A kind of reinforced flame retardant powder for sealant and its preparation method and application

A technology of sealant and flame retardant powder, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., and can solve problems such as poor compatibility, high price, and unfavorable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

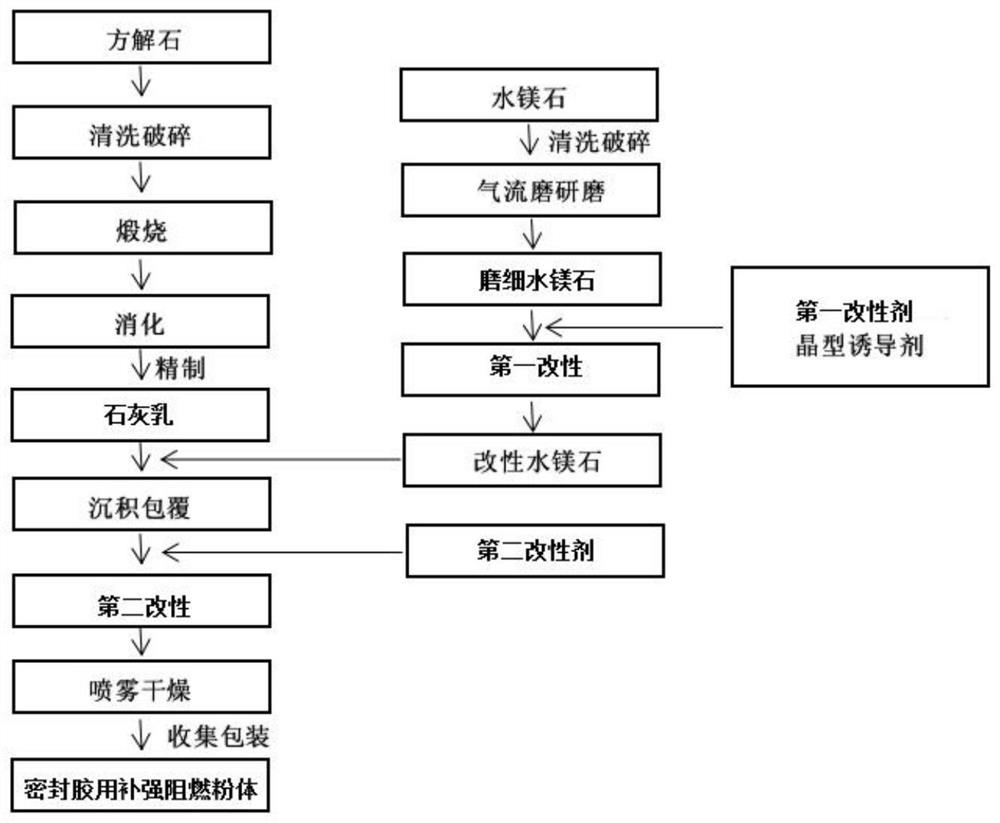

[0024] The invention provides a method for preparing a reinforced flame-retardant powder for sealants, comprising the following steps:

[0025] Grinding brucite to obtain finely ground brucite;

[0026] After mixing the ground brucite, the first modifier and the crystal form inducer, the first modification is performed to obtain the modified brucite; the first modifier is 3-aminopropyltrimethoxy One or more of methoxysilane, 3-methacryloxypropyltrimethoxysilane and ethylenediaminetetraacetic acid;

[0027] mixing the modified brucite and milk of lime for deposition and coating to obtain a coating liquid;

[0028] Immediately add a second modifier to the coating liquid to carry out the second modification to obtain the reinforced flame retardant powder for the sealant; the second modifier is aluminate, stearic acid One or more of sodium, hydrogenated rosin and sodium dodecylbenzenesulfonate.

[0029] The present invention grinds brucite to obtain finely ground brucite;

[0...

Embodiment 1

[0075] Brucite (mass content of magnesium hydroxide is 88%) is washed and broken, and ground to 6000 mesh by jet mill to obtain finely ground brucite;

[0076] 3-Aminopropyltrimethoxysilane, EDTA and MgSO 4 Mix evenly with a small amount of water and add it to a high-speed mixer together with ground brucite powder. Under the conditions of 2000r / min and 80°C, carry out the first modification for 25 minutes. After modification, pass through a 300-mesh sieve to obtain modified water. Magnesite is reserved; the quality of 3-aminopropyltrimethoxysilane is 1% of the mass of ground brucite, EDTA and MgSO 4 Each is 0.01% of the mass of ground brucite;

[0077] Calcite (the mass content of calcium carbonate is 97%) is cleaned and crushed, calcined at 1100° C. to obtain quicklime, and water with 5 times the quality of quicklime is added for digestion. The stirring speed during digestion is 60 r / min. After the digestion is completed, the digested feed liquid is passed through After bei...

Embodiment 2

[0091] Brucite (magnesium hydroxide mass content is 89%) is washed and broken, and ground to 6000 mesh by jet mill to obtain finely ground brucite;

[0092] Mix 3-methacryloyloxypropyltrimethoxysilane and glucose with a small amount of water and add them to the high-speed mixer together with ground brucite. Under the conditions of 2500r / min and 110℃, the first Modified for 20 minutes, passed through a 300-mesh sieve after modification to obtain modified brucite for subsequent use, wherein the quality of 3-methacryloxypropyltrimethoxysilane is 1% of the quality of ground brucite, and the quality of glucose is 0.015% of the mass of ground brucite powder;

[0093] Calcite (calcium carbonate mass content is 97%) is washed and crushed, calcined into quicklime at 1100°C, and then digested by adding water with 5 times the quality of quicklime. The stirring speed during digestion is 60r / min. After being separated and refined by the stage hydrocyclone, let it stand and cool down to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com