Preparation method of high-purity manganese sulfate

A manganese sulfate, high-purity technology, applied in manganese sulfate and other directions, can solve the problems of high production cost of high-purity manganese sulfate, complicated preparation process, and increased operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a kind of preparation method of high-purity manganese sulfate, comprises the following steps:

[0020] (1) removing heavy metal ions in the thick manganese salt solution to obtain a liquid phase product;

[0021] (2) Mix the liquid-phase product and bicarbonate to carry out precipitation of calcium, magnesium and manganese ions, and carry out solid-liquid separation after the concentration of manganese ions in the system≤0.2g / L to obtain crude manganese carbonate solid; the calcium, magnesium and manganese ions The pH value of the system during the precipitation process is ≤8.6;

[0022] (3) After the thick manganese carbonate solid is dispersed in water, carbon dioxide is introduced into the dispersion, and the refined manganese carbonate solid is obtained after solid-liquid separation;

[0023] (4) Wash the refined manganese carbonate solid and dissolve it in dilute sulfuric acid, then concentrate and crystallize to obtain high-purity manganese...

Embodiment 1

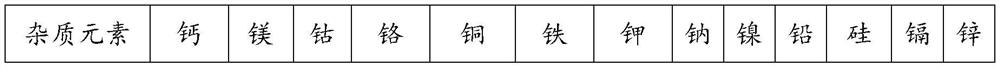

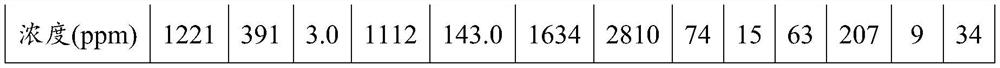

[0037] With feed grade manganese sulfate (Ca, Mg concentration is respectively 135ppm and 406ppm) as raw material, the concentration of each impurity in feed grade manganese sulfate is shown in Table 1.

[0038] Table 1. Concentration of each impurity element in feed grade manganese sulfate

[0039] Impurity elements calcium magnesium cobalt chromium copper iron Potassium sodium nickel lead silicon cadmium zinc Concentration (ppm) 1337 4058 326 32 0.0 269 8 585 617 43 155 3 2569

[0040] Dissolve 5 kg of feed grade manganese sulfate in 10 L of water, add solid sodium bicarbonate to adjust the pH of the solution to 5, and let it stand for 24 hours. Then restart stirring, add 100 grams of formane, stir for 2h, then filter. The filtrate is transferred to another 20L plastic barrel, and a sufficient amount of sodium bicarbonate solid (total amount is 2.8kg) is added under constant stirring condition, and the pH value of the...

Embodiment 2

[0046] Take 5L of manganese sulfate feed solution from Guizhou Neng Mine (see Table 3 for the concentration of impurity elements, and the concentration of manganese sulfate is 368g / L), add solid sodium bicarbonate under constant stirring, adjust the pH value of the solution to 7, let stand for 24h, filter . The filtrate was transferred to another 10L container, and 120g of sodium forma solid was added under continuous stirring, and after stirring for 2 hours, it was left to stand for 24 hours and filtered. Under constant stirring condition, add sodium bicarbonate solid (total addition is 1450g) in filtrate, the pH value of solution is controlled to below 8.6 with the mode of the sodium hydroxide solution of 100g / L. Wait for the manganese ion concentration in the solution to be less than 0.2g / L, leave standstill, treat that after most of the manganese carbonate precipitation settles to the bottom of the container, dump and discard the last clear liquid, filter, and collect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com