Pressure-resistant corrosion-resistant rubber airbag cloth composite material and preparation method thereof

A rubber airbag and composite material technology, applied in the field of rubber, can solve the problems of chemical corrosion resistance, oil resistance, low product quality, etc., and achieve the effect of strong corrosion resistance and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

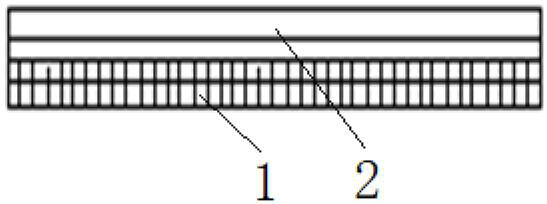

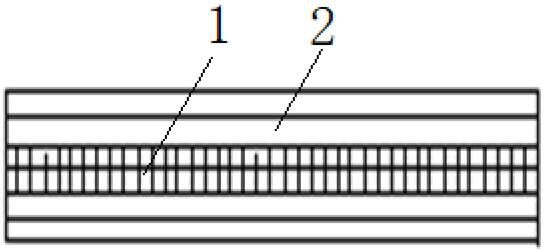

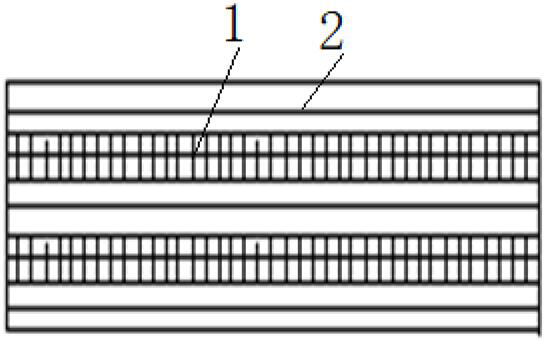

Image

Examples

Embodiment 1

[0073] (1) Add 100 parts of oil-resistant and corrosion-resistant nitrile rubber, 1.5 parts of sulfur, 0.5 parts of tetramethylthiuram disulfide, 3.5 parts of carbon black N330, 5 parts of nano-calcium carbonate and an appropriate amount of plasticizer to the compact Mix in the mixer at 85°C for 20 minutes and discharge; press the oil-resistant and corrosion-resistant pre-vulcanized rubber masterbatch on the open mill or multi-roll calender to form oil-resistant and corrosion-resistant pre-vulcanized rubber sheets. The temperature is 45°C, and the film thickness is 2.6mm.

[0074] (2) With 100 parts of chlorinated butyl rubber with good airtightness, 1.5 parts of sulfur, 0.3 parts of tetramethylthiuram disulfide, 2.5 parts of carbon black N330, 5 parts of nanometer talcum powder and an appropriate amount of plasticizer, add Mix in the internal mixer at 85°C for 20 minutes and discharge; press the oil-resistant and corrosion-resistant pre-vulcanized rubber masterbatch on the op...

Embodiment 2

[0079] (1) Add 100 parts of oil-resistant and corrosion-resistant chlorosulfonated rubber, 1.5 parts of sulfur, 0.3 parts of tetramethylthiuram disulfide, 2.5 parts of carbon black N220, 3.5 parts of nano-silica and an appropriate amount of plasticizer. Mix in the internal mixer at 90°C for 25 minutes and discharge; press the oil-resistant and corrosion-resistant pre-vulcanized rubber masterbatch on the open mixer or multi-roll calender to form oil-resistant and corrosion-resistant pre-vulcanized rubber sheets. The sheet temperature was 45°C, and the film thickness was 2.8 mm.

[0080] (2) 100 parts of airtight good brominated butyl rubber, 1.5 parts of sulfur, 0.25 parts of tetramethylthiuram disulfide, 2.5 parts of carbon black N220, 3.5 parts of nanometer nano talcum powder and an appropriate amount of plasticizer, Put it into the internal mixer and mix at 90°C for 25 minutes to discharge the material; press the oil-resistant and corrosion-resistant pre-vulcanized rubber ma...

Embodiment 3

[0085] (1) Add 100 parts of oil-resistant and corrosion-resistant nitrile rubber, 1.5 parts of sulfur, 0.5 parts of tetramethylthiuram disulfide, 3.5 parts of carbon black N330, 5 parts of nano-calcium carbonate and an appropriate amount of plasticizer to the compact Mix in the mixer at 85°C for 20 minutes and discharge; press the oil-resistant and corrosion-resistant pre-vulcanized rubber masterbatch on the open mill or multi-roll calender to form oil-resistant and corrosion-resistant pre-vulcanized rubber sheets. The temperature is 50°C, and the film thickness is 2.7mm.

[0086] (2) With 100 parts of bromobutyl rubber with good airtightness, 1.5 parts of sulfur, 0.3 parts of tetramethylthiuram disulfide, 2.5 parts of carbon black N330, 5 parts of nano-calcium carbonate and an appropriate amount of plasticizer, add Mix in the internal mixer at 85°C for 20 minutes and discharge; press the oil-resistant and corrosion-resistant pre-vulcanized rubber masterbatch on the open mixer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com