Precise traceless forming assembly line of automobile assembly

A technology of automobile components and assembly line, which is applied in the direction of used abrasive processing devices, abrasives, manufacturing tools, etc., can solve the problems of not forming an overall assembly line production, multiple production equipment, separation, etc., and achieve strong correlation between equipment and structure Compactness, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

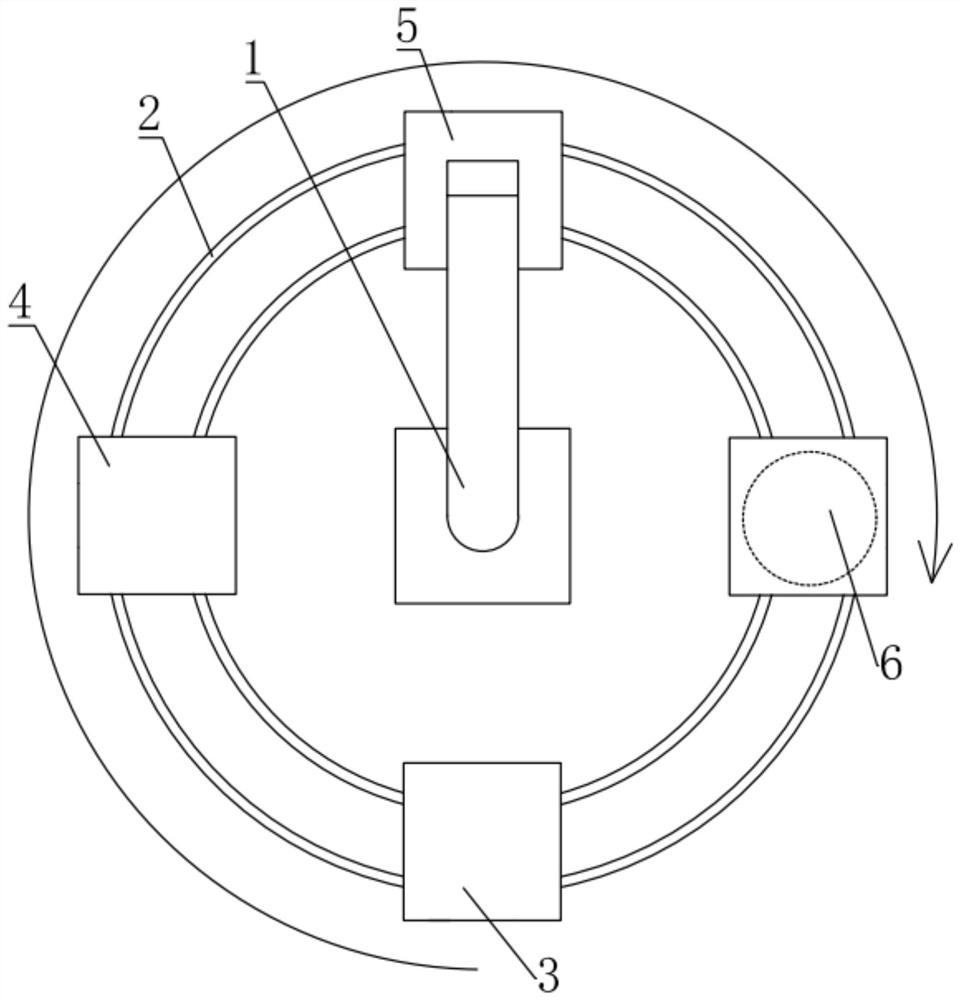

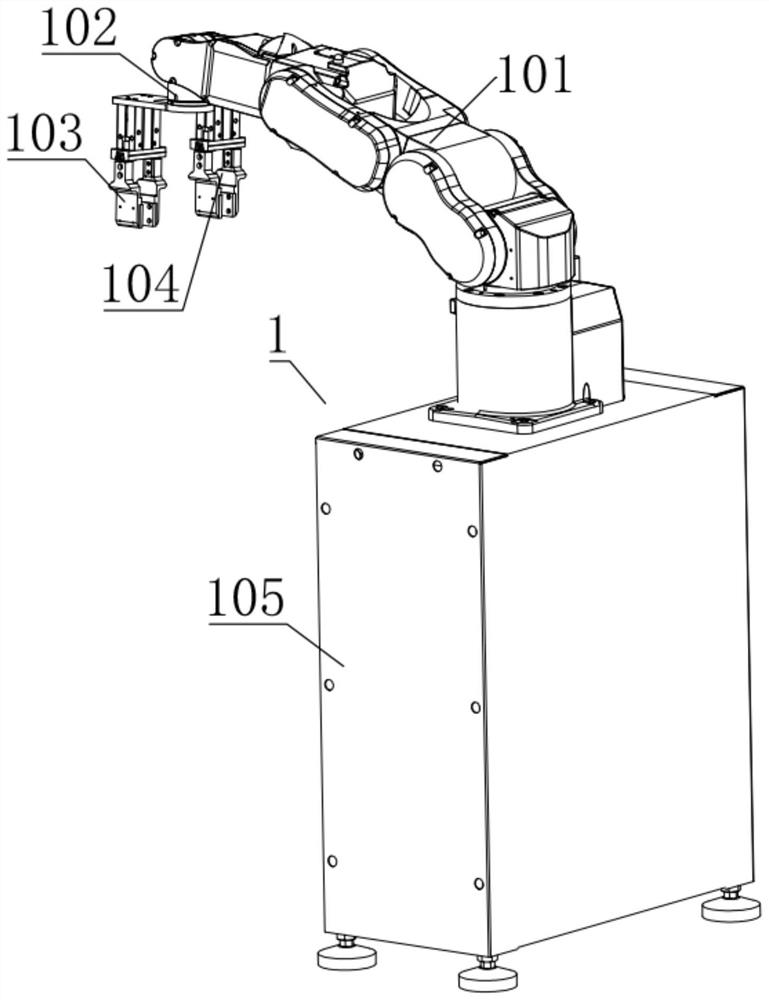

[0045] Such as figure 1 , 2 The precision seamless forming line of automobile components shown includes a transfer manipulator 1, a circular track 2, an injection mold unit 3, a shaping die unit 4, a punching unit 5 and a shot blasting surface treatment unit 6, and the transfer manipulator 1 is set In the middle position of the circular track 2, the injection mold unit 3, the shaping mold unit 4, the punching unit 5 and the shot blasting surface treatment unit 6 are all arranged on the circular track 2, and the injection mold unit 3, the shaping mold unit 4. The punching unit 5 and the shot blasting surface treatment unit 6 are arranged in a circular array centered on the transfer manipulator 1. Carry out the transshipment of automobile injection molded parts sequentially between the surface treatment unit 6, described transshipment manipulator 1 comprises mechanical arm 101, turntable one 102, gripper cylinder one 103, gripper cylinder two 104 and manipulator base 105, descr...

Embodiment 2

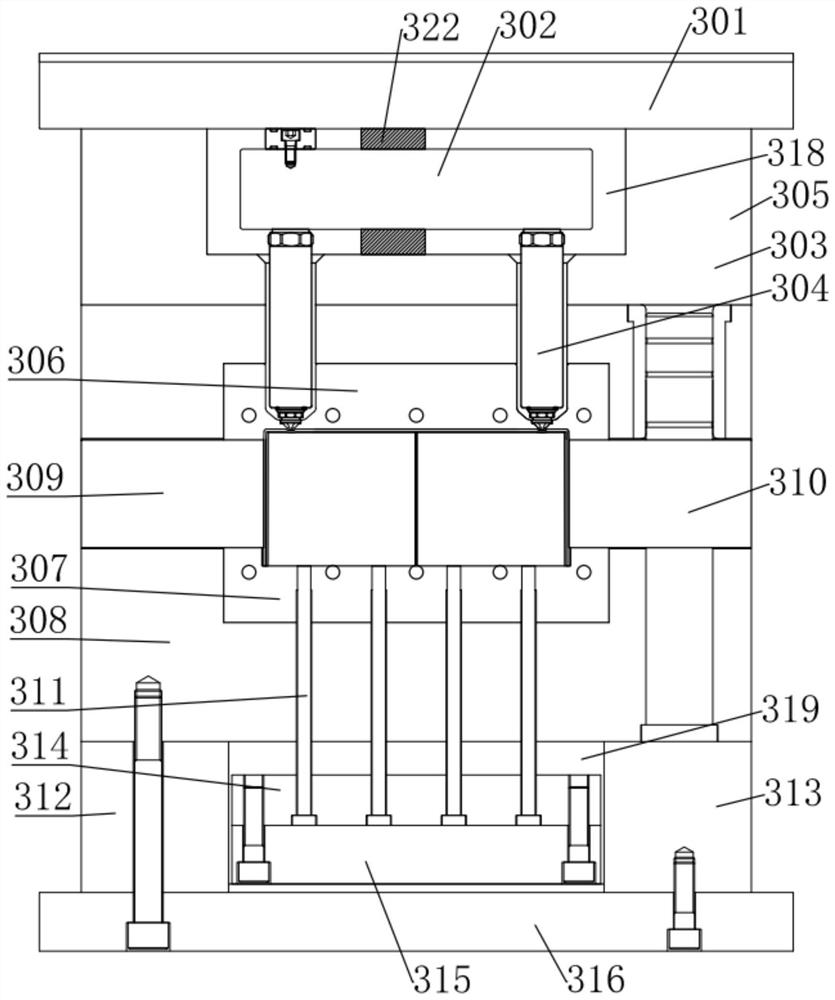

