Hydrogen evolution electrocatalytic material and preparation method and application thereof

An electrocatalytic material and a technology for catalytic materials, applied in the field of hydrogen evolution electrocatalytic materials and their preparation, can solve the problems of small specific surface area of composite materials, agglomeration of metal nanoparticles, lack of confinement and immobilization, etc. High specific surface area, the effect of promoting electron conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of polystyrene (PS) sphere template: Monodisperse polystyrene spheres were synthesized by emulsion polymerization. Ultrapure water (1100ml, 18MΩcm -2 @25°C) and styrene (13 mL) were added to a three-neck round bottom flask (500 mL). The mixture was stirred at a speed of 600 rpm while heating to 70 °C, and was blown with nitrogen at 60 mL min -1 The flow rate of purge. After keeping the mixture at 70 °C for 30 min, K 2 S 2 o 8 (0.3g), and the reaction was continued for 24 hours. The obtained polystyrene spheres were centrifuged at a speed of 4000 rpm to remove large aggregates at the bottom, and the upper emulsion was recovered and dried overnight at 60° C. to obtain a three-dimensionally ordered PS template.

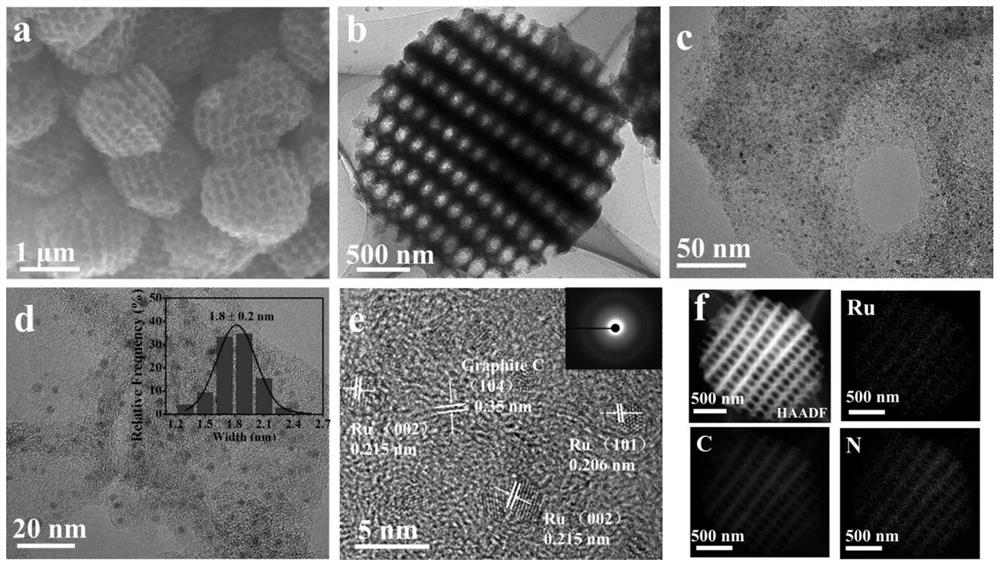

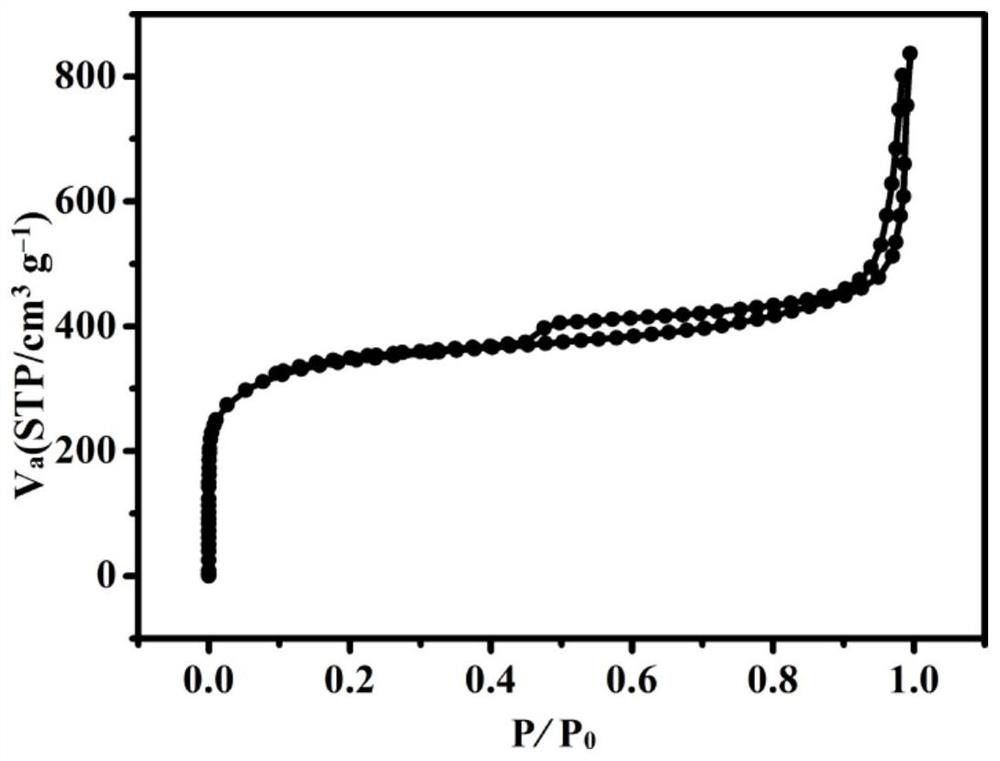

[0052] (2) The PS template (2.0 g) prepared in step (1) was immersed in the Zn(NO 3 ) 2 ·6H 2 O (0.029g / mL), 2-methylimidazole (0.024g / mL) and 0.080g RuCl 3 ·xH 2 O in methanol solution (22.5 mL) for 1 h, degassed in vacuum for 10 min, a...

