High-precision driving mechanism for nuclear reactor control rod

A technology for nuclear reactors and driving mechanisms, applied in the control of nuclear reactions, reactors, nuclear engineering, etc., can solve problems such as difficulty, inability to shut down the reactor in an emergency, and cumbersome control methods, achieve low requirements for parts processing and assembly precision, and improve economic benefits And social benefits, flexible and adjustable effect of falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

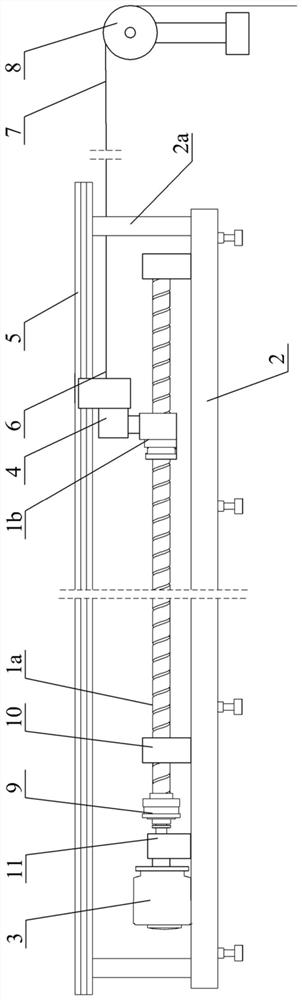

[0028] figure 1As shown, a specific embodiment of the present invention is a high-precision driving mechanism for nuclear reactor control rods, which is characterized in that: the two ends of the screw 1a of the ball screw pair are installed on the base 2 through the bearing housing 10, and the screw 1a The left end of the motor 3 is connected to the output shaft of the motor 3 through a coupling 9, and the top of the nut 1b of the ball screw pair is fixedly equipped with an electromagnetic attraction mechanism 4; the two sides of the base 2 are provided with pillars 2a, and the pillars 2a on both sides The top is connected with a linear slide rail 5 made of stainless steel, and the electromagnetic attraction mechanism 4 is opposite to the magnetic slider 6 of the linear slide rail 5. Go through the right pillar 2a, and then bypass the fixed pulley 8 to connect with the control rods of the nuclear reactor; the motor 3 and the electromagnetic attraction mechanism 4 are both ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com