Curved heterojunction solar cell and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in the field of solar cells, can solve problems such as unfavorable light-absorbing layer and electrode preparation, defects introduced into cells, and limited cell efficiency, so as to solve the problem of disordered distribution of built-in electric field and inconsistent direction of charge collection, and improve Charge transport efficiency, effect of increasing interface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

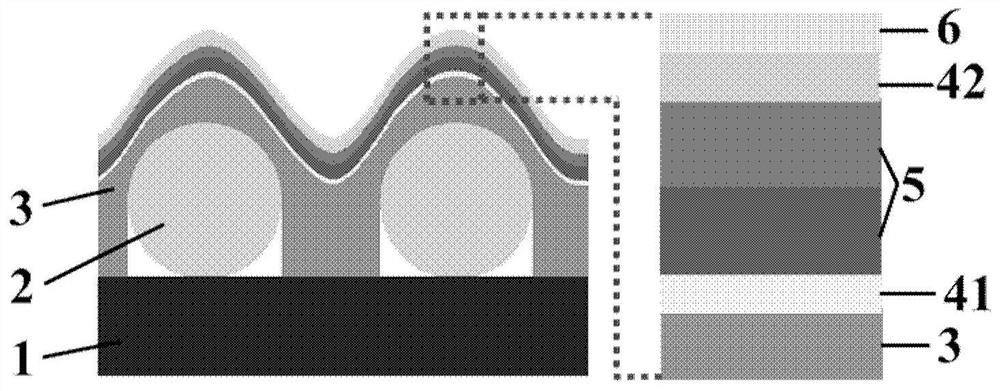

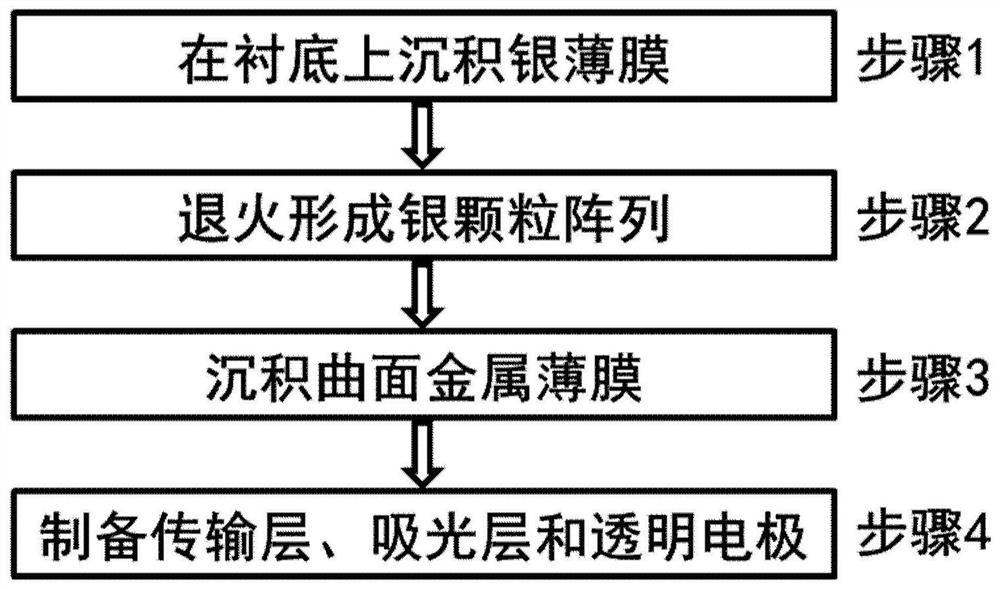

[0029] In order to solve the problem of direct contradiction between light absorption and charge transmission efficiency in solar cells, the invention provides a curved surface heterojunction solar cell structure and a manufacturing method thereof. This structure not only has a better light-trapping effect, but also can achieve high-quality preparation of a thinner light-absorbing layer, and the curved light-trapping structure is less likely to introduce defects into the light-absorbing layer than the sharp light-trapping structure.

[0030] The invention discloses a curved surface heterojunction solar cell, comprising:

[0031] Substrate;

[0032] an array of silver nanoparticles disposed on a substrate;

[0033] Curve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com