Preparation process of printed circuit board based on magnetic coverage technology

A technology of printed circuit board and preparation process, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit coating, etc., and can solve problems such as uneven thickness of solder resist ink layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

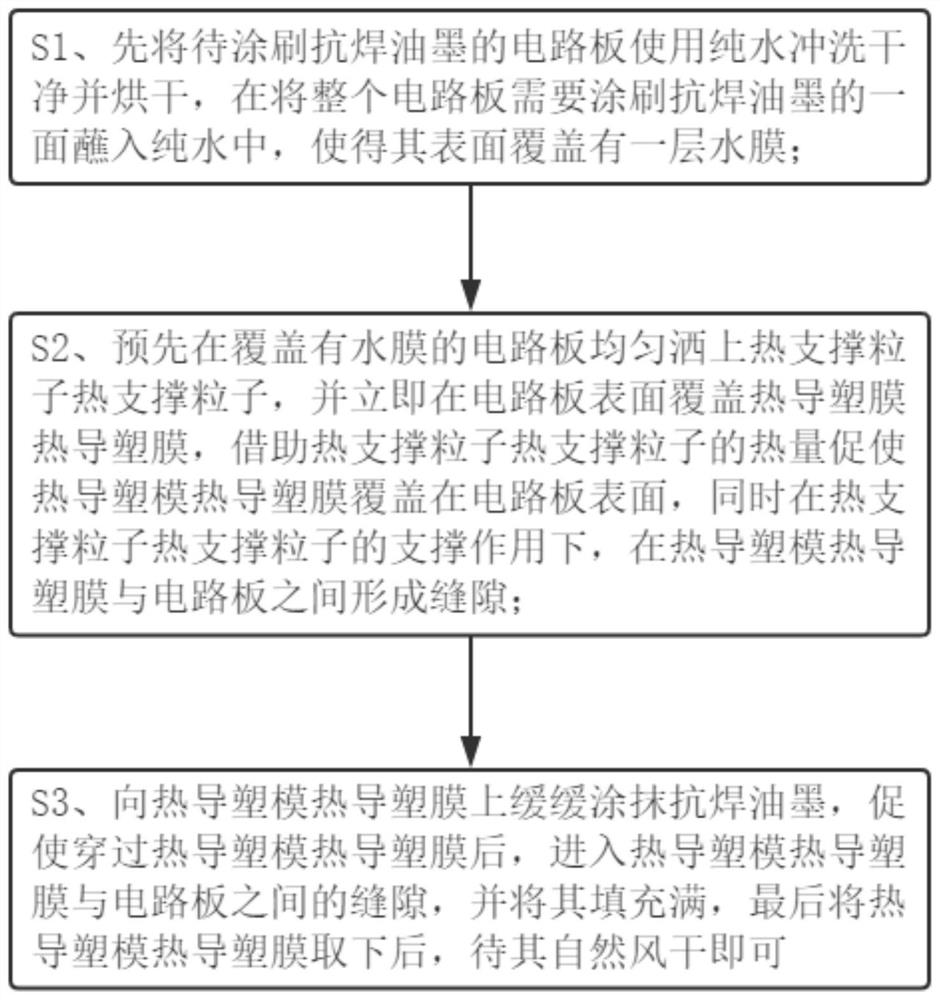

[0041] see Figure 1-4 , a preparation process of a printed circuit board based on magnetic covering technology, comprising the following steps:

[0042] S1. First, rinse the circuit board to be coated with solder resist ink with pure water and dry it, then dip the side of the entire circuit board that needs to be coated with solder resist ink into pure water so that its surface is covered with a layer of water film;

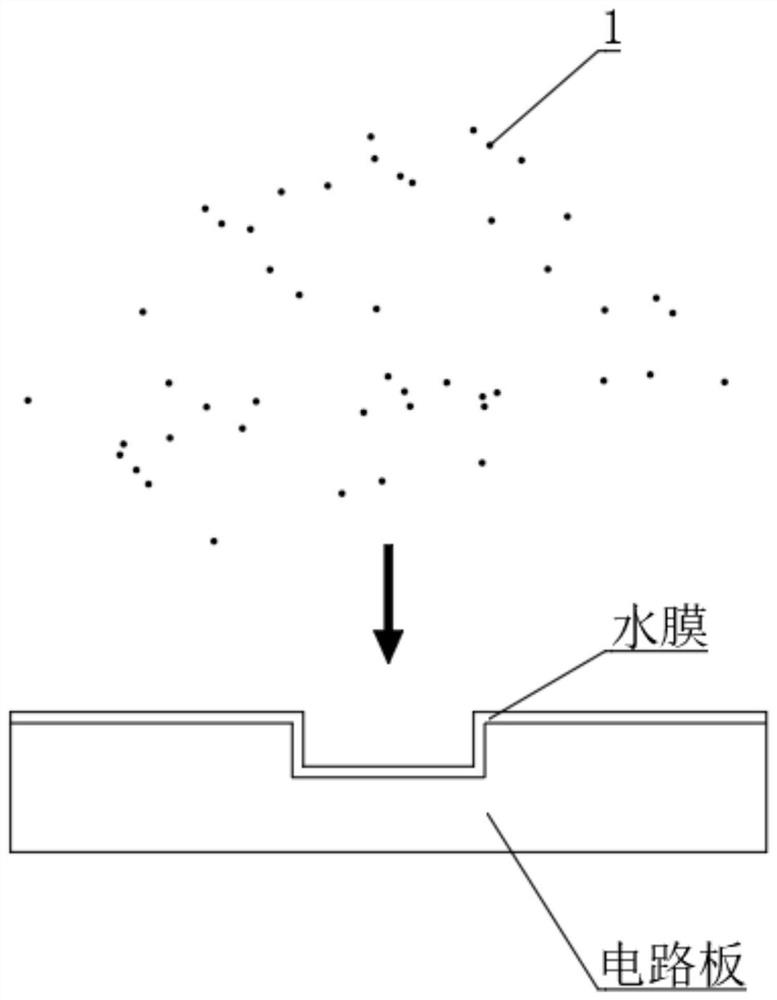

[0043] S2. Sprinkle heat-supporting particles evenly on the circuit board covered with water film in advance. Heat-supporting particles 1, and immediately cover the surface of the circuit board with heat-conducting plastic film Heat-conducting plastic film 2, promote The thermal conductive plastic film 2 of the thermal conductive mold covers the surface of the circuit board, and at the same time, under the support of the thermal support particles 1, a gap is formed between the thermal conductive plastic film 2 of the thermal conductive mold and the circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com