Embodiment 2

[0054] (1) The preparation of the polystyrene (PS) spherical template is the same as that in the step (1) of Example 1.

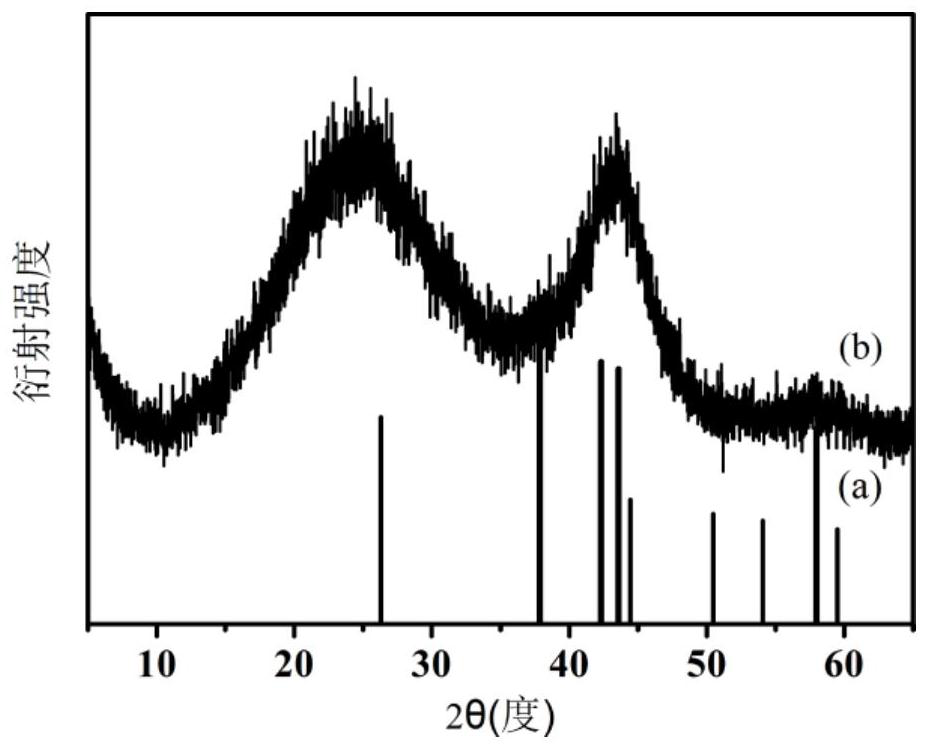

[0055] (2) The PS template (2.0 g) prepared in step (1) was immersed in the Zn(NO 3 ) 2 ·6H 2 O (0.029g / mL) and 2-methylimidazole (0.024g / mL) in a methanol solution (22.5mL) for 1 hour, vacuum degassed for 10 minutes, and then the impregnated template was removed and placed at 50 °C Dry under vacuum for 6 hours. Then dip the dried template into CH 3 OH / NH 3 ·H 2 O mixed solution (1:1=v / v), vacuum degassed for 10 minutes and then stood at room temperature for 24 hours, the product was filtered off and dried at room temperature. Then the product was immersed in tetrahydrofuran to etch the PS template, and the light brown powder was filtered out and dried overnight at 110°C. Finally, the light brown powder product was placed in a porcelain boat, heated to 950 °C at a heating rate of 2 °C / min, kept for 1 h, and then naturally cooled to room temperature t...

Embodiment 3

[0057] Mix 6.5g 2-methylimidazole and 0.08g RuCl under vigorous stirring 3 ·xH 2 O was dissolved in 80 mL of methanol solution. Then add 3g Zn(NO 3 ) 2 ·6H 2 O in 40 mL of methanol, stirred vigorously for 24 hours. The obtained product was separated by centrifugation, washed several times with methanol, and dried under vacuum at 60°C overnight. Finally, the product was placed in a porcelain boat, heated to 950 °C at a heating rate of 2 °C / min, and kept for 1 h, and then naturally cooled to room temperature to obtain a Ru loading of 1.5 wt % and a nitrogen doping amount of 6.6 at % hydrogen evolution electrocatalytic materials. The whole process was carried out in an Ar atmosphere, and the flow rate of the Ar gas was controlled at 25 mL / min.

[0058] In the hydrogen evolution electrocatalytic material obtained in this example, Ru nanoparticles are supported in a nitrogen-doped carbon framework obtained by high-temperature carbonization of a rhombohedral microporous ZIF-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com