Method for preparing polyolefin in-kettle alloy and polyolefin in-kettle alloy prepared by method

A technology for alloying and polyolefin in a kettle, applied in the field of olefin polymerization, can solve the problems of large amount of monomers, reduced polymerization reaction activity, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

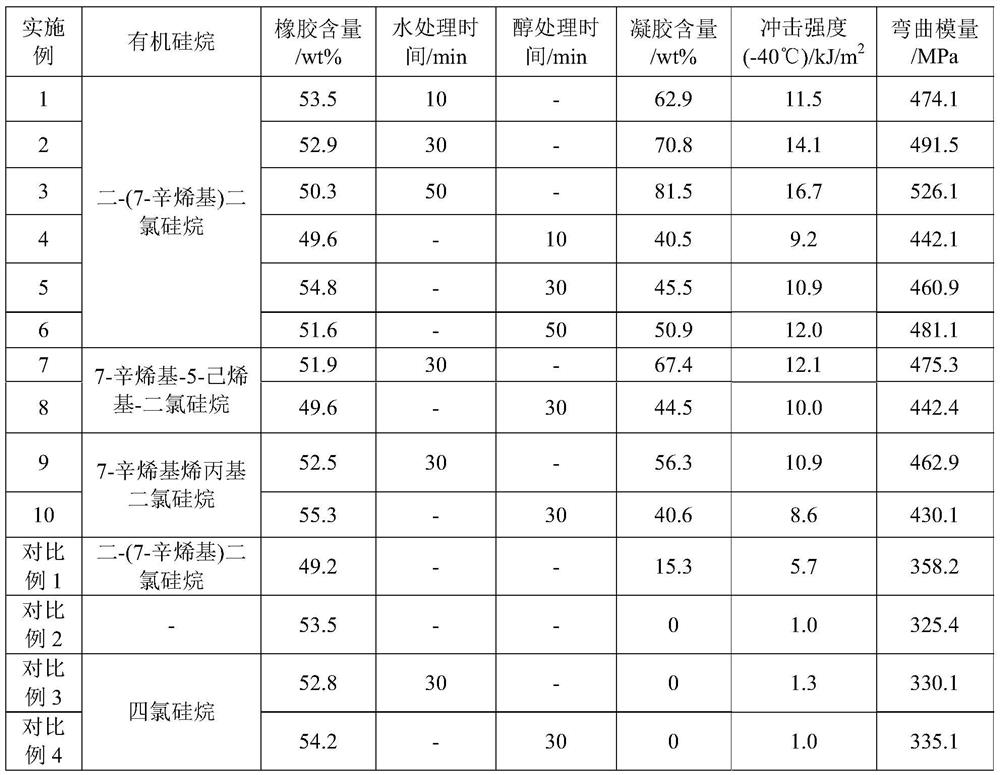

Examples

preparation example Construction

[0025] The preparation method of polyolefin still alloy provided by the invention comprises the following steps:

[0026] 1) Use the first olefin monomer to carry out the first polymerization reaction in the presence of a catalyst, and then pass the second olefin monomer into the polymerization reaction system to carry out the second polymerization reaction, and the first olefin monomer is different from the second olefin a monomer, the first polymerization and / or the second polymerization is carried out in the presence of an organosilane;

[0027] 2) making water and / or alcohol contact with the product obtained in step 1),

[0028] Wherein, the general formula of the organosilane is R 1 m SiX n R 2 k , where R 1 for C 7 -C 20 1-Alkenyl, R 2 for C 2 -C 20 X is halogen, m, n and k are each 1 or 2, and m+n+k=4.

[0029] According to the present invention, preferably, the general formula of the organosilane is R 1 m SiX n R 2 k , multiple R in the same general fo...

Embodiment 1

[0046] (1) Homopolymerization of propylene In a 500ml dry autoclave, first add 50ml of dry n-hexane, then add 1ml of triethylaluminum with a concentration of 1.8mol / L, a diether-type olefin catalyst (MgCl 2 / TiCl 4 / BMMF, wherein, BMMF is the internal electron donor 9,9-bis(methoxymethyl)fluorene, MgCl 2 、TiCl 4 The mass ratio to BMMF is 73.6:15.2:11.2) 20.0 mg, add 0.2 g of bis-(7-octenyl) dichlorosilane, feed 0.06 g hydrogen, and then feed propylene gas, at 60 ° C, 0.4 Polymerization under MPa pressure for 30 minutes to obtain polypropylene granules, which are directly subjected to the next step of reaction.

[0047] (2) Ethylene-propylene copolymerization

[0048] Vent the propylene gas in the above step (1), and use a vacuum pump to remove the hexane solvent in the polymerization system. The vacuum degree is about 5 mmHg, and the removal time is about 5 minutes. Then feed the ethylene-propylene mixed gas whose molar ratio is 1:1, the polymerization temperature is contr...

Embodiment 2

[0050] According to the method of Example 1, the difference is that after the completion of the polymerization reaction, the gas in the reactor was vented, and then the polymer was transferred to 100°C deionized water to continue the reaction for 30 minutes, and then vacuum-dried at 60°C to obtain a solid Pellet Product Polypropylene Kettle Alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com