A kind of caulking adhesive for thermal insulation engineering of expanded perlite products and its preparation method

A technology of expanded perlite and its preparation method, which is applied in the field of building material joint fillers, can solve the problems of large influence of environmental temperature changes, cracking, low tensile strength, etc., and achieve the solution of unreliable bonding, easy transportation and storage, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

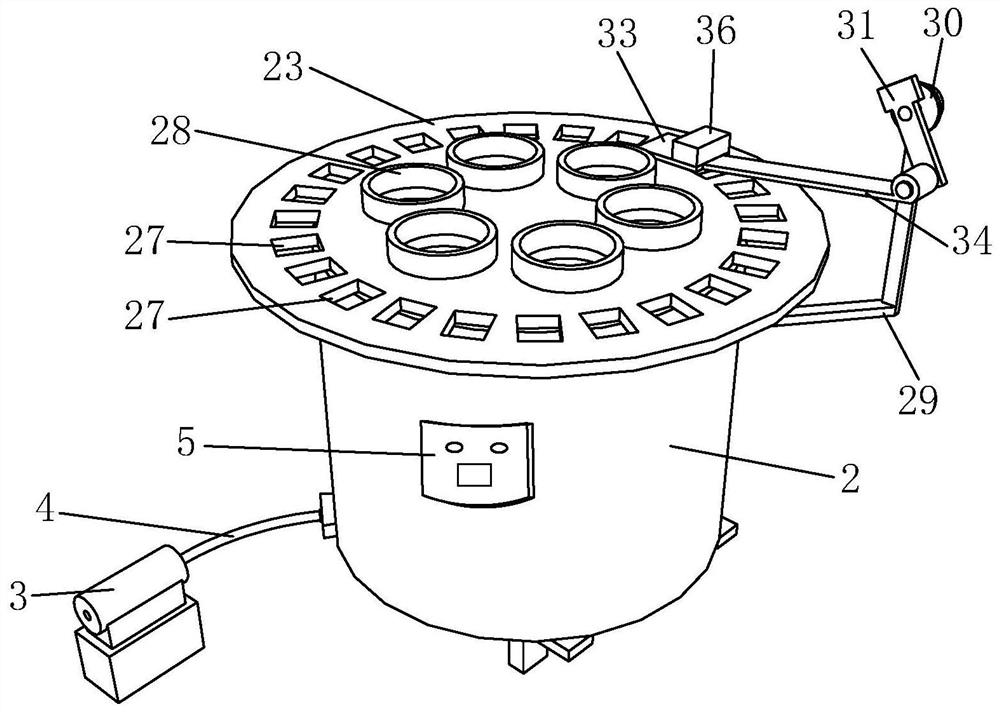

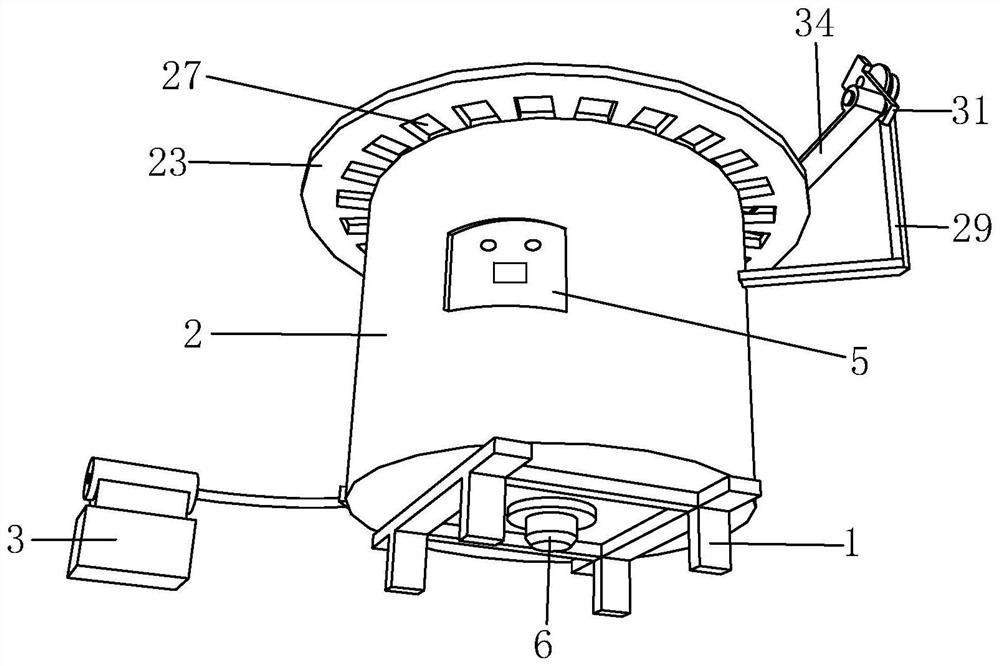

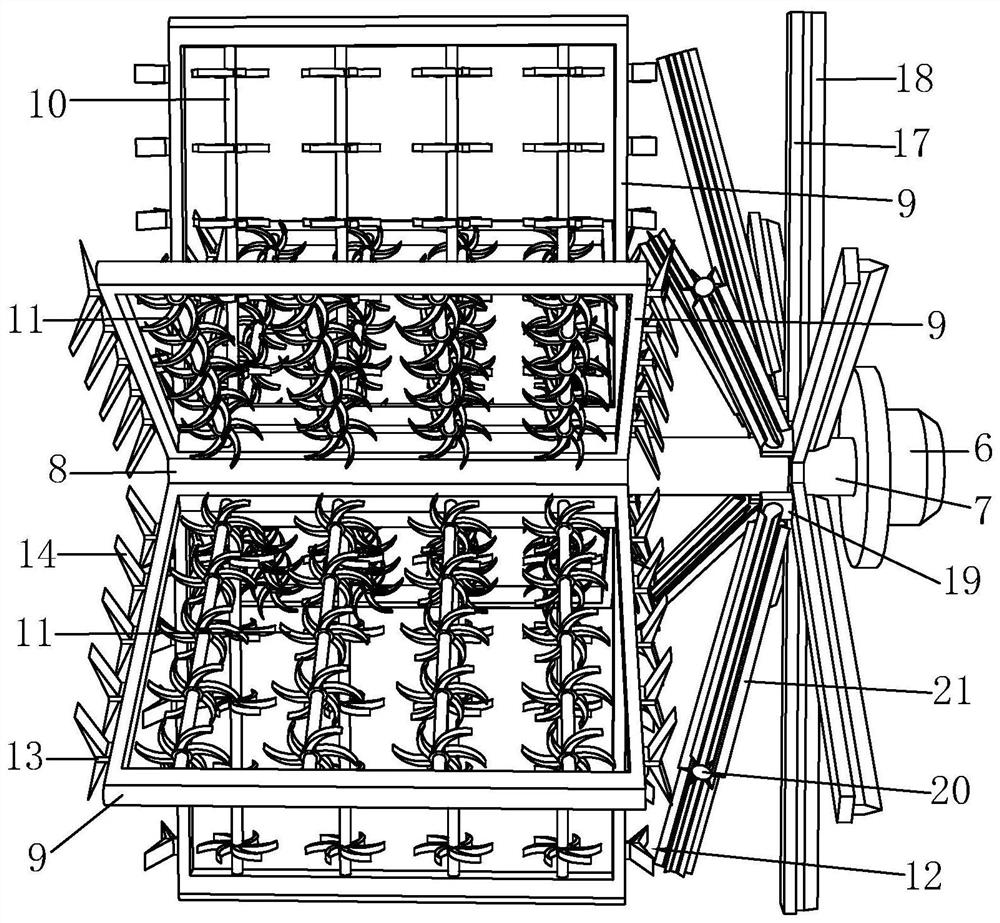

Image

Examples

Embodiment 1

[0057] Weigh 40 parts of 70-90 mesh expanded perlite particles, 20 parts of sodium silicate powder, 20 parts of wollastonite powder, 2 parts of hydroxypropyl methylcellulose, 0.2 part of epoxy fatty acid methyl ester, 0.2 part of polypropylene fiber, Stirring by a stirring device, collecting the finished product, adding 100 parts of water and stirring to obtain a caulking adhesive slurry.

Embodiment 2

[0059] Weigh 40 parts of 90-120 mesh expanded perlite particles, 25 parts of sodium silicate powder, 25 parts of wollastonite powder, 10 parts of bauxite, 1 part of hydroxypropyl methylcellulose, and 2 parts of redispersible latex powder, 0.3 part of epoxidized soybean oil, 0.1 part of polypropylene fiber, and 0.1 part of acrylic resin are stirred by a stirring device, the finished product is collected, and 100 parts of water are added and stirred to obtain a caulking adhesive slurry.

Embodiment 3

[0061] Weigh 30 parts of 70-90 mesh expanded perlite particles, 10 parts of 90-120 mesh expanded perlite particles, 25 parts of gypsum powder, 15 parts of wollastonite powder, 10 parts of heavy calcium, 2 parts of hydroxyethyl methyl cellulose, 2 parts of redispersible latex powder, 0.3 part of epoxy fatty acid methyl ester, 0.2 part of polypropylene fiber, 0.1 part of boric acid, stirred by a stirring device, collected the finished product, added 100 parts of water and stirred to obtain a caulking adhesive slurry.

[0062] Take the performance test data of the seam-filling adhesives prepared in Examples 1-3 and the commercially available seam-filling adhesives under standard laboratories respectively, and the data are shown in Table 1:

[0063]

[0064] Table 1 is the performance test data of the seam-filling adhesives prepared in Examples 1-3 and the commercially available seam-filling adhesives

[0065] It can be seen from Table 1 that the performances of the seam fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com