A method for reuse of glycine production waste water resources

A technology for the production of waste water and glycine, which is applied to chemical instruments and methods, water pollutants, ammonium sulfate, etc., can solve the problems of difficult simultaneous treatment and high pollution concentration, and achieve reduced pollution risk, low construction investment, and improved The effect of removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for recycling waste water resources produced by glycine, said method comprising the following steps:

[0032] (1) The raw water in the collection pond enters the ceramic membrane and is filtered to obtain sewage I;

[0033] (2) Sewage I enters the multi-stage nanofiltration system for separation and concentration. The water produced by the upper membrane is the feed water of the next membrane, and the concentrated water of the lower membrane flows back to the feed water of the upper membrane, and finally contains the concentrated water. The concentrated water of urotropine is reused from the effluent of the first stage membrane to the production workshop, and the produced water is sewage II;

[0034] (3) Sewage II enters the deamination membrane system for deep deamination treatment, and the effluent from the deamination membrane is used as a carbon source for biochemical treatment.

[0035] Preferably, in the step (1), the alkali dosing system controls the pH...

Embodiment 2

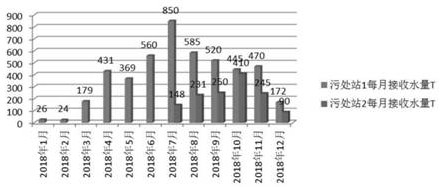

[0042] A company adopts the method of Example 1 to evaporate condensed water from glycine production wastewater, use special inorganic ultrafiltration membranes to remove impurities such as colloids and suspended solids in the water body, and use special multi-level organic membranes to separate and concentrate resource components such as urotropine. The special deamination membrane removes biochemical toxic components such as ammonia nitrogen and then conducts biochemical treatment:

[0043] Step 1) Use the alkali dosing system to control the raw water inlet pH value to 9-10, and use ceramic ultrafiltration membrane to filter;

[0044] Step 2) Use four-stage organic nanofiltration membranes for separation and concentration treatment. The water produced by the upper stage is the water inflow to the next-stage membrane. After urotropine) is reused from the first-stage membrane effluent to the workshop, and the produced water is subjected to subsequent deamination treatment;

...

Embodiment 3

[0052] Using the method of Example 1, the conditions of ceramic membrane, multi-stage nanofiltration system and deamination were screened.

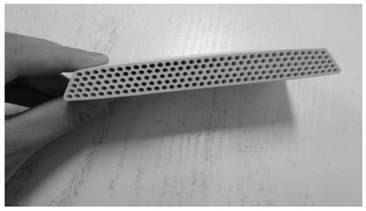

[0053] One, the screening of step (1) ceramic membrane in the method

[0054] Select the wastewater to pass through three kinds of material membranes to verify the pretreatment and filtration effect. The 1# membrane material is ceramic material, the 2# membrane material is polypropylene; the 3# material is polysulfone material, and the wastewater after the membrane is sampled and analyzed. See Table 2 and Figure 3-5 .

[0055] Table 2 Comparison of effects before and after pretreatment

[0056] water sample Before membrane After passing through 1# membrane After passing through 2# film After passing through 3# membrane Suspended matter (mg / L) 53.5 8 20 17 Tropine content (%) 4.9 4.37 4.65 4.52 Turbidity (NTU) 19.2 0.5 1.5 1.2 Chromaticity (PCU) 33.3 11 22 18 SDI 12 3 5 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com