Preparation method of self-repairing carbon nanotube-cationic waterborne polyurethane electromagnetic shielding composite material

An electromagnetic shielding material, water-based polyurethane technology, applied in the field of preparation of polymer-based functional composite materials, can solve problems such as performance degradation and failure, and achieve the effects of improving use stability, reducing life cycle costs, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

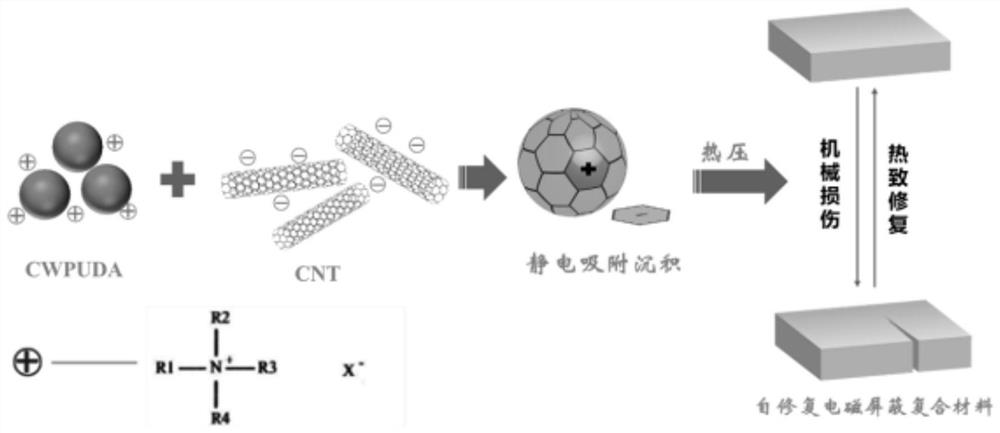

[0066] The process steps adopt:

[0067] (1) Uniformly disperse carbon nanotubes (CNT) into water with a cell ultrasonic breaker to prepare a CNT aqueous dispersion;

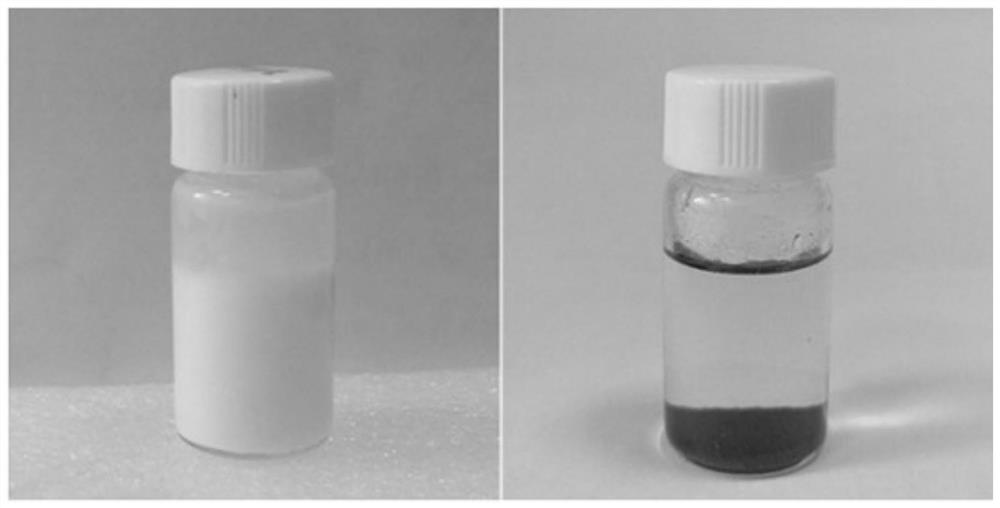

[0068] (2) Blend the self-healing cationic waterborne polyurethane (CWPUDA) emulsion and the CNT aqueous dispersion in a certain weight ratio (see Table 1 for the specific formula), and use the electrostatic adsorption interaction between ions with different charges to coat the CNT on the On the surface of CWPUDA particles, suction filter and dry.

[0069] (3) The composite particles obtained in step (2) were hot-pressed at 120°C for 10 min to prepare the self-healing electromagnetic shielding composite material.

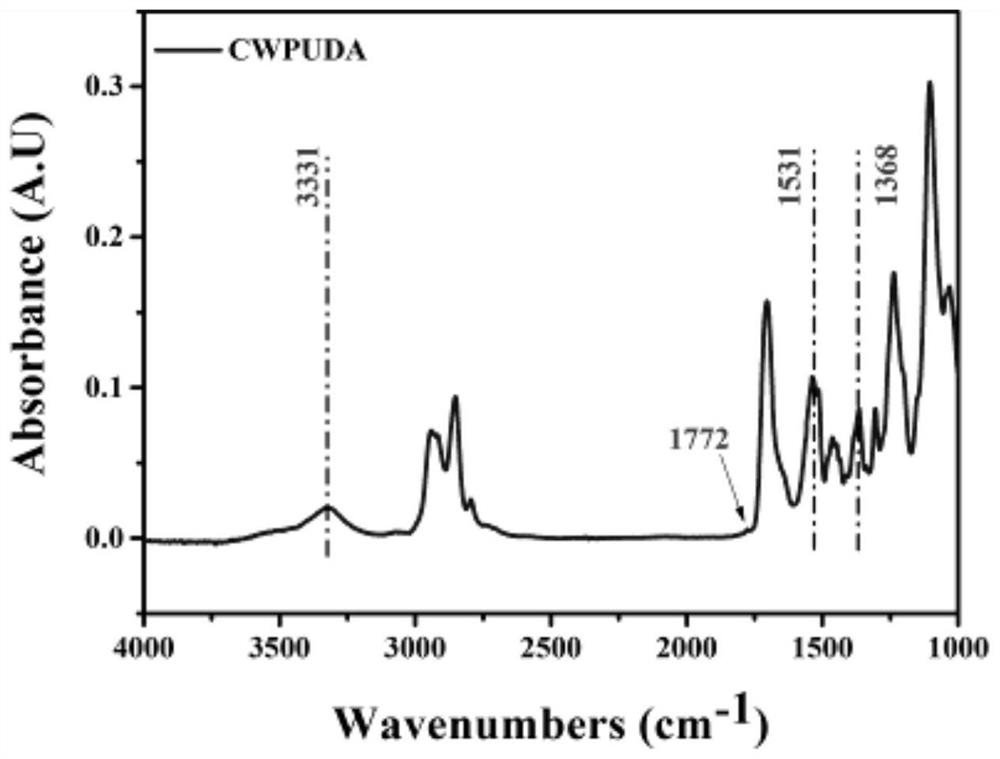

[0070] Wherein, the concrete preparation process of described CWPUDA emulsion is:

[0071] (A) Add 4.92 g of furfurylamine and 5.99 g of hydroxymethyldioxolanone into a flask, heat to 60°C with stirring, and react at constant temperature for 3 h to prepare diols with furan groups.

[0072] (B) Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com