Composite admixture for shotcrete

A composite admixture and sprayed concrete technology, which is applied in the field of concrete admixtures, can solve the problems of concrete strength influence, low homogeneity level, water-cement ratio increase, etc., achieve reinforcement, increase hydration speed, and maintain moisture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

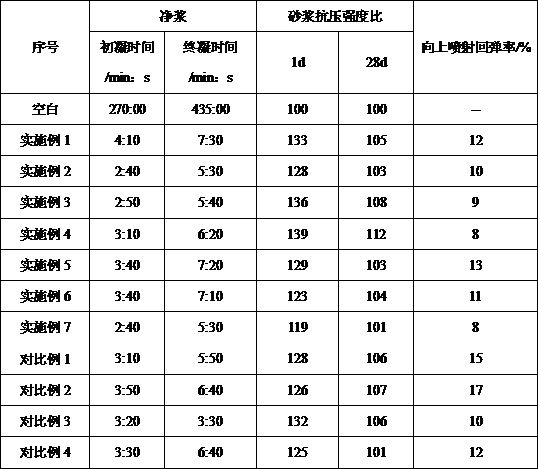

Examples

Embodiment 1

[0017] A composite admixture for shotcrete is composed of the following parts by weight: 5 parts of polycarboxylate water reducer, 5 parts of alcohol ether sulfosuccinic acid monoester disodium salt, 2 parts of tackifier, and 3 parts of ammonium nitrate , 5 parts of alcohol amine carboxylate, 0.1 part of sodium dodecylbenzenesulfonate, 0.01 part of silicone defoamer, 30 parts of superfine fly ash.

[0018] The tackifier is composed of modified starch and polyvinyl alcohol.

[0019] The alcohol amine carboxylate is an oxalate ester of triisopropanolamine.

Embodiment 2

[0021] A composite admixture for shotcrete is composed of the following parts by weight: 20 parts of polycarboxylate water reducer, 1 part of alcohol ether sulfosuccinic acid monoester disodium salt, 8 parts of tackifier, and 1 part of ammonium nitrate , 10 parts of alcohol amine carboxylate, 0.01 part of sodium dodecylbenzenesulfonate, 0.1 part of organic silicon defoamer, and 80 parts of superfine fly ash.

[0022] The tackifier is composed of acrylonitrile grafted starch and polyvinyl alcohol.

[0023] The alcohol amine carboxylate is diethanol monoisopropanolamine maleate.

Embodiment 3

[0025] A composite admixture for shotcrete is composed of the following parts by weight: 12 parts of polycarboxylate water reducer, 4 parts of alcohol ether sulfosuccinic acid monoester disodium salt, 6 parts of tackifier, and 2 parts of ammonium nitrate , 8 parts of alcohol amine carboxylate, 0.04 part of sodium dodecylbenzenesulfonate, 0.02 part of silicone defoamer, 50 parts of superfine fly ash.

[0026] The tackifier is composed of modified starch and polyvinyl alcohol.

[0027] The thickening agent is composed of modified tapioca starch and polyvinyl alcohol with molecular weight between 80000-10000.

[0028] The alcohol amine carboxylate is triisopropanolamine maleate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com