Protein and amorphous metal organic framework compound and preparation method thereof

A metal-organic framework, amorphous technology, applied in biochemical equipment and methods, immobilized on/in organic carriers, immobilized on or in inorganic carriers, etc., can solve the problem of inability to use biologically active proteins and Amorphous metal-organic framework complexes, low activity of complexes, cumbersome synthesis steps, etc., to achieve mild conditions, high protein entrapment rate, and good protein stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1, the synthesis of metal organic framework compound

[0083] 1. Prepare an aqueous solution of zinc acetate hydrate with a concentration of 20mmol / L and an aqueous solution of 2-methylimidazole with a concentration of 80mmol / L, respectively, and ultrasonicate the resulting solutions for 15 minutes.

[0084] 2. Mix 1 mL each of the zinc ion solution and 2-methylimidazole solution obtained in step 1, and react at 25° C. for 1 hour.

[0085] 4. The product obtained in step 3 was separated by centrifugation, repeatedly washed with deionized water for 3 times, and the washed product was freeze-dried for 24 hours to obtain a metal organic framework compound.

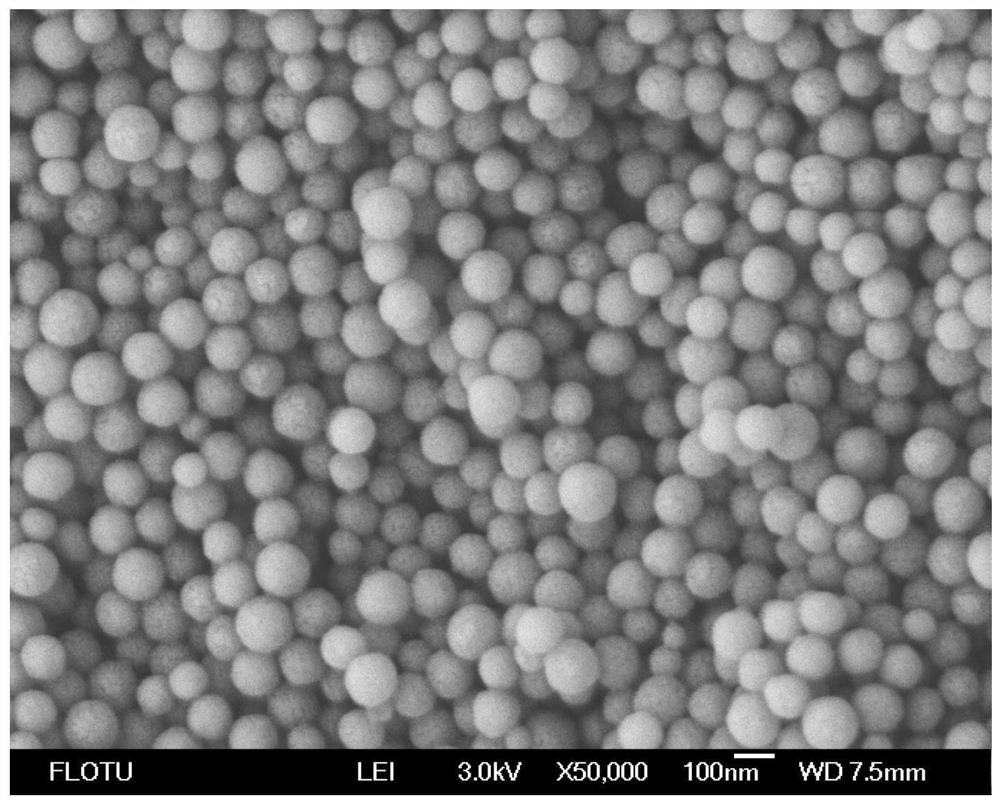

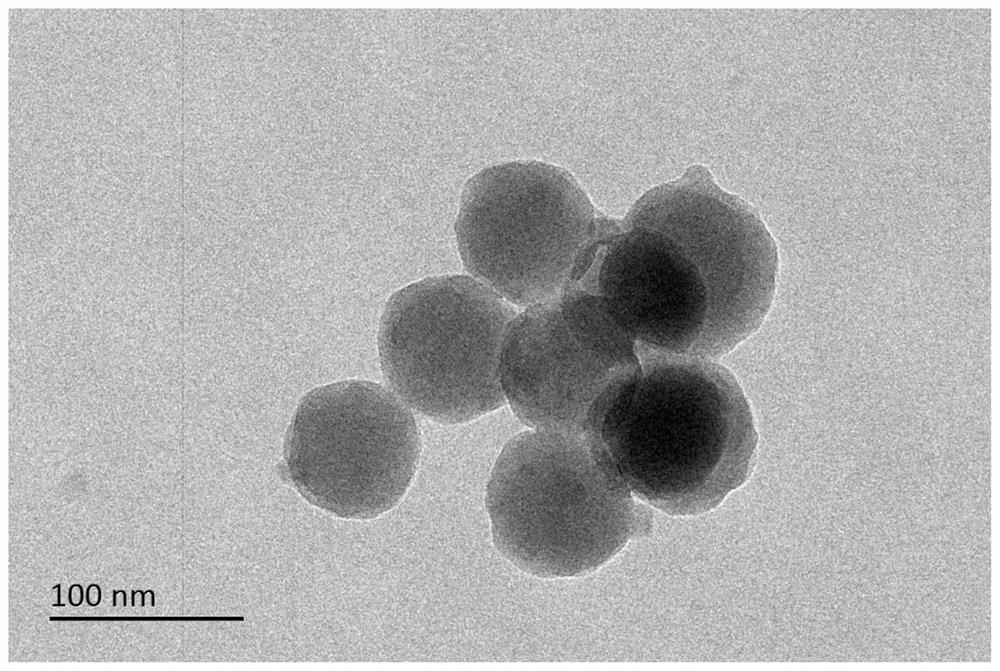

[0086] The scanning electron micrographs and transmission electron micrographs of the metal-organic framework compound prepared in this embodiment are as follows: figure 1 and figure 2 shown by figure 1 and figure 2 It can be seen that the main body shape of the obtained compound is spherical, and the ...

