Flocculating agent composition for preparing ray emulsion and desalination and concentration method

A technology of composition and flocculant is applied in the field of preparation of ray silver halide emulsion to achieve the effects of lightening processing load, reducing production energy consumption and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

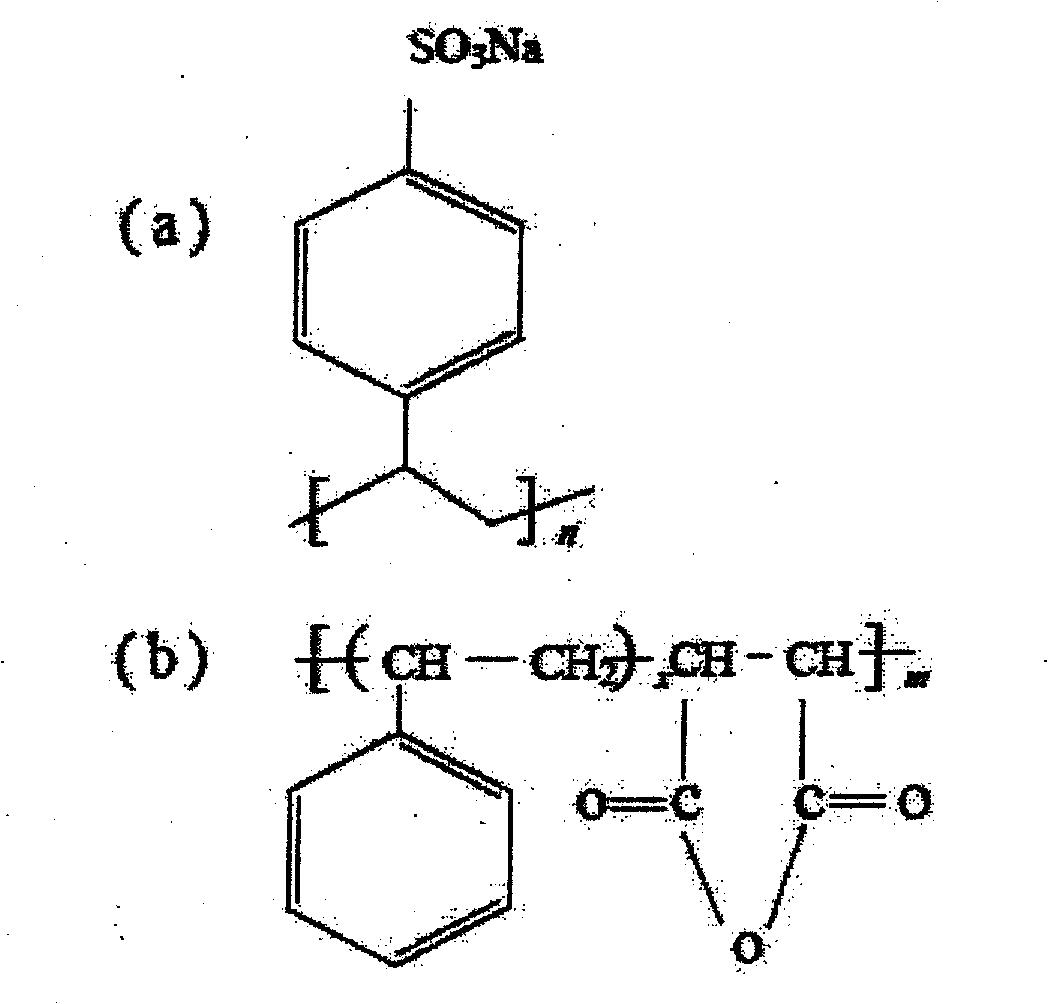

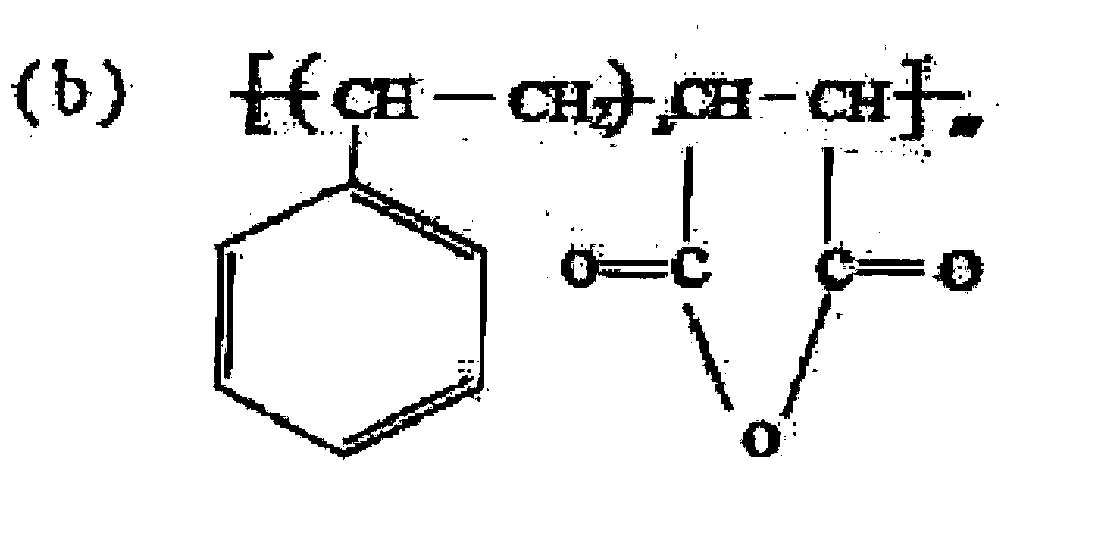

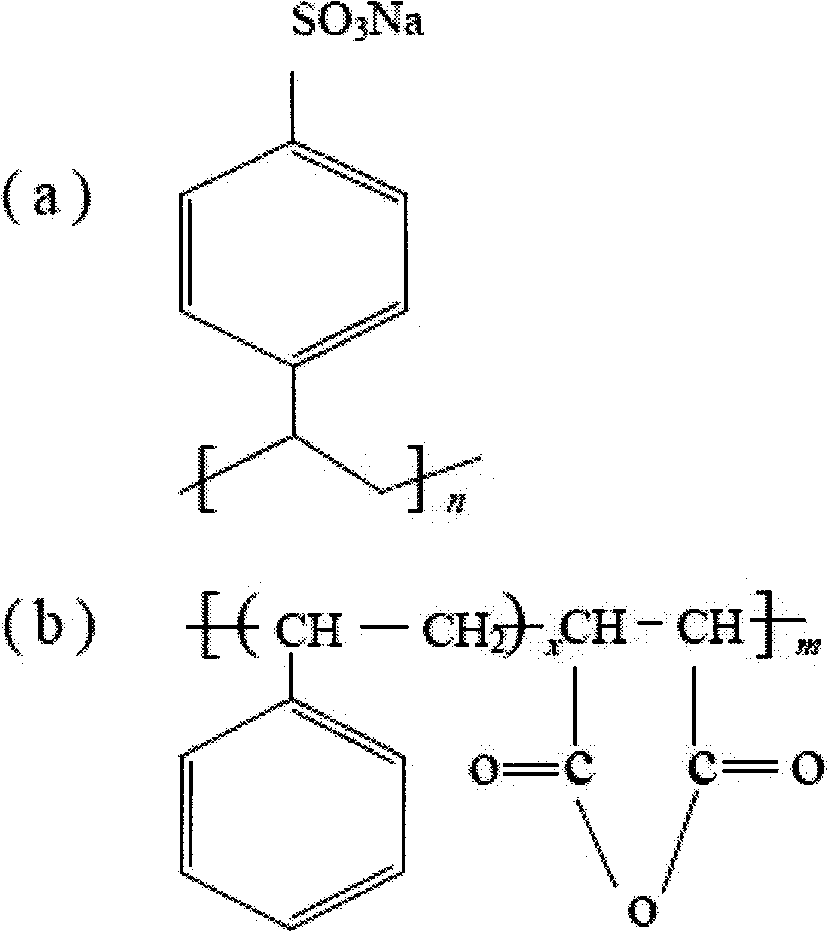

Method used

Image

Examples

example 1

[0029] Example 1: Ammonia-based silver halide radiation-sensitive emulsion was prepared by conventional emulsification. Among them, the silver halide can be pure silver bromide, or silver bromoiodide (Br - :I - molar ratio greater than 80:20; Br:I molar ratio greater than 95:5 is better), or bromoiodosilver chloride (Br - :I - :Cl - The molar ratio is about 98:1:1). Preparation method: Add silver solution (containing 140L deionized water) to the base liquid (containing 150L deionized water, 12kg inert photographic gelatin, 0.6kg potassium iodide, 0.3kg potassium chloride and 44kg ammonium bromide) at 55°C for 5 minutes at a constant flow rate , silver nitrate 32kg, ammonia water 16L and ammonium nitrate 8kg); after an interval of 2 minutes, add the silver solution (containing deionized water 140L, silver nitrate 32kg, ammonia water 16L and ammonium nitrate 8kg) at a constant flow rate for 15 minutes; adjust the pH value to 6.5 with acetic acid -8, the first maturation of ...

example 2

[0033] Example 2: The primary ripening of the emulsion is the same as in Example 1.

