A kind of composite coating molding preparation method of ceramic core

A technology of ceramic cores and coatings, which is applied in the direction of casting molding equipment, cores, and mold components, which can solve the problems of low efficiency, high cost, and increased casting cost and reject rate of ceramic cores, so as to ensure removability , simple method, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

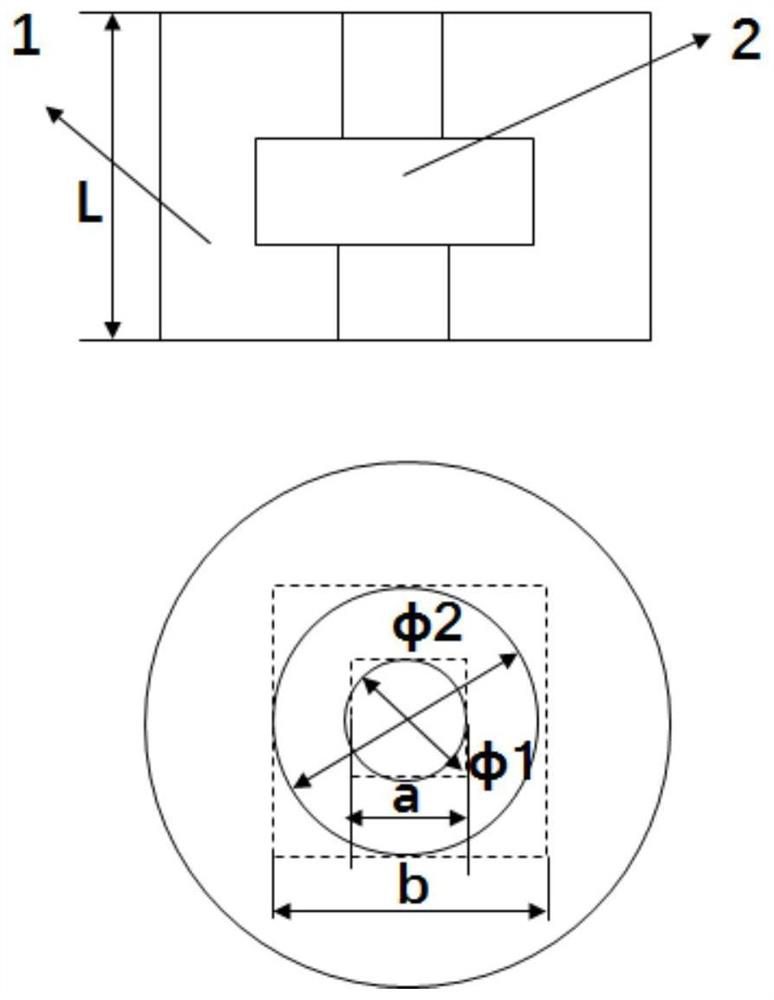

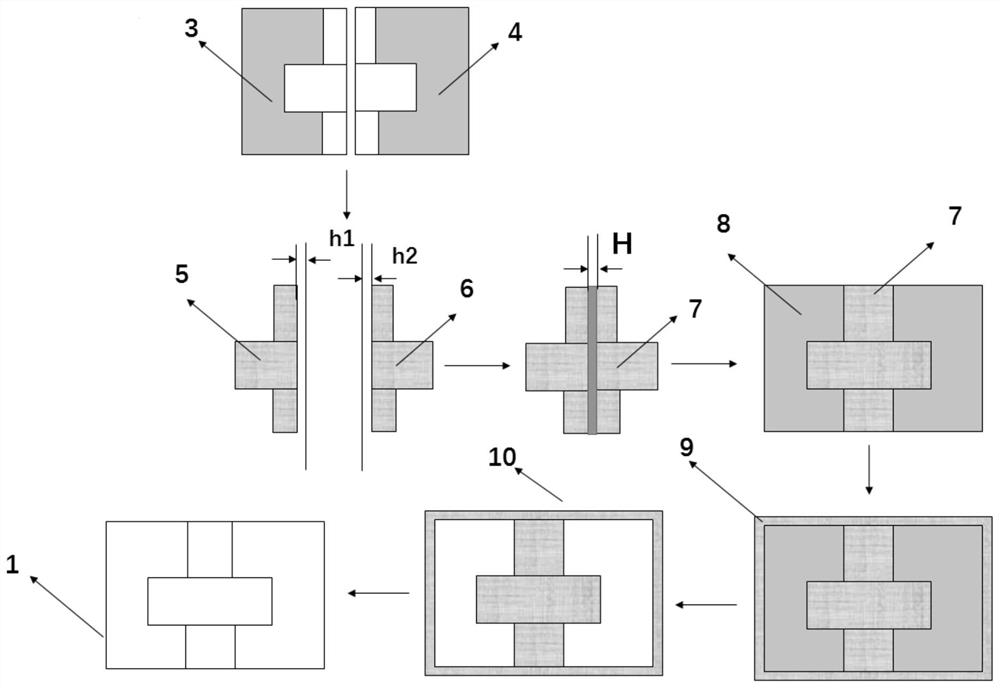

[0041] 1) The inner cavity of the casting contains multiple through holes, the diameter of the through hole is 2mm, the height of the through hole (that is, the radial distance between the two ends of the through hole) is 2mm, the maximum diameter of the concave inner cavity is 50mm, and the height of the inner cavity of the casting is 150mm. Partitioning is carried out at the largest cross-section of the inner cavity structure of the casting, and the left and right half core wax molds are prepared that are completely consistent with the shape and size of the inner cavity structure of the casting (see image 3 ), wherein the inner dimensions corresponding to the concave parts of the left and right wax molds are exactly the same as the outer structure dimensions of the ceramic core. Prepared by injection molding process, the injection pressure is 3 atmospheres, the injection time is 10 seconds, and the pressure holding time is 10 seconds.

[0042]2) prepare the core slurry coat...

Embodiment 2

[0047] 1) The inner cavity of the casting contains multiple through holes, the diameter of the through hole is 10mm, the height is 12mm, the maximum diameter of the concave inner cavity is 50mm, and the height of the inner cavity of the casting is 300mm. Partitioning is carried out at the largest cross-section of the inner cavity structure of the casting, and the left and right half core wax molds are prepared that are exactly the same as the inner cavity structure of the casting. The structural dimensions are exactly the same. Prepared by injection molding process, the injection pressure is 3 atmospheres, the injection time is 10 seconds, and the pressure holding time is 20 seconds.

[0048] 2) prepare the core slurry coating, the coating is prepared by the mixed powder of quartz glass powder and zircon powder and silica sol, wherein the mass ratio of quartz glass powder and zircon powder is 90%: 10%, the mixed powder and The mass ratio of silica sol is 80%:20%, the particle...

Embodiment 3

[0053] 1) The inner cavity of the casting contains multiple through holes, the side length of the through holes is 20mm, the height is 20mm, the maximum diameter of the concave inner cavity is 100mm, and the height of the inner cavity of the casting is 100mm. Partitioning is carried out at the largest cross-section of the inner cavity structure of the casting, and the left and right half-core wax molds are prepared that are completely consistent with the shape and size of the inner cavity structure of the casting. The shape and size of the core are exactly the same. Prepared by injection molding process, the injection pressure is 5 atmospheres, the injection time is 60 seconds, and the pressure holding time is 60 seconds.

[0054] 2) prepare the core slurry coating, the coating is prepared by the mixed powder of quartz glass powder and zircon powder and silica sol, wherein the mass ratio of quartz glass powder and zircon powder is 60%:40%, the mixed powder and The mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com