Alkaline residue recycling method, product and application

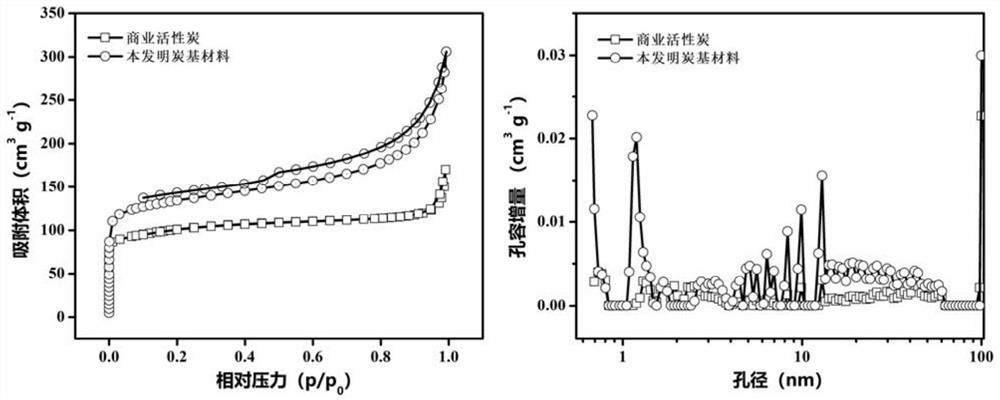

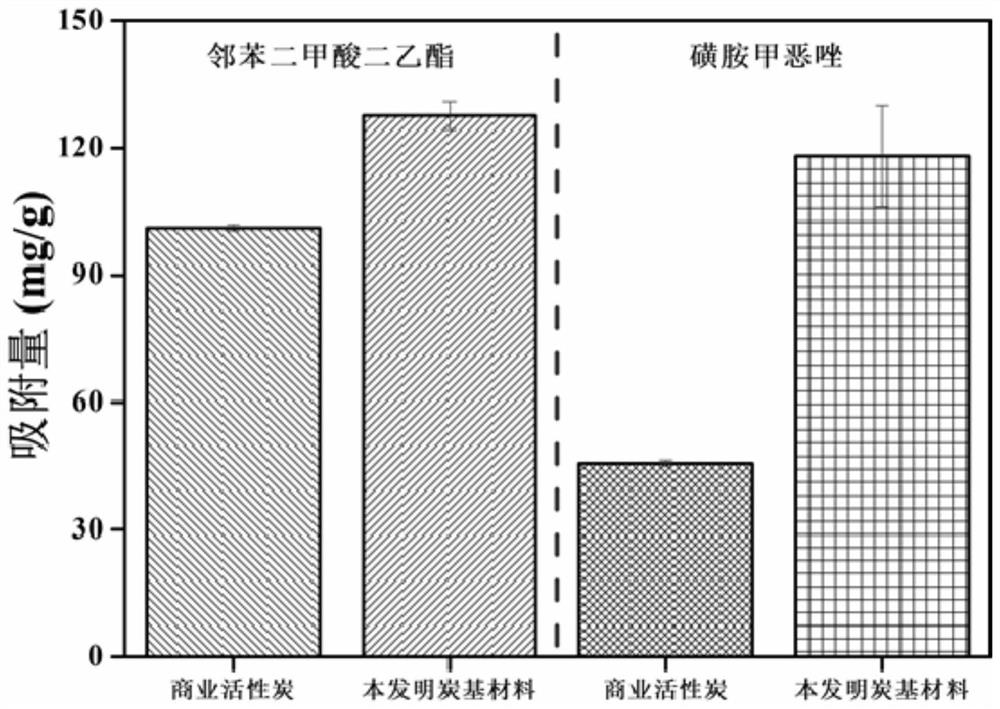

A recycling and alkali slag technology, applied in the field of solid waste recycling, can solve problems such as unfriendly production process, impact on application, high price, etc., to avoid secondary environmental pollution problems, excellent quality transmission channels, and efficient resources effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The method for recycling alkali slag provided in this embodiment includes the following steps:

[0048] The alkali slag and the agricultural, forestry and animal husbandry biomass corncobs were placed in 110°C for drying, crushed, and prepared into the alkali slag powder and the agricultural, forestry and animal husbandry biomass powder, and the 10g of the alkali slag powder and 5g of the agricultural, forestry and animal husbandry biomass corncob powder were mixed evenly (mass ratio 2:1) to obtain a mixture. Put the mixture in a corundum crucible, put it into a tubular muffle furnace, raise the temperature to 900°C at a rate of 5°C / min, keep it for 1h, and then cool it down to room temperature. The black residue was crushed and placed in a beaker. Use hydrochloric acid solution, ultrapure water, sodium carbonate solution, hydrochloric acid solution, hydrofluoric acid solution, ultrapure water to clean in sequence, specifically: filter and clean by heating and stirring...

Embodiment 2

[0052] The method for recycling alkali slag provided in this embodiment includes the following steps:

[0053] The alkali slag and the agricultural, forestry and animal husbandry biomass sawdust were dried at 110°C and crushed to prepare the alkali slag powder and the agricultural, forestry and animal husbandry biomass powder, and the 2.5g alkali slag powder and 5g of the agricultural, forestry and animal husbandry biomass powder were mixed evenly (mass ratio: 0.5:1), a mixture was obtained. Put the mixture in a corundum crucible, then put the corundum crucible into a tubular muffle furnace, raise the temperature to 800°C at a rate of 1°C / min, keep it for 0.5h, then cool down to room temperature, and the nitrogen flow rate in the whole process is 400mL / min , take out the gray-black residue and pulverize it, and place it in a beaker. Use hydrochloric acid solution, ultrapure water, sodium carbonate solution, hydrochloric acid solution, hydrofluoric acid solution, ultrapure wat...

Embodiment 3

[0055] The method for recycling alkali slag provided in this embodiment includes the following steps:

[0056] The alkali slag and agricultural, forestry and animal husbandry biomass corncobs were placed in 110°C to dry and crush, respectively, to prepare alkali slag powder and agricultural, forestry and animal husbandry biomass powder, and the 15g of alkali slag powder and 5g of agricultural, forestry and animal husbandry biomass powder were mixed evenly (mass ratio: 3:1), a mixture was obtained. Put the mixture in a corundum crucible, then put the corundum crucible into a tubular muffle furnace, raise the temperature to 600°C at a rate of 10°C / min, keep it for 5h, then cool down to room temperature, the nitrogen flow rate in the whole process is 50mL / min, Take out the gray-black residue and pulverize it, and place it in a beaker. Use hydrochloric acid solution, ultrapure water, sodium carbonate solution, hydrochloric acid solution, hydrofluoric acid solution, ultrapure wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com