Welding type single piece piston in forged steel with close internal cooling oil pocket and fabricating method

A technology of integral piston and manufacturing method, applied in the direction of piston, manufacturing tool, quenching agent, etc., can solve the problem that the aluminum piston cannot meet the high power of the engine, and achieve the effect of small deformation, ensuring work reliability and increasing structural rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

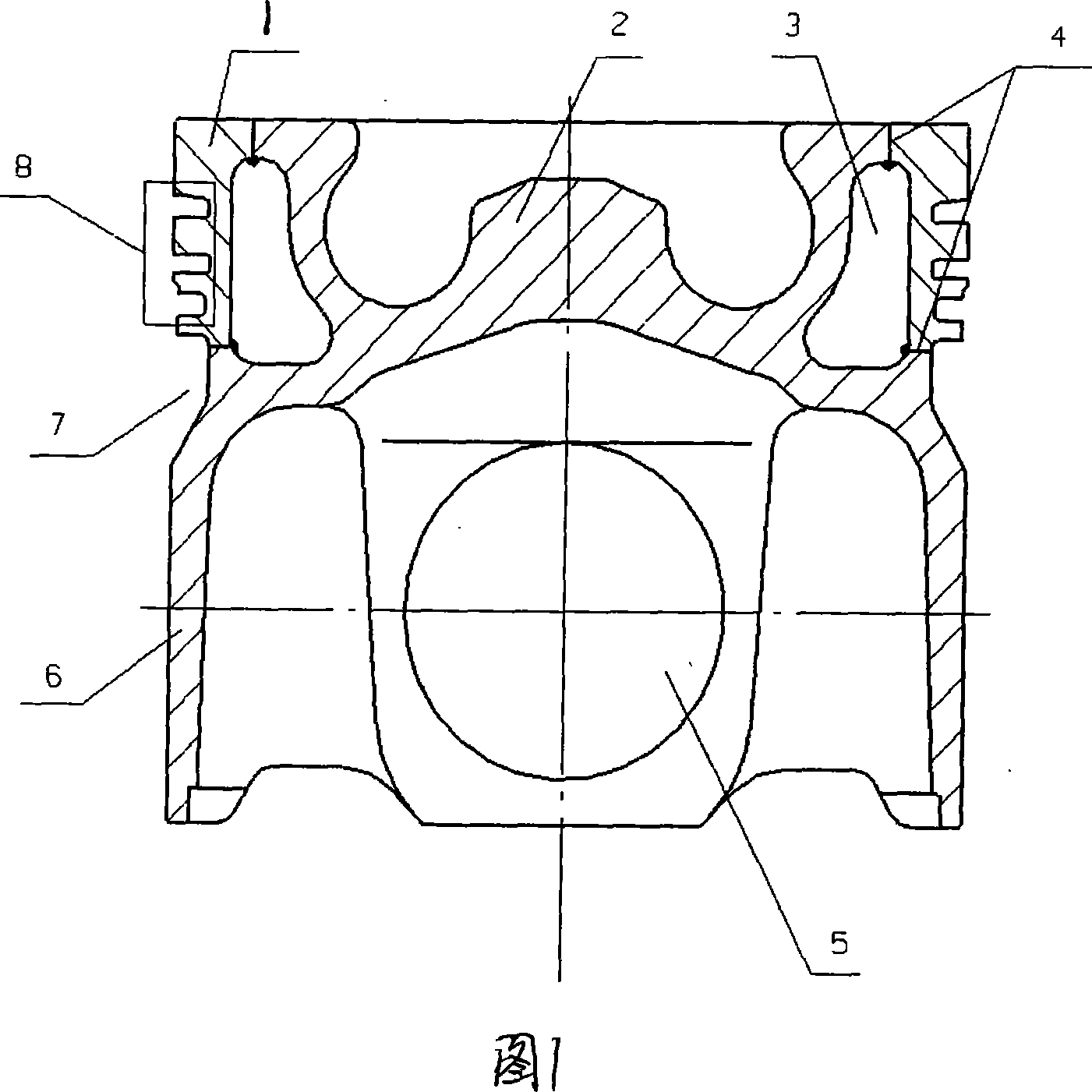

[0028] In FIG. 1 , the piston body 2 and the piston ring body 1 are separately forged components, and the two are welded together by laser. There is one or more ring grooves 8 on the piston ring body 1, and the laser welding zone 4 of the piston body 2 forms two annular areas, the upper and lower ring areas, and an internal cooling oil chamber 3 is formed between it and the piston body 2, and the oil chamber 3 passes through Two or three oil inlet and outlet holes communicate with the inner cavity of the piston. An annular groove 7 is arranged on the skirt 6 of the piston body 2, and a pin hole 5 is arranged at the bottom of the piston body 2, and concave deviations are forged on both sides of the pin hole 5.

[0029] The manufacture method of product of the present invention is:

[0030] ①. Separately forge the piston body and piston ring, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com