Porous lithium manganate positive electrode material and preparation method thereof

A positive electrode material, porous lithium manganate technology, applied in positive electrodes, chemical instruments and methods, manganate/permanganate, etc., can solve the problem of poor cell rate performance, affecting the expansion of lithium manganate market segments, etc. problem, to achieve high energy density, excellent rate performance, and the effect of being conducive to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

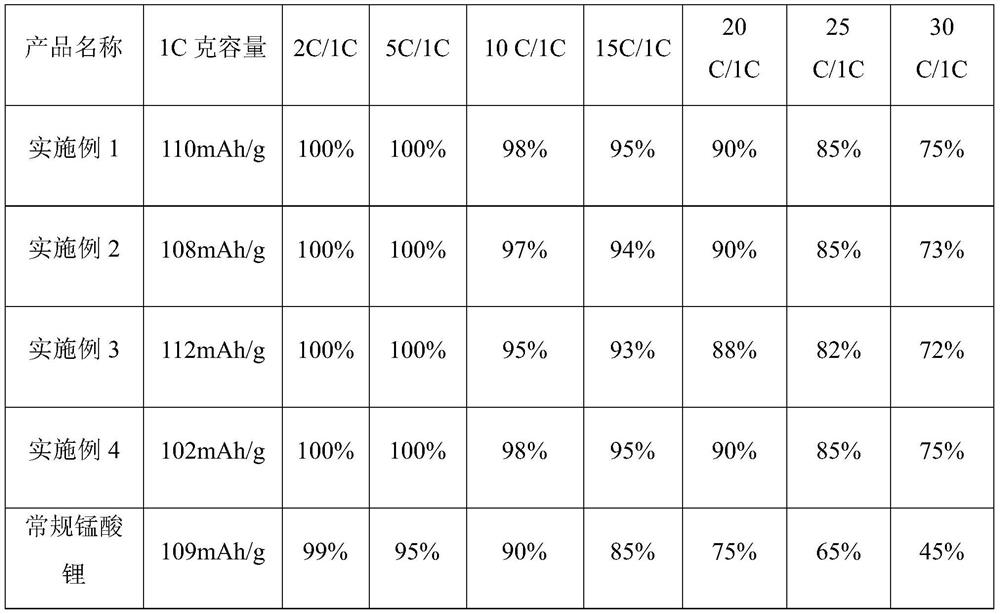

Embodiment 1

[0016] The preparation formula is LiMn 1.95 m 0.05 o 4 High rate lithium manganese oxide cathode material.

[0017] Lithium carbonate, manganese source (EMD) and additive Al are fully mixed according to their elemental molar ratio of 1.06:1.95:0.05, and then kept in a box furnace at a pressure of 10MPa under an oxygen atmosphere and kept at 800°C for 20 hours. After firing at high temperature, the furnace body keeps the oxygen pressure and cools down naturally, stops maintaining the pressure when it is below 500°C, turns on the furnace and cools down to normal temperature naturally when it is below 300°C, and then sieves to obtain the porous lithium manganate cathode material.

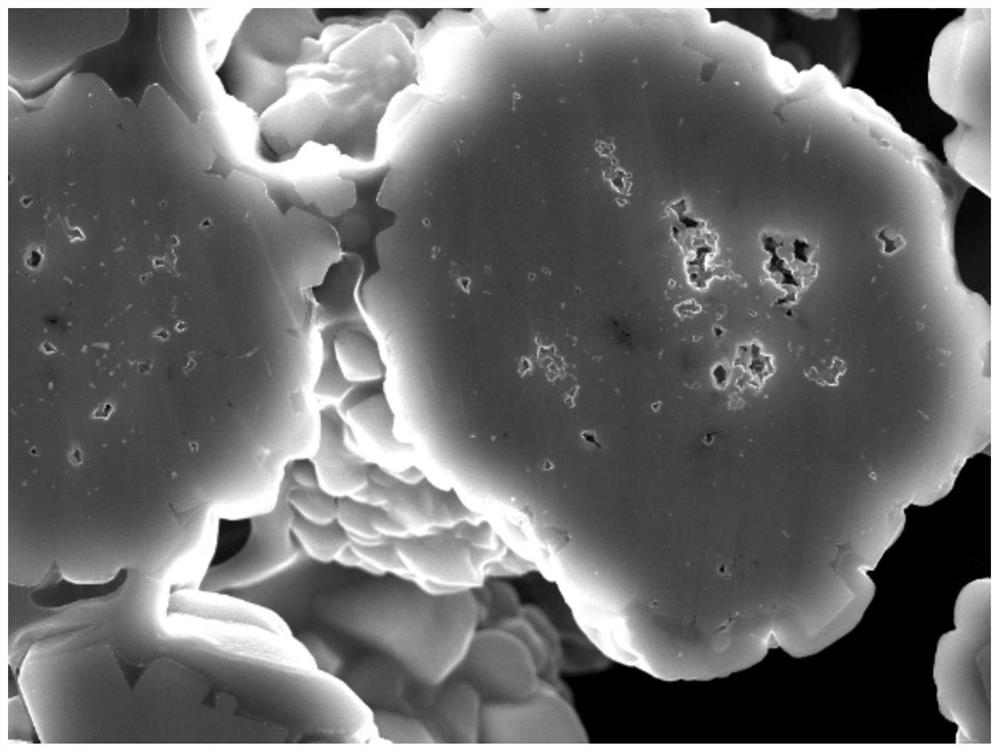

[0018] Depend on figure 1 It can be seen from the scanning electron microscope image in the figure that the internal pores of the obtained porous lithium manganese oxide particles increase significantly.

Embodiment 2

[0020] The preparation formula is LiMn 1.93 m 0.07 o 4 High rate lithium manganese oxide cathode material.

[0021] Lithium carbonate, manganese source (EMD) and additive Mg are fully mixed according to their elemental molar ratio of 1.05:1.93:0.07, and then kept in a box furnace under an oxygen atmosphere at a pressure of 8MPa and kept at 780°C for 18 hours. After firing at high temperature, the furnace body keeps the oxygen pressure and cools down naturally, stops maintaining the pressure when it is below 500°C, turns on the furnace and cools down to normal temperature naturally when it is below 300°C, and then sieves to obtain the porous lithium manganate cathode material.

Embodiment 3

[0023] The preparation formula is LiMn 1.97 m 0.03 o 4 High rate lithium manganese oxide cathode material.

[0024] Lithium carbonate, manganese source (EMD) and additive Nb are fully mixed according to their elemental molar ratio of 1.06:1.97:0.03, and then kept at 850°C for 15 hours in a box furnace under an oxygen atmosphere at a pressure of 10MPa. After firing at high temperature, the furnace body keeps the oxygen pressure and cools down naturally, stops maintaining the pressure when it is below 500°C, turns on the furnace and cools down to normal temperature naturally when it is below 300°C, and then sieves to obtain the porous lithium manganate cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com