Isolating membrane and manufacturing method thereof

A manufacturing method and technology of isolation film, which can be applied to electrical components, circuits, battery pack components, etc., can solve the problems of reducing battery efficiency, reducing the permeability of isolation film, and poor battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Add 50 grams of alumina (Al2O3) particles (AHP 200, d50 is about 0.6 microns, purchased from Japan Light Metal, Japan) into 100 grams of polyacrylate amine dispersant aqueous solution with a concentration of 0.5%, and stir to obtain a concentration of 50%. Alumina dispersion aqueous solution. Next, 5 grams of water-soluble polyacrylate (BM-2000M, available from ZEON, Japan) and 1 gram of silicone surfactant (BYK-349, available from BYK-Chemie GmbH, Germany) were added as wetting agents to the aforementioned Alumina is dispersed in an aqueous solution to form a heat-resistant coating slurry. Then, the heat-resistant coating slurry was coated on the non-porous PP / PE / PP three-layer precursor substrate with a thickness of 21 micrometers (μm), and then the coated non-porous PP / PE / PP three-layer was coated. The layer precursor substrate is subjected to a cold extension process along the first direction (the extension ratio is 45% and the extension temperature is 25°C), and t...

Embodiment 2

[0076] A porous isolation film with a heat-resistant layer was prepared in the same manner as in Example 1, except that the stretching ratio of the cold stretching process was changed to 30%, and the stretching ratio of the hot stretching process was changed to 140%. The film retracts by 15%.

