Manufacturing method of vacuum tinned plate

A manufacturing method and vacuum plating technology, applied in the field of metal material manufacturing, can solve the problems of easily corroded equipment, affecting product quality, high volatility of hydrochloric acid, etc., and achieve the effect of avoiding surface oxidation, eliminating pickling process, and excellent coating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

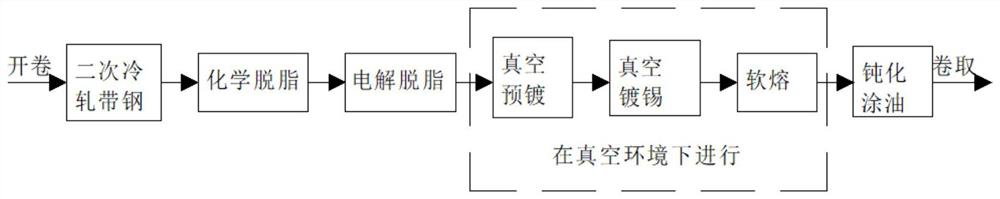

[0038] In this embodiment, DC06 steel is selected as the substrate, chromium is used as the pre-coating material, and tin is used as the top layer. Prepare the corrosion-resistant coating according to the following steps (such as figure 2 shown):

[0039] ① Carry out chemical degreasing, electrolytic degreasing, rinsing and drying on the strip steel to remove pollutants such as grease and solid particles on the surface;

[0040] ②The steel strip enters the vacuum chamber that has been evacuated through the inlet vacuum lock. The surface of the steel strip is preheated to 250°C, and then argon gas is introduced to clean the surface of the steel strip with plasma. The cleaning time is 5 minutes;

[0041] ③Keep the vacuum degree of the vacuum chamber at 4×10 -3 Pa, select the magnetron sputtering coating process to deposit a chromium pre-coating layer on the surface of the steel plate, and the thickness of the pre-coating layer is 10nm;

[0042] ④Keep the vacuum degree of the...

Embodiment 2

[0047] In this embodiment, DC06 steel is selected as the substrate, chromium is used as the pre-coating material, and tin is used as the top layer. Follow the steps below to prepare the corrosion resistant coating:

[0048] ① Carry out chemical degreasing, electrolytic degreasing, rinsing and drying on the strip steel to remove pollutants such as grease and solid particles on the surface;

[0049] ②The steel strip enters the vacuum chamber that has been evacuated through the inlet vacuum lock. The surface of the steel strip is preheated to 200°C, and then argon gas is introduced to clean the surface of the steel strip with plasma. The cleaning time is 10 minutes;

[0050] ③Keep the vacuum degree of the vacuum chamber at 2×10 -2 Pa, select the magnetron sputtering coating process to deposit a chromium pre-coating layer on the surface of the steel plate, and the thickness of the pre-coating layer is 20nm;

[0051] ④Keep the vacuum degree of the vacuum chamber at 4×10 -2 Pa, u...

Embodiment 3

[0056] In this embodiment, DC06 steel is selected as the substrate, chromium is used as the pre-coating material, and tin is used as the top layer. Follow the steps below to prepare the corrosion resistant coating:

[0057] ① Carry out chemical degreasing, electrolytic degreasing, rinsing and drying on the strip steel to remove pollutants such as grease and solid particles on the surface;

[0058] ②The steel strip enters the vacuum chamber that has been evacuated through the inlet vacuum lock. The surface of the steel strip is preheated to 200°C, and then argon gas is introduced to clean the surface of the steel strip with plasma. The cleaning time is 10 minutes;

[0059] ③Keep the vacuum degree of the vacuum chamber at 2×10 -2 Pa, select the multi-arc ion plating process to deposit a chromium pre-coating layer on the surface of the steel plate, and the thickness of the pre-plating layer is 20nm;

[0060] ④Keep the vacuum degree of the vacuum chamber at 4×10 -2 Pa, a tin la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com