[0047] Such as Figure 3-9The injection mold unit 3 shown includes an upper fixing plate 301, a manifold 302, a hot runner plate 303, a set of hot runner cores 304, a female template 305, a female mold core 306, a male mold core 307, a male template 308, and side templates. One 309, two side templates 310, one set of ejector pins 311, one mold foot 312, two mold feet 313, upper ejector plate 314, lower ejector plate 315 and lower fixing plate 316, the upper fixing plate 301, hot runner plate 303, the female template 305, the male template 308, the first mold foot 312, the second mold foot 313 and the lower fixing plate 316 are arranged in sequence from top to bottom, and the upper fixing plate 301 is provided with a main glue inlet 317, so The main glue inlet 317 communicates with the splitter plate 302, the upper end of the hot runner plate 303 is provided with a cavity 318, the splitter plate 302 is arranged in the cavity 318, the set of hot runner cores 304 and the splitter...

Embodiment 3

[0052] Such as Figure 10 , 11 The shown shaping mold unit 4 includes a shaping support platform 401, a shaping jig support frame 402, a shaping support base 403, an upper stamping head lifting assembly 404, an upper backing plate 405, an upper stamping head 406, a horizontal rotation assembly 407, and a lower stamping seat One 408 and lower stamping seat two 409, the shaping support platform 401 is arranged on the upper end of the shaping support base 403, the lower end of the shaping fixture support frame 402 is fixedly arranged on the upper end surface of the shaping supporting platform 401, the The upper punch head lifting assembly 404 is arranged on the shaping fixture support frame 402, the upper backing plate 405 is arranged on the upper punch head lifting assembly 404, and the upper punch head lifting assembly 404 can drive the upper backing plate 405 to move vertically , the upper stamping head 406 is arranged on the upper backing plate 405, the lower stamping seat o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com