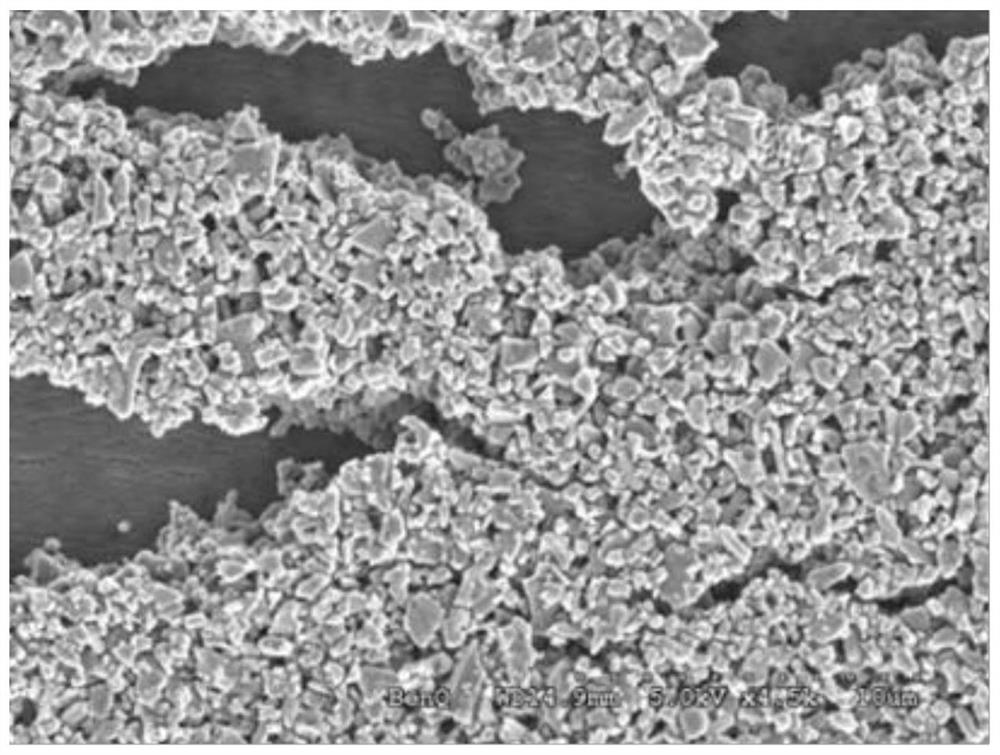

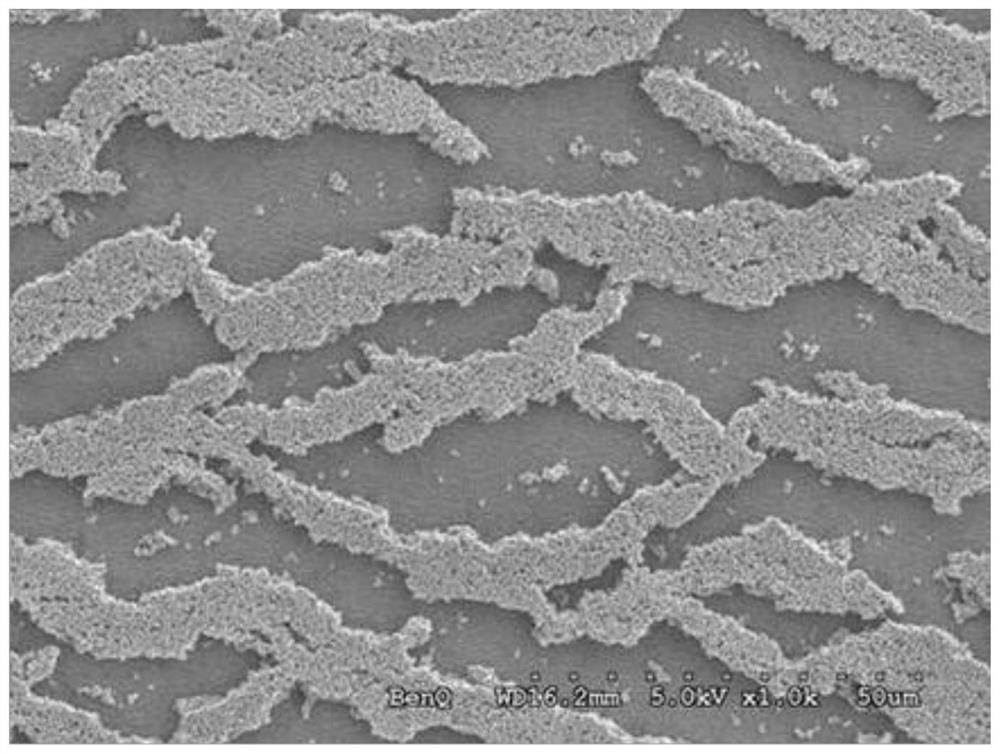

[0077] The surface and cross section of the separator were observed with a scanning electron microscope (SEM). The surface image of SEM at 1,000 magnification is as follows image 3 As shown, the surface image of SEM at 4,500 magnification is as follows Figure 4 As shown, the cross-sectional view of SEM at 2,000 magnification is as follows Figure 5 shown.

Embodiment 3

[0079] A porous isolation film with a heat-resistant layer was prepared in the same manner as in Example 1, except that the stretching ratio of the cold stretching process was changed to 30%, and the stretching ratio of the hot stretching process was changed to 150%. The film retracted by 11%.

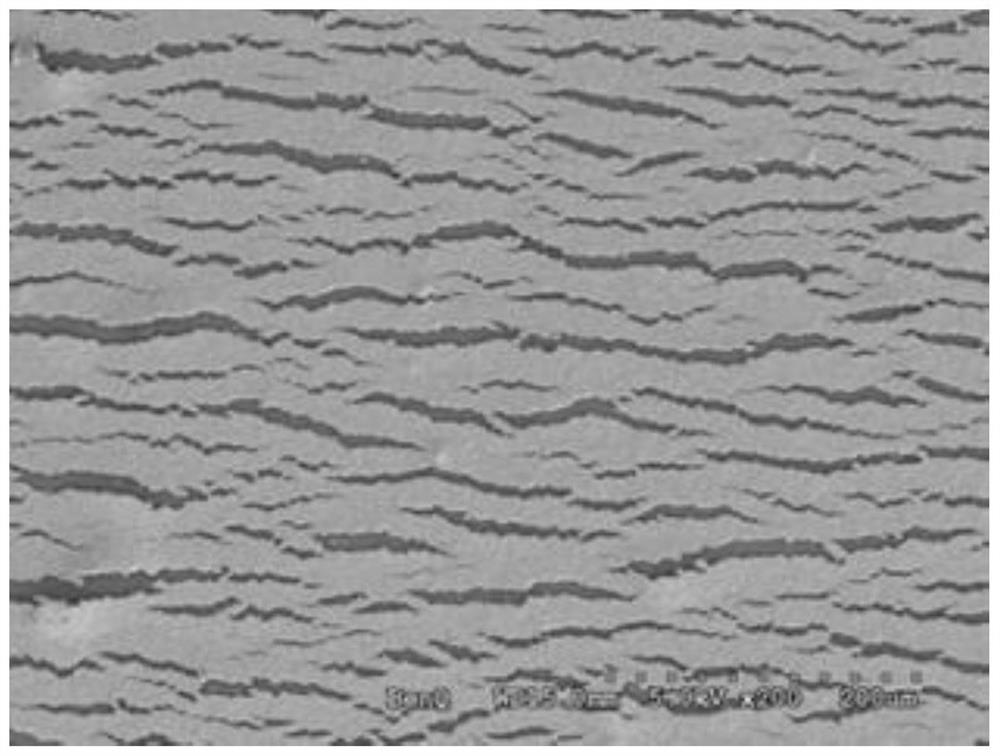

[0080] The surface of the separator was observed with a scanning electron microscope (SEM). The surface image of SEM at 200 magnification is as follows Image 6 As shown, the surface image of SEM at 600 magnification is as follows Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com