Wallpaper paving method

A technology of wallpaper and paving, applied in the direction of surface pretreatment bonding method, adhesive type, polyurea/polyurethane adhesive, etc., can solve the problem of inapplicable long-term damp wall environment, shortened service life of wallpaper, Problems such as loose fiber structure, to achieve significant antibacterial and bactericidal properties, excellent water resistance, and accelerated separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

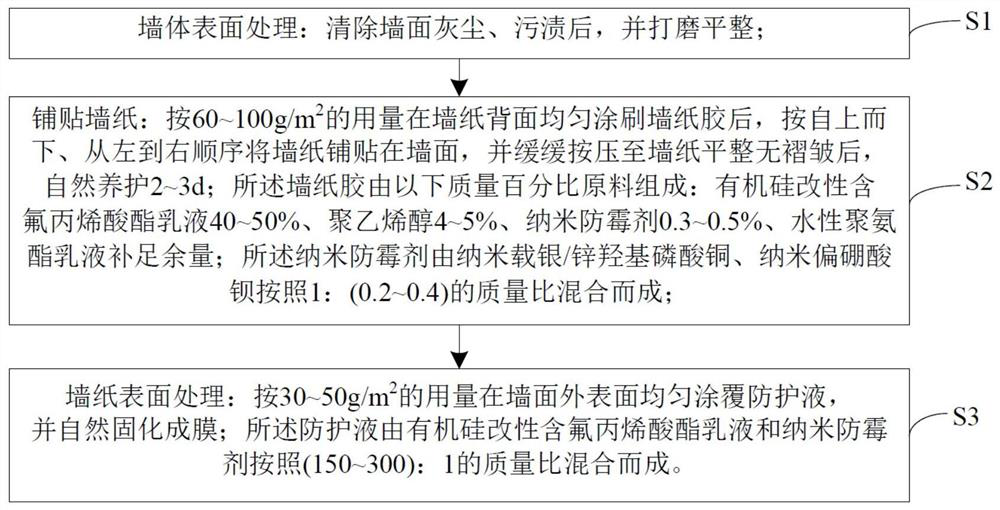

[0026] A method for laying wallpaper, comprising the steps of:

[0027] S1: Preparation of silicone-modified fluorine-containing acrylate emulsion: 10 parts by mass of hexafluorobutyl acrylate, 5 parts of methacrylic acid, 15 parts of methyl acrylate, and 6 parts of vinyltrioxysilane were dissolved in 150 parts of tetrahydrofuran , heated to 65°C, then added 0.03 parts of dibenzoyl peroxide to initiate the polymerization reaction, reacted for 3 hours, added 200 parts of distilled water, stirred evenly, and steamed tetrahydrofuran solvent at 85°C to obtain the organosilicon-modified Fluoroacrylate emulsion;

[0028] S2: Preparation of nano antifungal agent:

[0029] a. Dissolve 0.3 parts of silver nitrate and 0.5 parts of zinc nitrate in 100 parts of deionized water in parts by mass, add 5 parts of copper hydroxyphosphate, after ultrasonic dispersion, add dropwise 15 parts of ammonia solution with a mass concentration of 10%, and stir at 30°C After reacting for 2 hours, filte...

Embodiment 2

[0037] A method for laying wallpaper, comprising the steps of:

[0038] S1: Preparation of silicone-modified fluorine-containing acrylate emulsion: 12.5 parts by mass of hexafluorobutyl methacrylate, 6 parts of methacrylic acid, 17.5 parts of methyl acrylate, 8 parts of methylvinyldimethoxysilane Dissolve in 150 parts of tetrahydrofuran, heat to 65°C, then add 0.05 parts of dibenzoyl peroxide to initiate polymerization reaction, react for 5 hours, add 200 parts of distilled water, stir evenly, and steam the tetrahydrofuran solvent at 85°C to obtain the Silicone modified fluorinated acrylate emulsion;

[0039] S2: Preparation of nano antifungal agent:

[0040] a. Dissolve 0.5 parts of silver nitrate and 0.8 parts of zinc nitrate in 100 parts of deionized water in parts by mass, add 8 parts of copper hydroxyphosphate, after ultrasonic dispersion, add dropwise 17.5 parts of ammonia solution with a mass concentration of 10%, and stir at 25 °C After reacting for 3 hours, filterin...

Embodiment 3

[0048] A method for laying wallpaper, comprising the steps of:

[0049] S1: Preparation of silicone-modified fluorine-containing acrylate emulsion: 15 parts by mass of hexafluorobutyl methacrylate, 7 parts of methacrylic acid, 20 parts of methyl acrylate, 10 parts of γ-aminopropyltrimethoxysilane Dissolve in 150 parts of tetrahydrofuran, heat to 65°C, then add 0.06 parts of dibenzoyl peroxide to initiate polymerization reaction, react for 6 hours, add 200 parts of distilled water, stir evenly, and steam the tetrahydrofuran solvent at 85°C to obtain the Silicone modified fluorinated acrylate emulsion;

[0050] S2: Preparation of nano antifungal agent:

[0051] a. Dissolve 0.6 parts of silver nitrate and 1 part of zinc nitrate in 100 parts of deionized water in parts by mass, add 10 parts of copper hydroxyphosphate, after ultrasonic dispersion, add dropwise 20 parts of ammonia solution with a mass concentration of 10%, and stir at 25 °C After reacting for 6 hours, filtering, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com