Preparation method of injectable anti-fracturing degradable supramolecular hydrogel

A technology of hydrogel and deionized water, which is applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., and can solve the problem that hydrogel is not injectable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

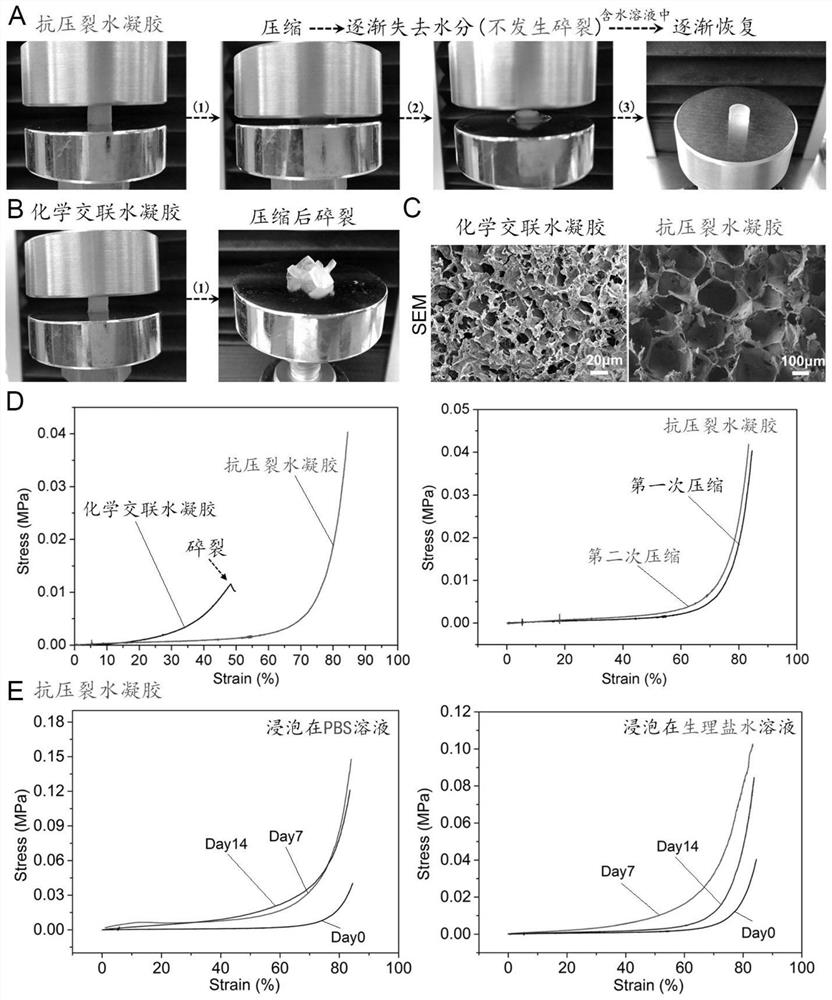

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) 1g chitosan is dissolved in 100mL volume fraction and is in the acetic acid aqueous solution of 1%, after dissolving, add 367 μ L methacrylic anhydride (MA) dropwise, react 24 hours under room temperature, obtain methacrylated chitosan ( CSMA).

[0036] (2) Dissolve 0.5g of 3-phosphonopropionic acid in 50mL of deionized water, add 5.33g of 2-(N-morpholine)ethanesulfonic acid monohydrate (MES monohydrate), add 0.9g of EDC (1-Ethyl -3-(3'-dimethylaminopropyl)carbodiimide) and 0.3g NHS (N-hydroxysuccinimide), fully dissolved and stirred at room temperature for 30 minutes.

[0037](3) Add the liquid after the reaction of chitosan and methacrylic acid in (1) step dropwise to the 3-phosphonopropionic acid solution in (2), stir while adding dropwise, after all dropwise add After reacting at room temperature for 24 hours, add 100mL deionized water to dilute, place the diluted solution in a 12-14kDa dialysis bag, and dialyze in deionized water at room temperature for 5 days...

Embodiment 2

[0040] (1) Dissolve 1 g of chitosan in 100 mL of 1% acetic acid aqueous solution by volume fraction, add 367 μL of methacrylic anhydride (MA) dropwise after dissolving, and react at room temperature for 24 hours.

[0041] (2) Dissolve 0.5g creatine phosphate in 50mL deionized water, add 5.33g 2-(N-morpholine)ethanesulfonic acid monohydrate (MES monohydrate), add 0.9g EDC (1-Ethyl-3-( 3'-dimethylaminopropyl)carbodiimide) and 0.3g NHS (N-hydroxysuccinimide), fully dissolved and stirred at room temperature for 30 minutes.

[0042] (3) Add the liquid after the reaction of chitosan and methacrylic acid in step (1) dropwise to the creatine phosphate solution in (2), stir while adding, and react at room temperature for 24 After 1 hour, add 100mL deionized water to dilute, place the diluted solution in a 12-14kDa dialysis bag, dialyze in deionized water at room temperature for 5 days, change the deionized water once every morning and evening, and keep stirring, freeze-dry after dialys...

Embodiment 3

[0045] (1) Dissolve 1 g of chitosan in 100 mL of 1% acetic acid aqueous solution by volume fraction, add 367 μL of methacrylic anhydride (MA) dropwise after dissolving, and react at room temperature for 24 hours.

[0046] (2) Dissolve 0.5g creatine phosphate in 50mL deionized water, add 5.33g 2-(N-morpholine)ethanesulfonic acid monohydrate (MES monohydrate), add 0.9g EDC (1-Ethyl-3-( 3'-dimethylaminopropyl)carbodiimide) and 0.3g NHS (N-hydroxysuccinimide), fully dissolved and stirred at room temperature for 30 minutes.

[0047] (3) Add the liquid after the reaction of chitosan and methacrylic acid in step (1) dropwise to the creatine phosphate solution in (2), stir while adding, and react at room temperature for 24 After 1 hour, add 100mL deionized water to dilute, place the diluted solution in a 12-14kDa dialysis bag, dialyze in deionized water at room temperature for 5 days, change the deionized water once every morning and evening, and keep stirring, freeze-dry after dialys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com