Composite dry-mixed mortar admixture and preparation method thereof

A dry-mixed mortar and admixture technology, applied in the field of building materials, can solve problems such as bleeding, short setting time, and insufficient compressive strength, and achieve good compatibility, prolong setting time, and precisely control the effect of operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

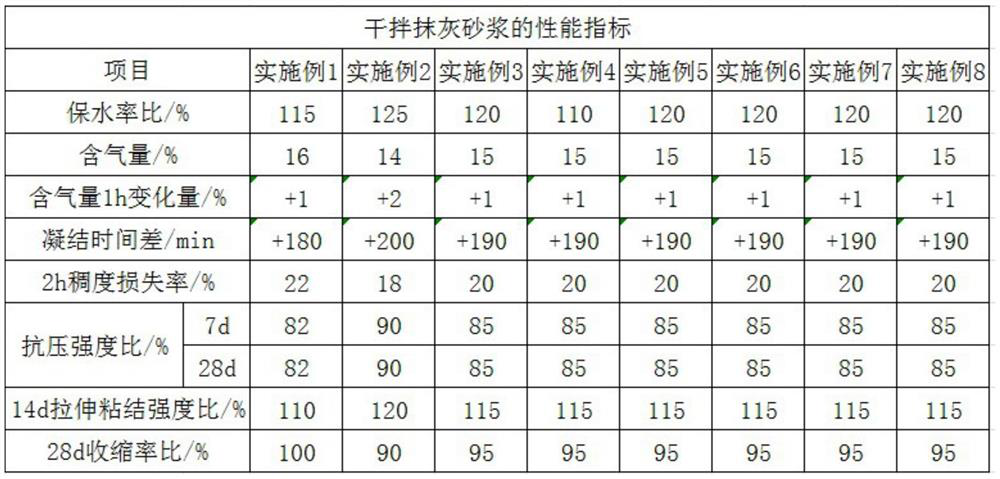

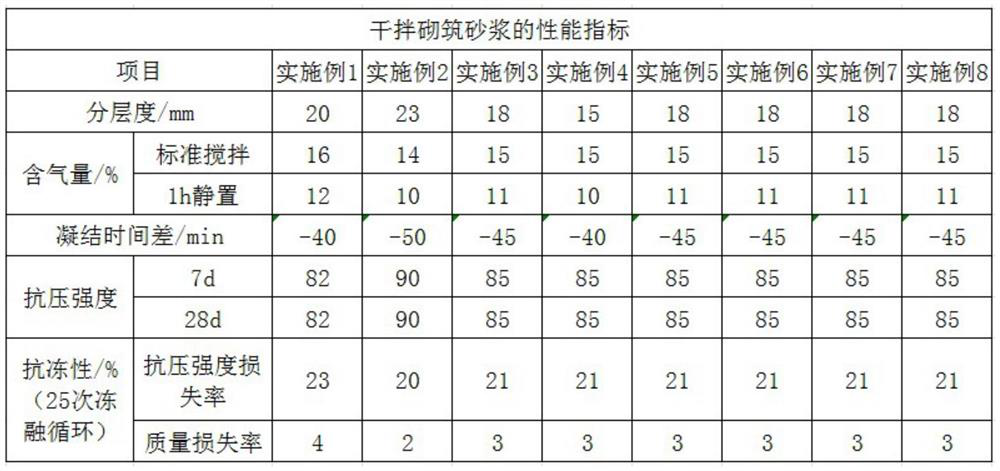

Examples

Embodiment 1

[0021] A composite dry-mixed mortar admixture, consisting of the following components in parts by weight: 100 parts of polyethylene oxide, 180 parts of redispersible latex powder, 13 parts of whiskers, 45 parts of lignosulfonate, dodecane 1 part of sodium sulfate, 10 parts of sodium hexametaphosphate, 8 parts of hydroxyethylene diphosphonic acid, 117 parts of limestone powder, and the above components are prepared according to the following steps:

[0022] Step 1. Weigh 13 parts of whiskers and 117 parts of limestone powder respectively, and put them into a gravity-free mixer to stir until they are evenly mixed;

[0023] Step 2. Weigh 100 parts of polyethylene oxide, 180 parts of redispersible latex powder, 1 part of sodium lauryl sulfate, 10 parts of sodium hexametaphosphate, and 8 parts of hydroxyethylene diphosphonic acid , put into the gravity-free mixer one after another, and stir with the existing mixture until the mixture is uniform;

[0024] Step 3. Weigh 45 parts of ...

Embodiment 2

[0026] A composite dry-mixed mortar admixture and a preparation method thereof, comprising the following components in parts by weight: 100 parts of polyethylene oxide, 220 parts of redispersible latex powder, 15 parts of whiskers, and 55 parts of lignosulfonate , 2 parts of sodium lauryl sulfate, 15 parts of sodium hexametaphosphate, 10 parts of hydroxyethylene diphosphonic acid, 122 parts of limestone powder, and the above components are prepared according to the following steps:

[0027] Step 1. Weigh 15 parts of whiskers and 122 parts of limestone powder respectively, and put them into a gravity-free mixer to stir until they are evenly mixed;

[0028] Step 2, weigh 100 parts of polyethylene oxide, 220 parts of redispersible latex powder, 2 parts of sodium lauryl sulfate, 15 parts of sodium hexametaphosphate, and 10 parts of hydroxyethylene diphosphonic acid , put into the gravity-free mixer one after another, and stir with the existing mixture until the mixture is uniform;...

Embodiment 3

[0031] A composite dry-mixed mortar admixture, consisting of the following components in parts by weight: 100 parts of polyethylene oxide, 200 parts of redispersible latex powder, 14 parts of whiskers, 50 parts of lignosulfonate, dodecane 2 parts of sodium sulfate, 13 parts of sodium hexametaphosphate, 9 parts of hydroxyethylene diphosphonic acid, 120 parts of limestone powder, and the above components are prepared according to the following steps:

[0032] Step 1. Weigh 14 parts of whiskers and 120 parts of limestone powder respectively, and put them into a gravity-free mixer to stir until they are evenly mixed;

[0033] Step 2. Weigh 100 parts of polyethylene oxide, 200 parts of redispersible latex powder, 2 parts of sodium lauryl sulfate, 13 parts of sodium hexametaphosphate, and 9 parts of hydroxyethylene diphosphonic acid , put into the gravity-free mixer one after another, and stir with the existing mixture until the mixture is uniform;

[0034] Step 3. Weigh 50 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com