Scrubber apparatus having integrated venturi

A washing device and venturi technology, applied in the direction of muffler device, exhaust device, gas channel, etc., can solve the problem of difficult to expand cylindrical Venturi pipes, increase in size or volume or weight, decrease in handling or installation, etc. problems, to achieve the effect of increasing the effectiveness of dust collection, minimizing the restriction of installation space, and preventing the increase of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

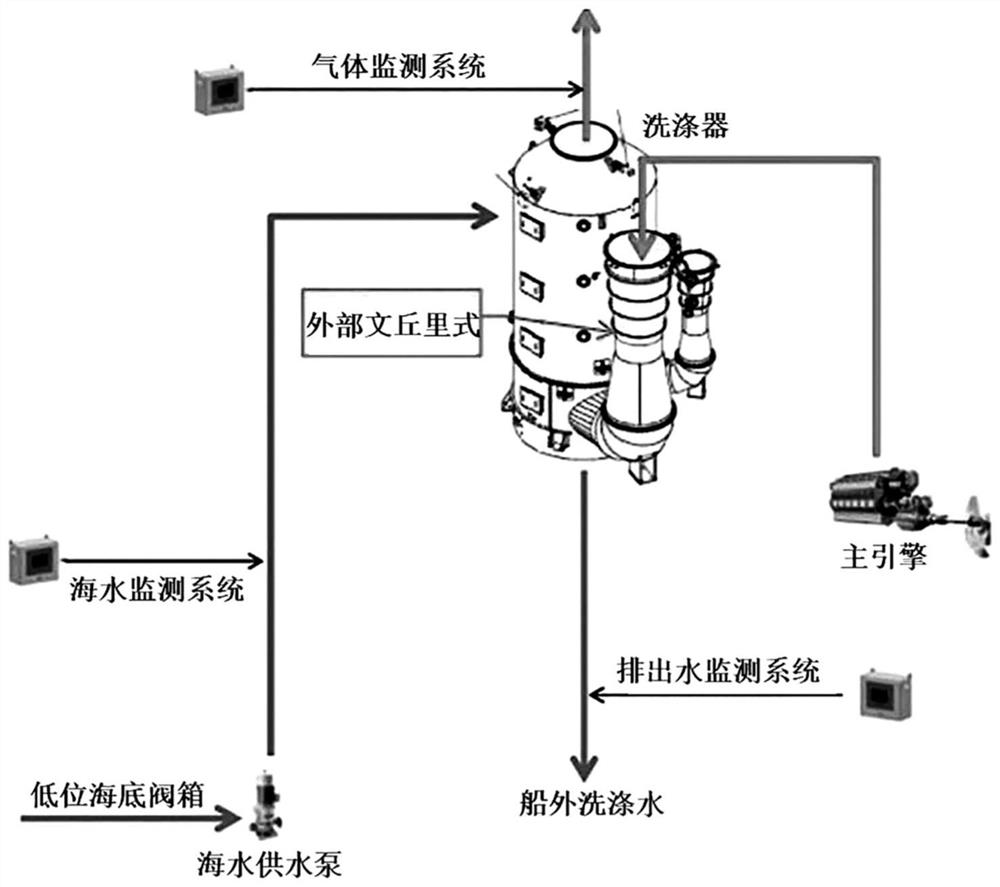

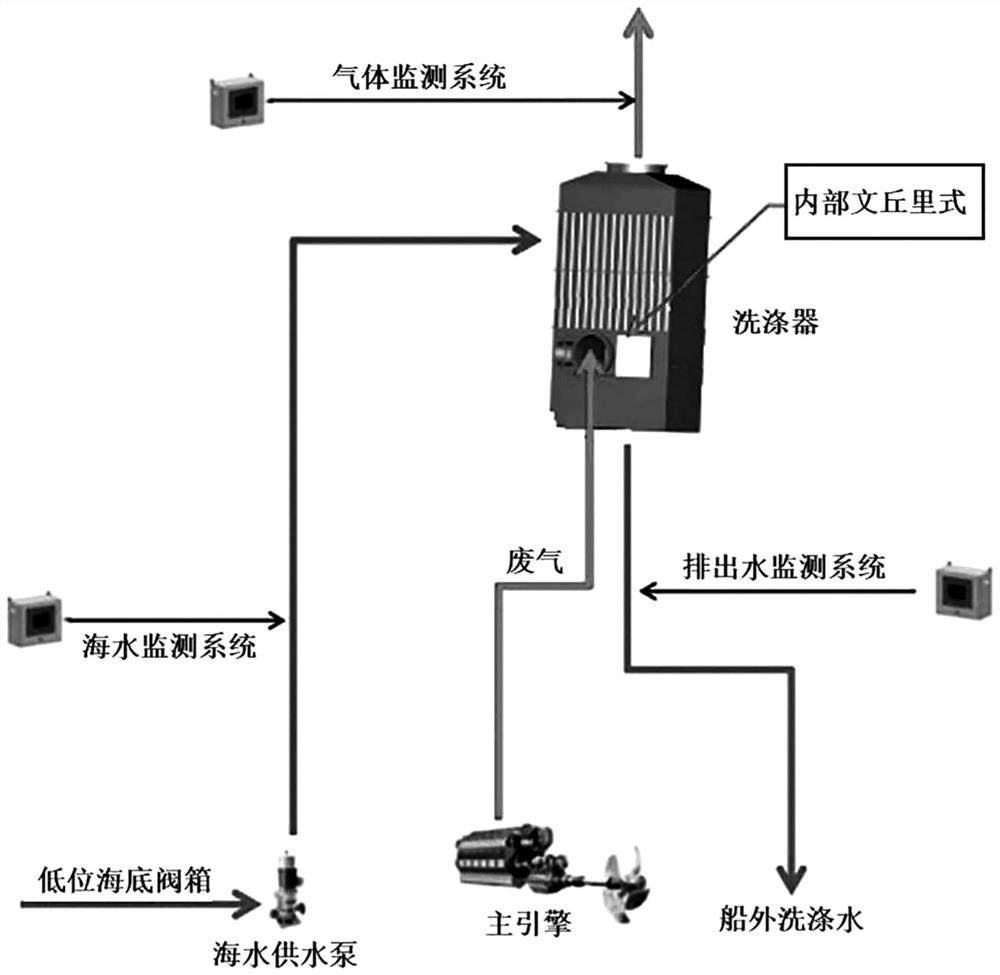

[0065] First, refer to image 3 An example of a washer module system to which a Venturi-integrated washer of the present invention is applied will be described.

[0066] in, image 3 A schematic configuration diagram showing a washer module system as an example of a Venturi-integrated washing apparatus to which the present invention is applied.

[0067] As shown in the figure, the scrubber module system plays the following role, that is, the Venturi integrated scrubber device of the present invention is connected to the exhaust pipe of the main engine of the ship, and the exhaust gas such as sulfur oxides in the exhaust gas discharged from the engine (Sox) gaseous substances and harmful particulate matter such as dust or fine dust come into contact with the washing water, condense and collect, thereby removing them.

[0068] In this case, the scrubbing device is connected to a gas monitoring system (GAS MONITORING SYSTEM), which is used to detect the scrubbed waste gas disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com