Sine-wave-shaped micro-channel heat exchanger with micro-cavity structures and manufacturing method thereof

A technology of microchannel heat exchanger and sine wave, which is applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of complicated processing steps, long processing time, structural wear, etc., and achieve the processing technology Simple steps, improved heat dissipation efficiency, enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

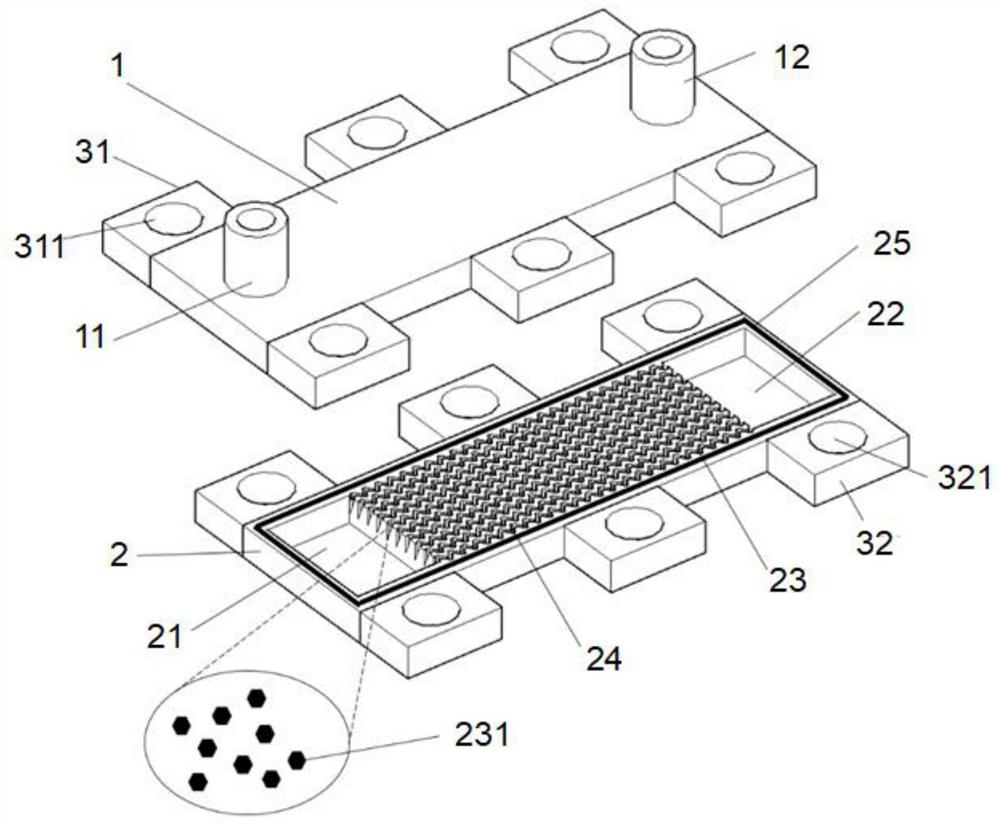

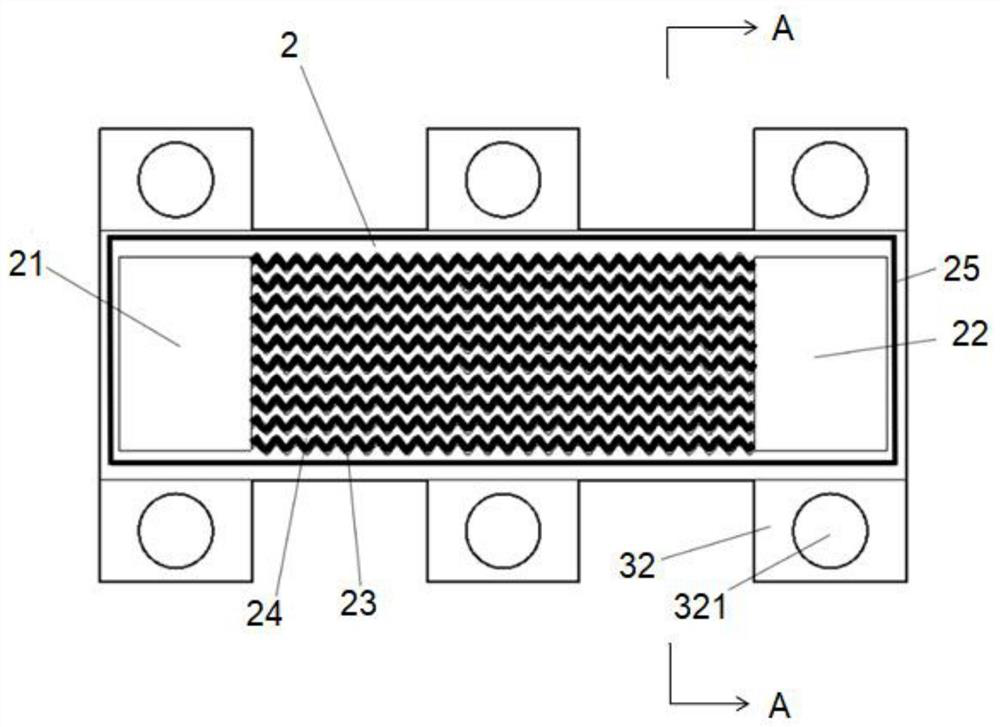

[0040] see Figure 1 to Figure 4 As shown, the present invention provides a sinusoidal microchannel heat exchanger with a micro-cavity structure, including a cover plate 1 and a microchannel heat sink 2 that are bonded together up and down, and the cover plate 1 and the microchannel heat sink 2 The room is fixedly connected by the fixing device 3;

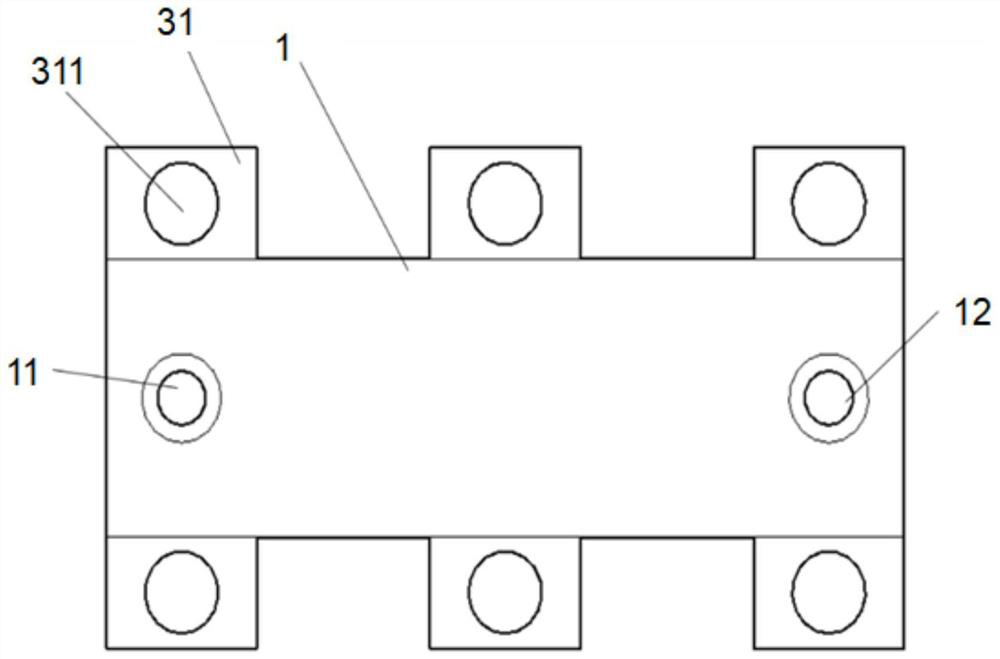

[0041] A coolant inlet 11 and a coolant outlet 12 are opened on the cover plate 1, see figure 2 As shown, the cover plate 1 is a metal cover plate. In this embodiment, the material of the cover plate 1 is copper, and the size of the cover plate 1 is 15mm*35mm. In this embodiment, the coolant inlet 11 and the coolant outlet 12 It is arranged at both ends of the long side of the cover plate 1, and the coolant inlet 11 and the coolant outlet 12 are circular columns protruding from the upper surface of the cover plate 1, and the distance between the center of the coolant inlet 11 and the left edge of the cover plate 1 is 1.5mm, 7.5mm ...

Embodiment 2

[0048] Based on the same inventive concept, see Image 6 As shown, the present invention also provides a method for manufacturing a sinusoidal wave microchannel heat exchanger with a micro-cavity structure, comprising the following steps:

[0049] S1: Provide polished first metal plate and second metal plate, the first metal plate and the second metal plate are copper plates, the size of the first metal plate is length 50mm*width 50mm*height 15mm, the second metal plate The size is length 50mm*width 50mm*height 5mm;

[0050] S2: Clamp the first metal plate on the micro-milling processing machine tool, use the micro-milling technology to process the coolant inlet and coolant outlet on the first metal plate, and make the cover plate. In this embodiment, the cover plate is long Both sides of the side are respectively symmetrically provided with a first fixed block, and a first mounting hole is provided on the first fixed block, so step S2 is specifically as follows:

[0051] Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com