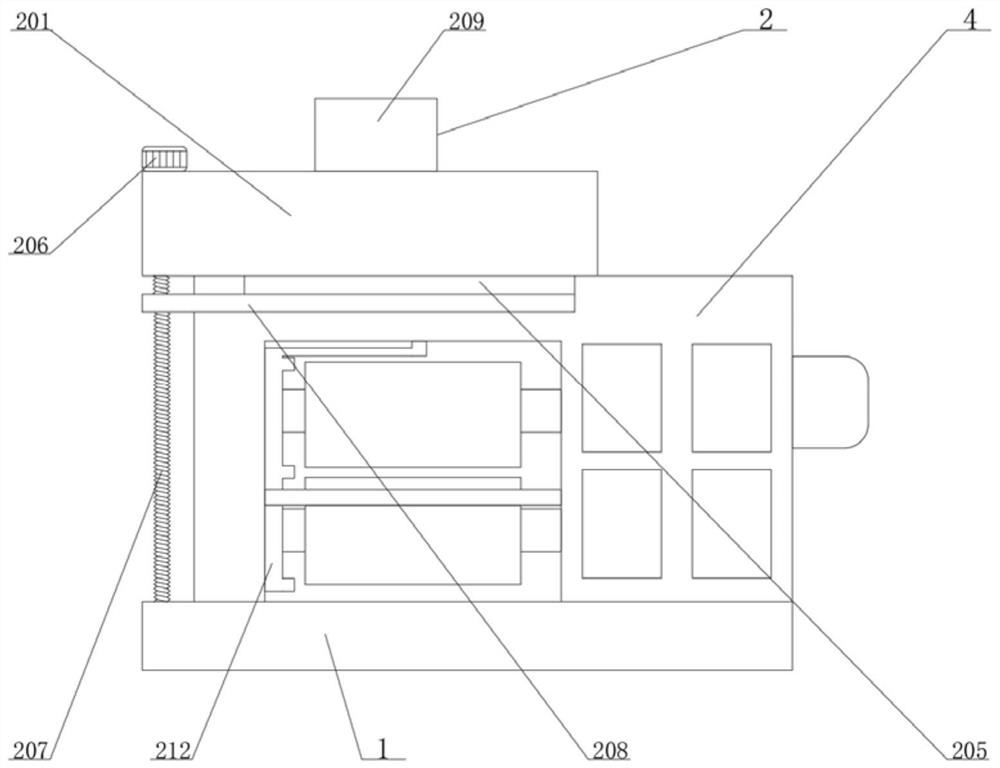

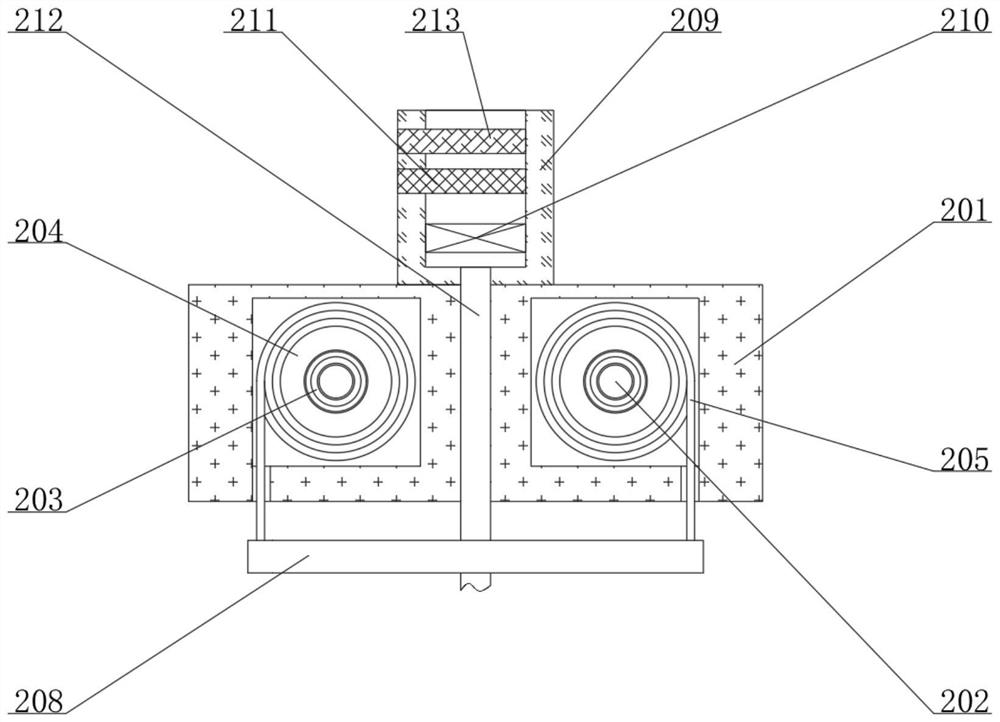

[0026] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , the present invention provides a technical solution:

[0027]A lithium power energy storage battery multi-electrode rolling machine, including a base 1, a protection device 2, a detection device 6 and a limit device 7, the top of the base 1 is fixedly connected with a discharge frame 3 and a rolling machine 4 in sequence from left to right , detection device 6 and material receiving frame 5, detection device 6 comprises sleeve rod 601, inner rod 602, rotating roller 603, first spring 604, second spring 605, slide plate 606, first control switch 607 and alarm 608, receive The left side of the material rack 5 is provided with a sleeve rod 601, and the sleeve rod 601 is fixedly connected with the base 1, the inner top of the sleeve rod 601 is slidingly connected with an inner rod 602, the outer top of the inner rod 602 is rotatably connected with a rotating roller 603, and the outer bottom of ...

Embodiment 2

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , the present invention provides a technical solution:

[0031]A lithium power energy storage battery multi-electrode rolling machine, including a base 1, a protection device 2, a detection device 6 and a limit device 7, the top of the base 1 is fixedly connected with a discharge frame 3 and a rolling machine 4 in sequence from left to right , detection device 6 and material receiving frame 5, detection device 6 comprises sleeve rod 601, inner rod 602, rotating roller 603, first spring 604, second spring 605, slide plate 606, first control switch 607 and alarm 608, receive The left side of the material rack 5 is provided with a sleeve rod 601, and the sleeve rod 601 is fixedly connected with the base 1, the inner top of the sleeve rod 601 is slidingly connected with an inner rod 602, the outer top of the inner rod 602 is rotatably connected with a rotating roller 603, and the outer bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com