Embodiment 2

[0094] Embodiment 2, the synthesis of protein and amorphous metal-organic framework complex

[0095] 1. Prepare an aqueous solution containing 10 mg / mL of glucose oxidase.

[0096] 2. An aqueous solution of zinc acetate hydrate with a concentration of 20mmol / L and an aqueous solution of 2-methylimidazole with a concentration of 80mmol / L were respectively prepared, and the obtained solutions were ultrasonically treated for 15 minutes.

[0097] 3. Mix 100 μL of the solution obtained in step 1 with 1 mL each of the zinc ion solution and 2-methylimidazole solution in step 2, and react at 25° C. for 1 hour.

[0098] 4. The product obtained in step 3 was separated by centrifugation, repeatedly washed with deionized water for 3 times, and the washed product was freeze-dried for 8 hours to obtain a protein embedding rate of 100% in the product.

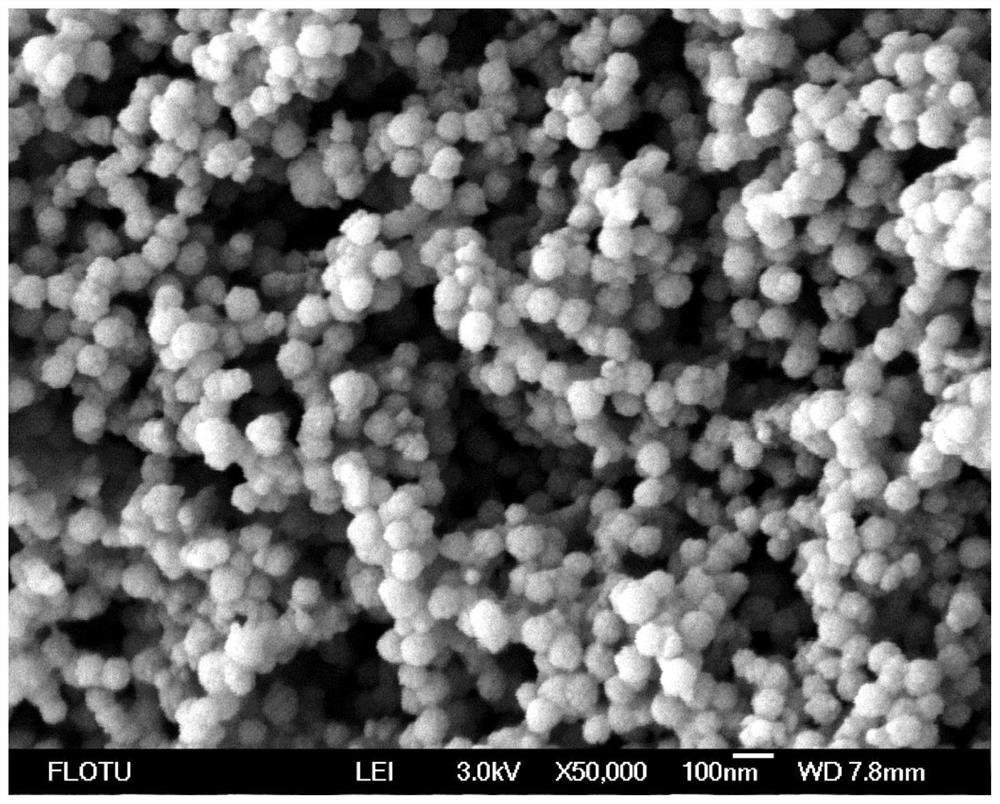

[0099] The scanning electron micrographs and transmission electron micrographs of the compound prepared in this embodiment are as follows: ...

Embodiment 3

[0107] Embodiment 3, the synthesis of compound alcohol dehydrogenase-metal organic framework compound

[0108] 1. Prepare 10mg / mL alcohol dehydrogenase solution.

[0109] 2. Prepare an aqueous solution of zinc acetate hydrate with a concentration of 40mmol / L and an aqueous solution of 2-methylimidazole with a concentration of 160mmol / L, respectively.

[0110] 3. Take 1 mL each of the zinc ion solution and 2-methylimidazole solution obtained in step 1 and 100 μL of the protein solution obtained in step 2, and react at 25°C for 30 min.

[0111] 4. The product obtained in step 3 was separated by centrifugation, repeatedly washed with deionized water for 3 times, and the washed product was freeze-dried for 8 hours to obtain a metal organic framework compound.

[0112] The transmission electron microscope figure of the complex of the compound alcohol dehydrogenase prepared by the present embodiment is as follows Figure 5 As shown, the scanning electron microscope image is shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com