A method for repairing threaded holes with an insert

A technology of threaded holes and inserts is applied in the field of repairing and processing of mechanical parts to achieve the effect of avoiding thread deformation, avoiding loosening and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for repairing threaded blind holes with inserts, comprising the steps of:

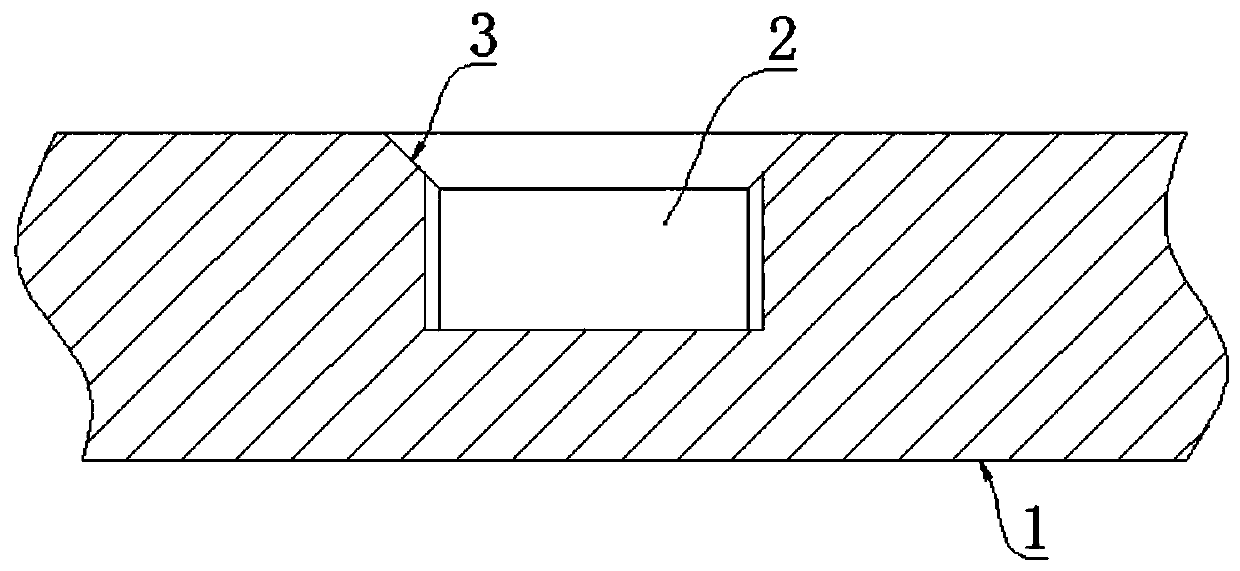

[0041] S1. Reaming and eliminating defects: expand the threaded hole A2 to be repaired to the pre-designed insert size, eliminate the defective part, and spot-face a 30° chamfer 3 on the top edge of the threaded hole A2;

[0042] S2. Preparation of filling parts: select the same or similar material as the base metal 1, and turn out bolts suitable for the threaded hole A2;

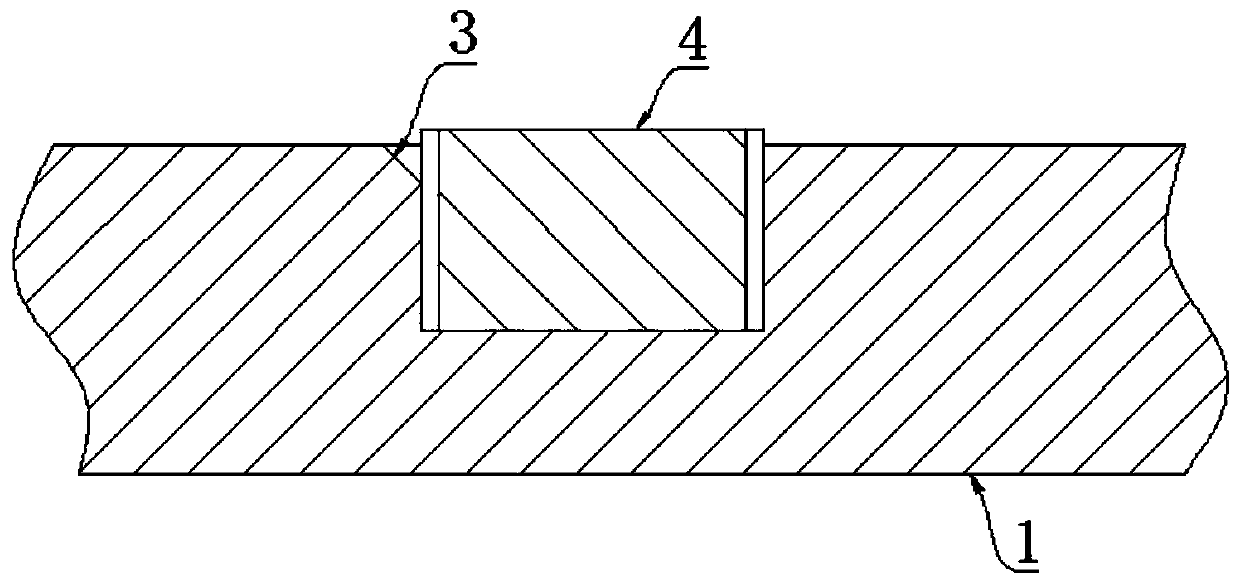

[0043] S3. Filling the threaded hole: apply high-strength thread-locking glue on the periphery of the bolt, and then assemble it into the threaded hole A2;