[0034]Desalination stage: Add 6% flocculation (or sedimentation) agent conforming to the b structure to the primary mature emulsion, 33kg; add acid to adjust the pH value to below 4.5, and leave the gelatin silver halide emulsion below 20°C to achieve a desalination concentration (detection The conductivity of the dumped mother liquor and the concentration of silver ions); once the sedimented medicine cake is added to 200L deionized water (not exceeding 60°C), the medicine cake is completely dissolved after the alkali is adjusted to a pH value above 7.5; after stirring for more than 10 minutes, add acid again to adjust When the pH value is below 4.5, add 150L of low-temperature deionized water below 20°C, and let the gelatin silver halide emulsion stand below 20°C to achieve secondary desalination and concentration (detect the conductivity and silver ion concentration of the dumped mother liqu...

example 3

[0037] Example 3: The primary ripening of the emulsion is the same as in Example 1.

[0038] Desalination stage: Add 4% flocculation (or sedimentation) agent conforming to the c structure to the primary mature emulsion, 35kg; add acid to adjust the pH value to below 4.5, and leave the gelatin silver halide emulsion below 20°C to achieve a desalination concentration (detection The conductivity of the dumped mother liquor and the concentration of silver ions); once the sedimented medicine cake is added to 200L deionized water (not exceeding 60°C), the medicine cake is completely dissolved after the alkali is adjusted to a pH value above 7.5; after stirring for more than 10 minutes, add acid again to adjust When the pH value is below 4.5, add 150L of low-temperature deionized water below 20°C, and let the gelatin silver halide emulsion stand below 20°C to achieve secondary desalination and concentration (detect the conductivity and silver ion concentration of the dumped mother liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com