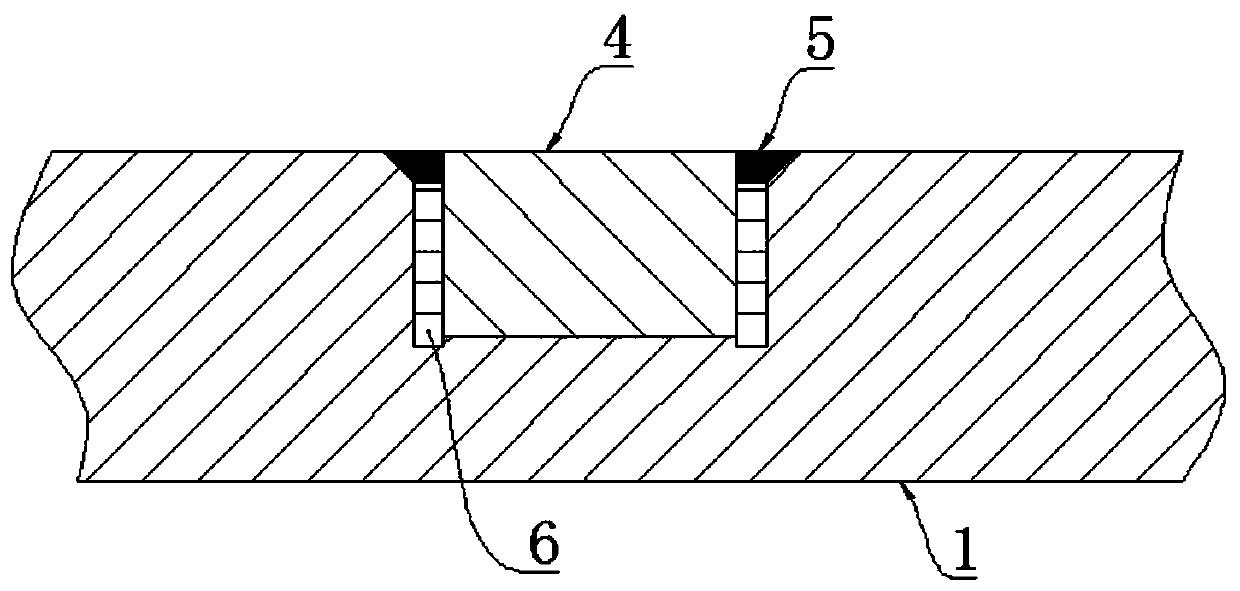

[0044] S4. Welding: Weld the bolt at the chamfer 3 according to the welding parameters, and weld the chamfer 3 to the full, and control the welding deformation during the welding process;

[0045] S5. Initial leveling: milling off the part of the filling part 4 that exceeds the surface of the base material 1, and reserve a margin for subsequent processes;

[0...

Embodiment 2

[0054] A method for repairing threaded blind holes with inserts, comprising the steps of:

[0055] S1. Reaming and eliminating defects: expand the threaded hole A2 to be repaired to the pre-designed insert size, eliminate the defective part, and spot-face a 60° chamfer 3 on the top edge of the threaded hole A2;

[0056] S2. Prepare filler: select the same or similar material as the base material 1, and turn out filler 4 that is compatible with the threaded hole A2;

[0057] S3. Filling the threaded hole: apply high-strength thread-locking glue on the 4 sides of the filler, and then assemble it into the threaded hole A2;

[0058] S4. Welding: welding the filler 4 at the chamfer 3 according to the welding parameters, and welding the chamfer 3 completely, and controlling the welding deformation during the welding process;

[0059] S5. Initial leveling: milling off the part of the filling part 4 that exceeds the surface of the base material 1, and reserve a margin for subsequent ...

Embodiment 3

[0066] A method for repairing threaded blind holes with inserts, comprising the steps of:

[0067] S1. Reaming and eliminating defects: expand the threaded hole A2 to be repaired to the pre-designed insert size, eliminate the defective part, and spot-face a 45° chamfer 3 on the top edge of the threaded hole A2;

[0068] S2. Prepare filler: select the same or similar material as the base material 1, and turn out filler 4 that is compatible with the threaded hole A2;

[0069] S3. Filling the threaded hole: apply high-strength thread-locking glue on the 4 sides of the filler, and then assemble it into the threaded hole A2;

[0070] S4. Welding: welding the filler 4 at the chamfer 3 according to the welding parameters, and welding the chamfer 3 completely, and controlling the welding deformation during the welding process;

[0071] S5. Initial leveling: milling off the part of the filling part 4 that exceeds the surface of the base material 1, and reserve a margin for subsequent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com